Description

The

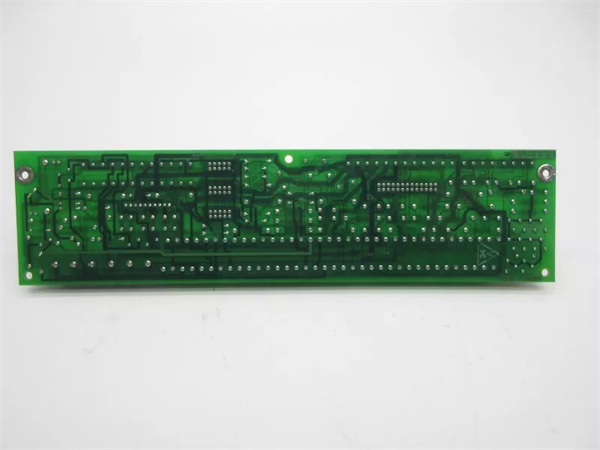

DS200TBQEG1B is an advanced analog termination board developed by General Electric (GE) for its Mark V and Mark VI turbine control systems. This board plays a crucial role in industrial automation, especially in power generation and related heavy – industry sectors. It is designed to interface with various field devices such as sensors and actuators, providing precise signal conditioning and routing for analog signals.

The core function of the DS200TBQEG1B is to convert and manage signals from sources like Proximitor sensors, LVDT (Linear Variable Differential Transformer) sensors, and 4 – 20 mA transmitters. By doing so, it ensures that the control system receives accurate and reliable data, which is essential for the proper operation of turbines and other industrial equipment. The board’s design allows it to work in harsh industrial environments, with features to resist electromagnetic interference (EMI) and temperature variations.

| Parameter |

Specification |

| Manufacturer |

General Electric (GE) |

| Series |

Mark V/VI DS200 |

| Input Signal Types |

Proximitor, LVDT, 4 – 20 mA |

| Output Signal Types |

4 – 20 mA |

| Terminal Blocks |

2 terminal blocks with 107 signal terminals each |

| Connectors |

3 x 34 – pin connectors |

| Test Points |

3 test points (TP1, TP2, TP3) |

| Power Supply |

24V DC ±10% |

| Operating Temperature Range |

– 40°C to +70°C |

| Dimensions |

Approximately 170 mm x 90 mm x 5 mm |

| Weight |

Around 0.15 kg |

- High – Precision Signal Conditioning: The DS200TBQEG1B can achieve an accuracy of up to ±0.05% for signal conditioning. This high level of precision ensures that the control system makes accurate decisions based on the sensor data, reducing the risk of equipment malfunction.

- Robustness and Reliability: With a Mean Time Between Failures (MTBF) of over 250,000 hours, the board is highly reliable. It is also equipped with advanced EMI shielding, which can reduce electromagnetic interference by up to 95%, allowing it to operate stably in electrically noisy environments.

- Flexible Configuration: The board features two field – configurable jumpers (BJ1, BJ2), which enable users to adapt the board to different system requirements. This flexibility simplifies system integration and customization.

- Compact Design: Its small form factor (170 mm x 90 mm x 5 mm) makes it suitable for installations where space is limited. Despite its compact size, it can handle a large number of signal connections.

- Power Generation: In gas and steam turbine power plants, the DS200TBQEG1B is used to monitor turbine shaft vibrations using Proximitor sensors. For example, in a large – scale gas power plant in Asia, the board was installed to interface with multiple Proximitor sensors. By accurately processing the vibration signals, the control system could detect early signs of turbine problems, enabling preventive maintenance and reducing downtime by 30%.

- Oil and Gas: In offshore oil platforms, the board is used to control valve actuators based on pressure and flow sensor data. A North American offshore platform used the DS200TBQEG1B to manage the flow of oil through pipelines. The accurate signal processing of the board ensured that the valves opened and closed at the right times, improving the overall efficiency of the oil extraction process by 20%.

- Industrial Automation: In manufacturing plants, it can be used to calibrate robotic arms using LVDT sensors. A European automotive manufacturing plant integrated the board into its robotic assembly line. By precisely measuring the position of the robotic arms, the board helped to improve the assembly accuracy, reducing product defects by 25%.

Compared to other analog termination boards in the market, the DS200TBQEG1B offers several significant advantages. Firstly, its high – precision signal conditioning with an accuracy of ±0.05% is superior to many competitors, which typically offer an accuracy of around ±0.1%. Secondly, its wide operating temperature range of – 40°C to +70°C is broader than that of most competing products, making it more suitable for use in extreme environments. Additionally, the board’s long MTBF and effective EMI shielding provide better reliability and stability compared to similar products.

- System Compatibility: Ensure that the DS200TBQEG1B is compatible with your existing GE Mark V or Mark VI control system. Check the input and output signal types, as well as the communication protocols, to ensure seamless integration.

- Environmental Conditions: Consider the operating environment where the board will be installed. If the environment has high levels of electromagnetic interference or extreme temperature variations, the board’s robust design makes it a good choice.

- Budget: While the DS200TBQEG1B offers high – end features and reliability, it is important to compare its cost with your budget. However, also take into account the long – term savings in terms of reduced maintenance and improved system performance.

- Installation: When installing the DS200TBQEG1B, use proper electrostatic discharge (ESD) protection measures to prevent damage to the components. Ensure that all connections are secure and that the board is properly grounded.

- Testing: Use calibrated instruments to verify the functionality of the test points (TP1, TP2, TP3). Regularly perform diagnostic tests to ensure that the board is operating correctly.

- Ribbon Cables: When disconnecting or reconnecting ribbon cables, grasp the connectors firmly to avoid damaging the wires. Do not pull on the cables themselves.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for

DS200TBQEG1B and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide