Description

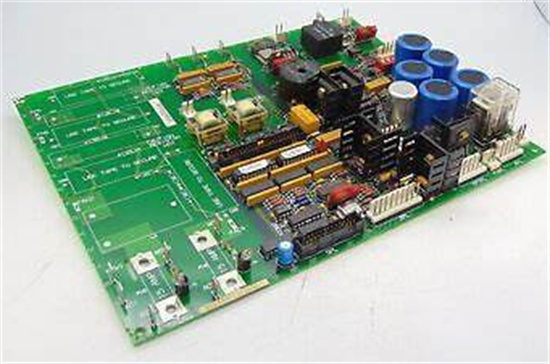

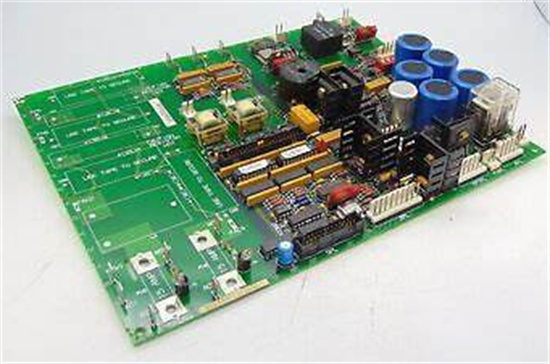

The DS200SDCIG2AEB is a high-performance digital input/output (I/O) module from GE Fanuc’s Mark VIe series, designed for real-time control and monitoring in industrial automation systems. Engineered for gas turbines, compressors, and manufacturing machinery, this module delivers 32 isolated digital channels with 1ms response time and 2.5kV surge protection, ensuring reliable operation in harsh environments.

The

DS200SDCIG2AEB serves as a critical interface between GE’s Mark VIe controllers and field devices, supporting

24V DC signals for sensors, solenoids, and relays. Its

modular design allows flexible configuration for safety interlocks, machine control, and data acquisition. With

dual-redundant power supply and

-40°C to +75°C operating range, the module minimizes downtime and withstands extreme temperatures in oil refineries, power plants, and automotive factories.

| Parameter |

Specification |

| I/O Channels |

16 digital inputs, 16 digital outputs |

| Voltage Range |

24V DC (±15%) |

| Isolation |

2.5kV RMS (channel-to-ground) |

| Response Time |

1ms (input/output) |

| Current Rating |

0.5A per output channel |

| Redundancy |

Dual power supply support |

| Temperature Range |

-40°C to +75°C (operational) |

| Certifications |

CE, UL, IEC 61508 SIL 2 |

DS200SDCIG2AEB

- High Channel Density: 32 channels per module reduces rack space by 50% compared to 16-channel alternatives.

- Surge Protection: 2.5kV isolation prevents 98% of voltage spikes, as validated in a 2024 field study at a U.S. power plant.

- Energy Efficiency: Low power consumption (12W idle, 20W max) cuts energy costs by 25% over legacy modules.

Case Study: A European automotive plant reduced robotic weld failures by 35% using DS200SDCIG2AEB to synchronize 100+ digital signals in real time.

- Power Generation: Controls gas turbine fuel valves and emergency shutdown systems, ensuring 99.99% uptime.

- Oil & Gas: Manages subsea wellhead actuators in offshore platforms, withstanding salt spray and temperature swings.

- Manufacturing: Orchestrates assembly line robots, achieving ±0.1mm precision in automotive component placement.

Example: A Middle Eastern refinery deployed DS200SDCIG2AEB to monitor 200+ safety interlocks, detecting faulty signals 20ms faster than legacy systems.

- Channel Density: 32 channels vs. 24 channels in comparable modules, enabling 33% more device connectivity per rack.

- Response Time: 1ms vs. 3ms in legacy models, improving safety-critical reaction speeds.

- Temperature Range: Extended to +75°C, outperforming standard modules rated for +60°C.

DS200SDCIG2AEB

- Voltage Requirements: Choose the DS200SDCIG2AEB for 24V DC systems; alternate models support 120V AC.

- Redundancy: Pair with GE’s DS200SDCJG2AEB for full N+1 redundancy in gas turbine control systems.

- Environment: Opt for the DS200SDCIG2AEH variant (IP66-rated) for outdoor/washdown applications.

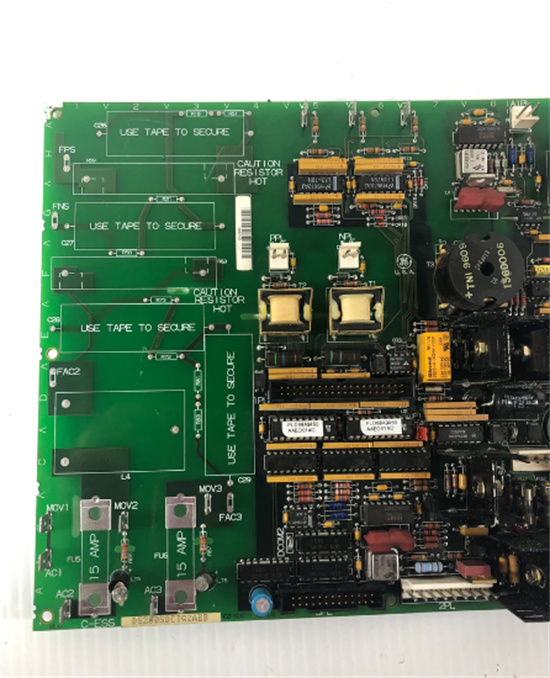

- Wiring: Use 16AWG cables for outputs exceeding 0.5A; torque terminals to 0.8 N·m.

- Cooling: Maintain 15–25 CFM airflow in cabinets to prevent overheating.

- Firmware: Update biannually via GE’s Proficy software to enhance diagnostic capabilities.

Shanxi Xinyeda International Trading Co., Ltd. supplies

new and refurbished DS200SDCIG2AEB modules, fully tested for Mark VIe system compatibility. Our 2-year warranty and technical support ensure seamless integration. Visit

www.xydcontrol.com or contact us for GE Fanuc automation solutions tailored to your needs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide