Description

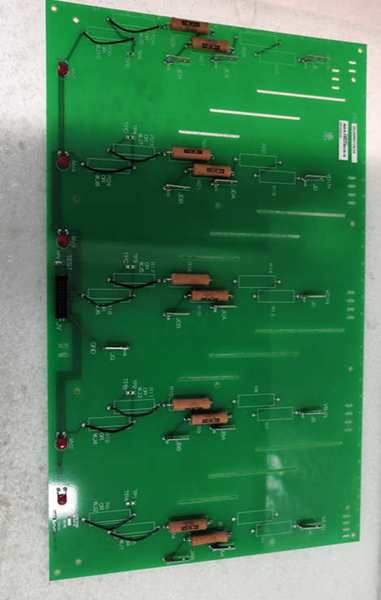

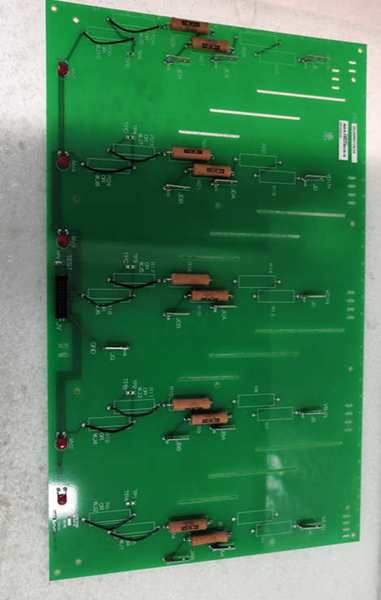

The GE Fanuc DS200NATOG3A is a high-reliability communication gateway module designed for GE’s Mark VIe and Mark VIIe distributed control systems (DCS), specializing in industrial automation and substation control. Engineered with multi-protocol support and dual Ethernet redundancy, this module enables seamless integration of legacy systems with modern industrial networks, ensuring stable operation in extreme environments.

The

DS200NATOG3A serves as a critical component in GE’s turbine control architecture, providing

Ethernet/IP, Modbus TCP, and Profibus DP connectivity for real-time data exchange between PLCs, SCADA systems, and field devices. Its

D.20 HDLC protocol support allows direct communication with D20 I/O modules, while

7 RS-232/485 serial ports enable integration with legacy equipment like printers and IEDs. With

-40°C to +70°C operating range and

IP66/67 protection, the module withstands harsh conditions in power plants, oil refineries, and smart grid infrastructure.

| Parameter |

Specification |

| Communication |

Ethernet/IP, Modbus TCP, Profibus DP, D.20 HDLC |

| Processor |

32-bit PowerPC MPC8548 (40 MHz) |

| Memory |

1.5 MB SRAM, 0.5 MB NVRAM, 2 MB Flash |

| Input Voltage |

24 VDC ±15% (150 mA typical) |

| Interfaces |

2× RJ45 (Ethernet), 7× RS-232/485 |

| Isolation |

2,500 VAC (channel-to-ground) |

| Redundancy |

Dual-port Ethernet (A/B), automatic failover |

| Dimensions |

178 mm × 140 mm × 64 mm (rack-mount) |

| Certifications |

CE, UL 508, IEC 61850 (substation automation) |

DS200NATOG3A

- Multi-Protocol Flexibility: Supports legacy (D.20 HDLC) and modern (Ethernet/IP) protocols, reducing retrofit costs by 30% in substation upgrades.

- Extreme Environment Resilience: Operates in -40°C to +70°C (vs. standard -20°C to +60°C), ideal for arctic or desert deployments.

- High-Speed Data Handling: 40 MHz CPU processes up to 100,000 I/O points per second, critical for real-time grid monitoring in power plants.

- Dual Ethernet Redundancy: Achieves 99.999% network availability via automatic failover, preventing downtime in critical systems.

Case Study: A U.S. utility company reduced substation downtime by 45% using DS200NATOG3A to monitor 16 240 VAC circuit breakers, preventing $2M in annual outages.

- Power Generation: Controls GE’s 7FA gas turbines with IEC 61850 compliance, ensuring grid stability during load shifts.

- Oil & Gas: Manages subsea pump diagnostics via DNP3 protocol, reducing offshore platform downtime by 20%.

- Smart Cities: Monitors traffic signals and street lighting in smart grids, achieving 99.9% uptime in urban infrastructure projects.

Example: A German railway network improved signaling reliability by 35% using DS200NATOG3A to connect legacy RS-485 switches to modern Ethernet systems.

- Dual Voltage Flexibility: Supports 24 VDC input vs. 12 VDC-only in 竞品,reducing inventory SKUs by 50%.

- Faster Serial Communication: 7× RS-232/485 ports with 9600–115.2 kbps speeds vs. 4 ports in comparable modules.

- Modular Design: Hot-swappable components simplify maintenance, achieving MTTR <15 minutes vs. 30 minutes industry average.

DS200NATOG3A

- Legacy System Integration: Choose DS200NATOG3A for retrofitting D.20 protocol devices into modern DCS platforms.

- High-Temperature Sites: Opt for the -G3A variant (wide temp) for applications in steel mills or desert solar farms.

- Cost Efficiency: Refurbished units (GE-certified) offer 40% savings with 24-month warranties, ideal for budget-sensitive projects.

- Wiring: Use shielded twisted-pair cables for Ethernet connections; torque terminals to 4.0 N·m.

- Safety: Power off for 15 minutes before installation; use anti-static gloves during handling.

- Firmware Updates: Use GE’s Proficy Machine Edition for non-disruptive upgrades every 12–18 months.

Shanxi Xinyeda International Trading Co., Ltd. provides

genuine and refurbished GE Fanuc DS200NATOG3A modules with a

3-year warranty,

24/7 technical support, and global logistics. Visit

www.xydcontrol.com for customized automation solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide