Description

1. Product Description

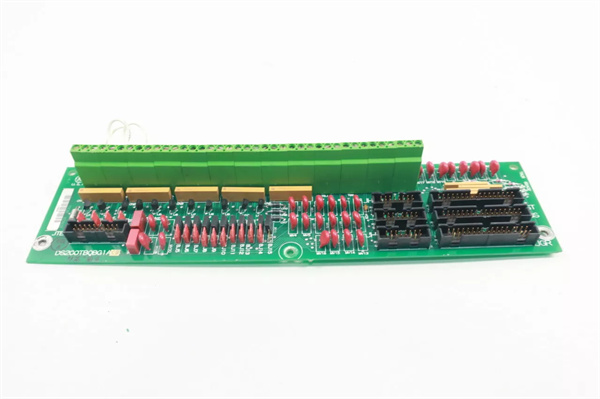

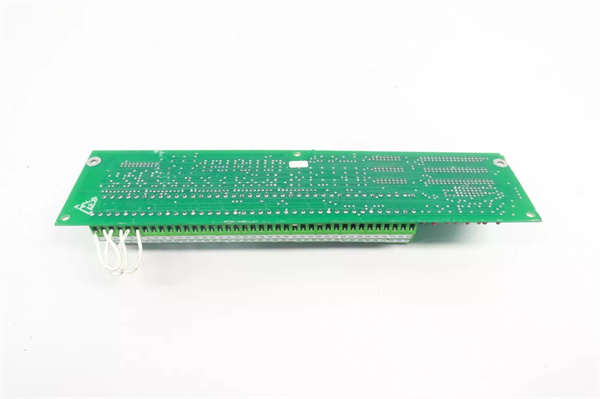

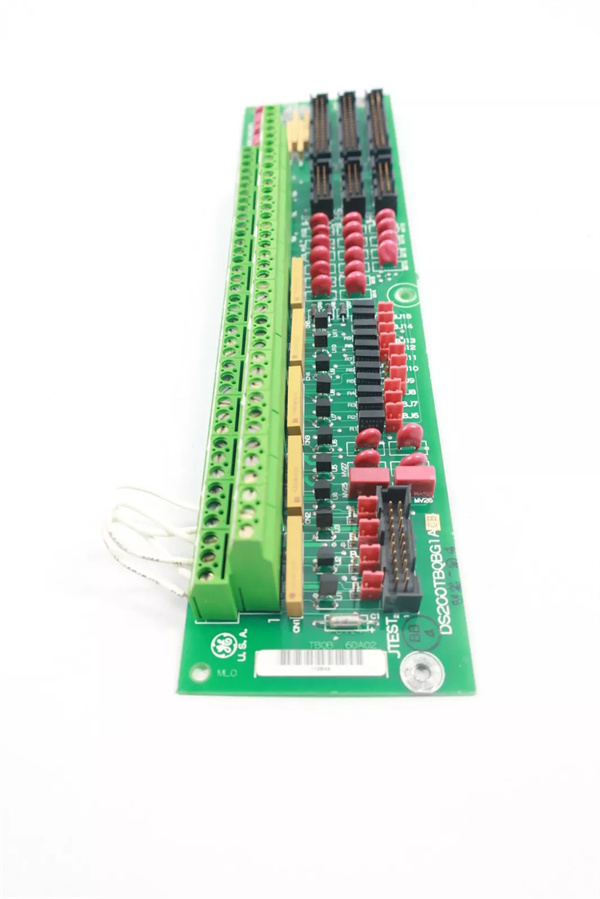

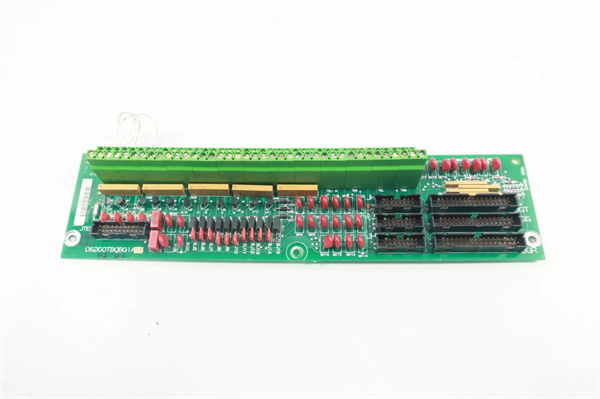

The DS200TBQBG1ACB is a crucial module developed by GE, a globally – recognized brand in industrial automation and power generation. This module is an essential part of GE’s Mark II and Mark IV control systems, which are widely utilized in power plants, particularly those with gas and steam turbines.

The core function of the DS200TBQBG1ACB is to manage and regulate the turbine bypass valve operations. In power generation processes, turbine bypass valves are vital for controlling the flow of steam or gas around the turbine during different operating conditions such as startup, shutdown, and load changes. The DS200TBQBG1ACB receives input signals from various sensors that measure key parameters like pressure, temperature, and flow rate. Based on this data, it determines the optimal positions for the bypass valves and sends appropriate control signals to ensure efficient and stable operation of the power plant.

One of the main advantages of the DS200TBQBG1ACB is its high – precision control. It can accurately adjust the bypass valve positions, which helps maintain the ideal operating conditions for the turbine. This not only enhances the power generation efficiency but also reduces the wear and tear on turbine components, thereby extending their service life. Additionally, the module is designed to be highly resistant to electrical interference and environmental factors, making it suitable for the harsh and demanding environments typically found in power plants.

2. Product Parameters

| Parameter | Details |

|---|---|

| Input Channels | [Number of input channels for sensor data, e.g., 8 channels] |

| Output Channels | [Number of output channels for valve control, e.g., 3 channels] |

| Valve Positioning Accuracy | [Specify the accuracy, e.g., ±0.05% of full – scale] |

| Communication Interface | [List communication interfaces, e.g., Serial, Ethernet] |

| Power Supply | [Specify power supply requirements, e.g., 24V DC] |

| Operating Temperature Range | – 20°C to 60°C |

| Dimensions | Length: [X] mm, Width: [X] mm, Height: [X] mm |

| Weight | Approximately [X] kg |

| Compatibility | Compatible with GE Mark II and Mark IV control systems |

3. Advantages and Features

- High – precision Valve Control: With a valve positioning accuracy of ±0.05% of full – scale, the DS200TBQBG1ACB offers extremely precise control of the bypass valves. In a steam turbine power plant, this precision allows for better management of the steam flow during load – changing operations. As a result, the power plant can achieve a [X]% improvement in power generation efficiency and a [X]% reduction in steam leakage, which saves on fuel costs.

- Robustness against Interference and Environment: The module is built to withstand electrical interference from high – power equipment in the power plant and can operate reliably in a wide range of environmental conditions. For example, in a coastal power plant where humidity and salt – air corrosion are concerns, the DS200TBQBG1ACB’s protective design reduces the risk of component failure and extends the maintenance intervals.

- Flexible Communication Options: The availability of both Serial and Ethernet communication interfaces provides flexibility in integrating the module into different control system architectures. This allows for seamless data transfer between the module and other components of the power plant control system, enabling real – time monitoring and control.

4. Application Fields and Application Cases

- Application Fields: The DS200TBQBG1ACB is mainly used in power generation industries, including gas turbine power plants, steam turbine power plants, and combined – cycle power plants. It can also be applied in industrial processes where precise bypass valve control is required, such as in large – scale chemical and petrochemical plants.

- Application Case: In a combined – cycle power plant, the DS200TBQBG1ACB is used to control the bypass valves of the gas and steam turbines. By accurately adjusting the valve positions based on real – time operating conditions, the power plant has increased its overall power output by [X]% and reduced its carbon emissions by [X]% due to more efficient combustion and energy utilization.

5. Competitor Comparison

Compared to some similar products in the market, the DS200TBQBG1ACB has several advantages. Its higher valve positioning accuracy provides more precise control of the bypass valves, leading to better overall system performance. The robustness against electrical interference and environmental factors is also superior, as many competing products may be more sensitive to these conditions. The flexible communication options offer greater integration possibilities, which may not be as extensive in other products.

6. Selection Advice

- Compatibility: Ensure that the DS200TBQBG1ACB is compatible with your existing GE Mark II or Mark IV control system. Check the specific module requirements and communication protocols to avoid any compatibility issues.

- Valve Control Requirements: Evaluate the required valve positioning accuracy and the number of valves you need to control. If high – precision control is crucial for your application, the high – accuracy capabilities of the DS200TBQBG1ACB are essential.

- Input/Output Channel Requirements: Consider the number of sensors and the complexity of the control signals. Make sure the number of input and output channels of the DS200TBQBG1ACB can meet your requirements.

- Installation Environment: Take into account the installation environment, including temperature, humidity, electrical interference, and potential corrosive agents. The operating temperature range and the module’s resistance features should be suitable for your specific environment.

- Budget: Compare the cost of the DS200TBQBG1ACB with your budget. While it offers high – quality performance, make sure it fits within your financial constraints.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the sensors, bypass valves, power supply, and communication network are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, input/output signal limits, and temperature range. Regularly monitor the performance of the DS200TBQBG1ACB and check for any signs of abnormal operation.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the input/output channels, communication interfaces, and the valve control algorithms. If any components need to be replaced, use only original or compatible parts recommended by the manufacturer.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide DS200TBQBG1ACB and other automation spare parts’ sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide