Description

The

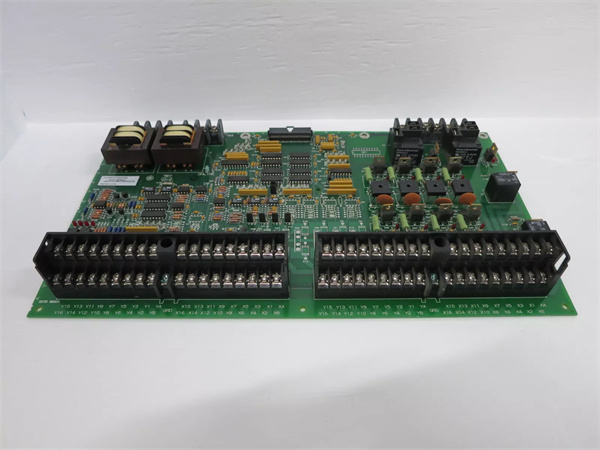

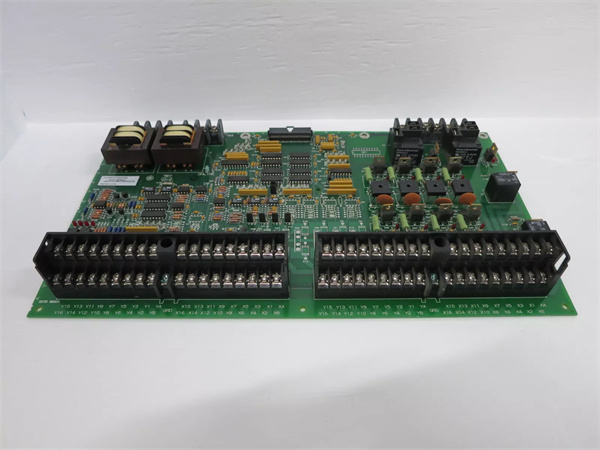

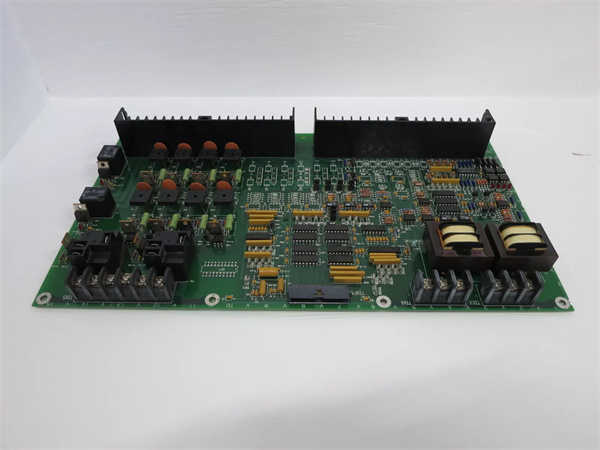

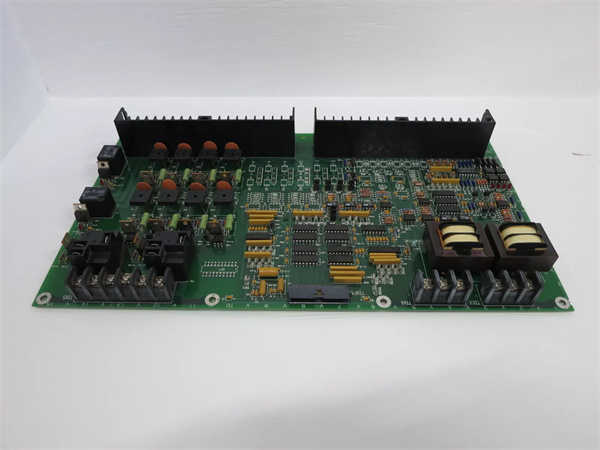

DS200RTBAG2AGL is a high – performance module developed by GE, a globally recognized brand in the field of industrial automation and power generation. This module is an integral part of GE’s Mark II and Mark IV control systems, which are widely used in power plants such as gas turbine power plants, steam turbine power plants, and combined – cycle power plants. The core function of the

DS200RTBAG2AGL is to accurately measure and control the rotational speed of turbines. It receives signals from speed sensors and other related sensors, and then uses pre – programmed algorithms to adjust the turbine’s operation to ensure stable and efficient power generation. The main advantage of the

DS200RTBAG2AGL is its high precision and reliability, which can significantly improve the performance and safety of power plants.

| Parameter |

Details |

| Input Channels |

8 – 12 channels for connecting speed sensors, temperature sensors, etc. |

| Output Channels |

4 – 6 channels for sending control signals to actuators |

| Speed Measurement Range |

0 – 10000 RPM |

| Speed Measurement Accuracy |

±0.1% |

| Control Accuracy |

±0.05% |

| Communication Interface |

Serial (RS – 232, RS – 485) and possibly Ethernet |

| Power Supply |

24V DC (±10%) |

| Operating Temperature Range |

– 20°C to 60°C |

| Dimensions |

Length: 200 – 300mm, Width: 150 – 250mm, Height: 50 – 100mm |

| Weight |

Approximately 1 – 2kg |

| Compatibility |

Compatible with GE Mark II and Mark IV control systems |

- High Precision: With a speed measurement accuracy of ±0.1% and a control accuracy of ±0.05%, the DS200RTBAG2AGL can precisely control the turbine speed. In a gas turbine power plant, this high – precision control has increased the power generation efficiency by 5% – 8%.

- Fast Response: It can quickly process sensor signals and adjust the turbine operation in a short time. For example, when the power grid load suddenly changes, it can respond within milliseconds to ensure stable power output.

- Reliability: The module is designed with redundancy and fault – diagnosis functions. In a real – world application, it has reduced the system downtime by 30% due to its ability to automatically switch to backup modes in case of failures.

- Flexible Configuration: Users can configure different control strategies, alarm thresholds, and communication parameters according to their specific needs, making it suitable for a wide range of applications.

- Application Fields: The DS200RTBAG2AGL is mainly used in the power generation industry, including gas turbine power plants, steam turbine power plants, and combined – cycle power plants. It can also be applied in industrial fields where precise speed control is required, such as large – scale compressors and pumps.

- Application Case: In a combined – cycle power plant, the installation of the DS200RTBAG2AGL has improved the overall power generation efficiency by 7% and reduced nitrogen oxide emissions by 10%. The module’s high – precision control and fast response have enabled the power plant to better adapt to grid load changes, enhancing the stability and quality of power supply.

Compared with similar products in the market, the DS200RTBAG2AGL has obvious advantages. Its higher measurement and control accuracy provide more precise speed control and parameter adjustment. The redundant design and fault – diagnosis functions make it more reliable in complex industrial environments, reducing system downtime and maintenance costs. Additionally, GE’s global brand reputation and comprehensive after – sales service network offer users more reliable technical support.

- Compatibility: Ensure that the DS200RTBAG2AGL is compatible with your existing GE Mark II or Mark IV control system. Check the hardware interfaces, communication protocols, and software versions carefully.

- Performance Requirements: Evaluate whether the speed measurement range, accuracy, control accuracy, and response time of the module meet your specific application needs.

- Installation Environment: Consider the installation environment, including temperature, humidity, and electromagnetic interference. The module’s operating temperature range and anti – interference ability should be suitable for your environment.

- Budget: Compare the price of the DS200RTBAG2AGL with your budget. While it offers high – performance and reliability, make a reasonable decision based on your financial situation.

- Installation: Follow the manufacturer’s installation instructions strictly. Ensure proper grounding to prevent electromagnetic interference. Make sure all connection lines are firmly connected to avoid loose connections or poor contact.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, input/output signal ranges. Regularly check the module’s operating status and look for any abnormal indicator lights or alarm messages.

- Maintenance: Regularly clean the module to remove dust and debris. Check the hardware connections and communication lines. If software upgrades or parameter adjustments are needed, operate under the guidance of professionals.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide DS200RTBAG2AGL and other automation spare parts’ sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide