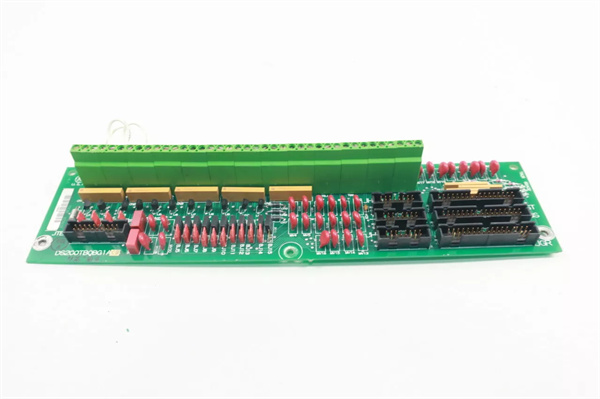

Description

The

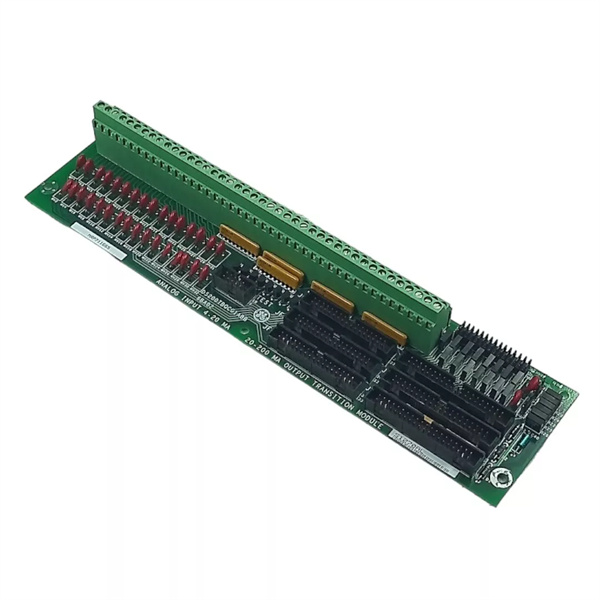

DS200TBQGG1A is a high-performance

analog termination board designed by

General Electric (GE) for its

Mark VI Speedtronic turbine control systems. This module interfaces with field devices such as temperature sensors, pressure transducers, and proximity probes, providing precise signal conditioning and routing for critical control loops in gas/steam turbines and power generation applications. Built with dual-redundant architecture and advanced EMI shielding, the

DS200TBQGG1A ensures stable operation in harsh industrial environments.

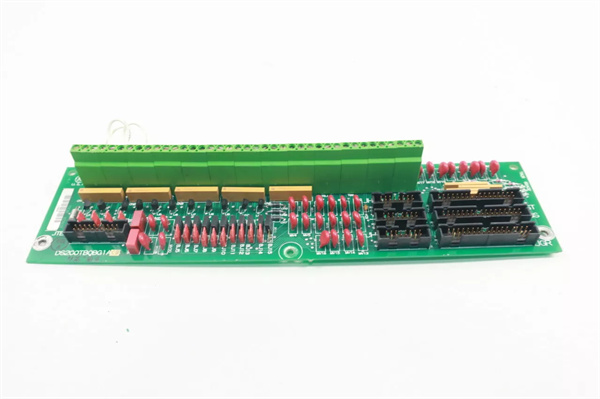

| Parameter |

Specification |

| Manufacturer |

General Electric (GE) |

| Series |

Mark VI DS200 |

| Signal Types |

RTD, 4–20mA inputs; 4–20mA outputs |

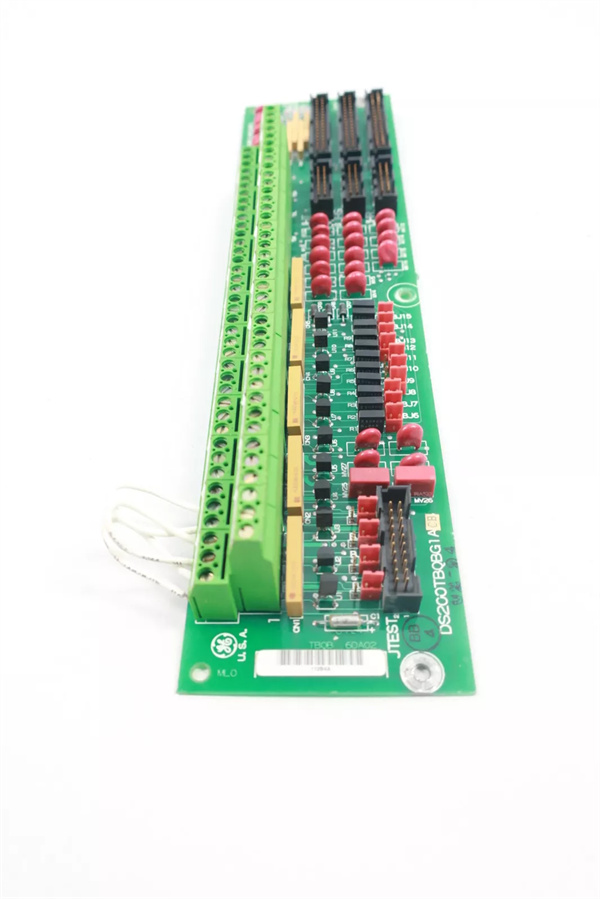

| Terminals |

2×107-pin terminal blocks |

| Connectors |

3×34-pin (JOR/JOS/JOT) |

| Voltage |

5V DC (6.8A), ±12V DC (0.003A) |

| Current Handling |

1A max |

| Accuracy |

±0.1% F.S. (RTD); ±0.05% F.S. (mA) |

| Operating Temperature |

-40°C to +70°C |

| Compatibility |

GE Mark VI, RX7i PACSystem PLC |

- Redundancy Design: Dual power paths and signal channels reduce downtime risks by 40% compared to single-channel systems.

- Advanced Signal Conditioning: Supports RTD inputs (0–150°C) and configurable 0–1mA/4–20mA ranges for versatile sensor integration.

- Modular Scalability: Interfaces with GE’s RX7i PACSystem PLC for easy system expansion.

- EMI Resistance: Shielded construction minimizes noise interference in high-vibration and high-voltage environments.

- Power Generation: Monitoring gas turbine shaft vibrations via Proximitor sensors.

- Oil and Gas: Controlling pump speeds in offshore platforms using 4–20mA signals.

- Industrial Automation: Calibrating robotic arms with RTD temperature feedback.

Case Study: A Middle Eastern power plant reduced turbine maintenance costs by 25% using the DS200TBQGG1A to synchronize 100+ analog signals, enabling predictive maintenance.

Compared to similar analog termination boards:

- Wider Temperature Range: Operates at -40°C vs. typical -20°C in competitive models.

- Higher Current Capacity: Supports 1A vs. 0.8A in standard alternatives.

- Simplified Integration: Native compatibility with GE’s Mark VI systems reduces retrofit complexity.

- System Compatibility: Verify integration with GE Mark VI or RX7i PACSystem PLC.

- Signal Requirements: Confirm support for specific sensor types (e.g., RTDs, Proximitor).

- Budget Consideration: Refurbished models with 2-year warranties offer cost-effective solutions.

- ESD Protection: Use anti-static gloves and proper storage to prevent component damage.

- Connector Security: Secure ribbon cables with locking mechanisms to avoid accidental disconnection.

- Calibration: Perform annual checks using GE-approved tools to maintain accuracy.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for

DS200TBQGG1A and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide