Description

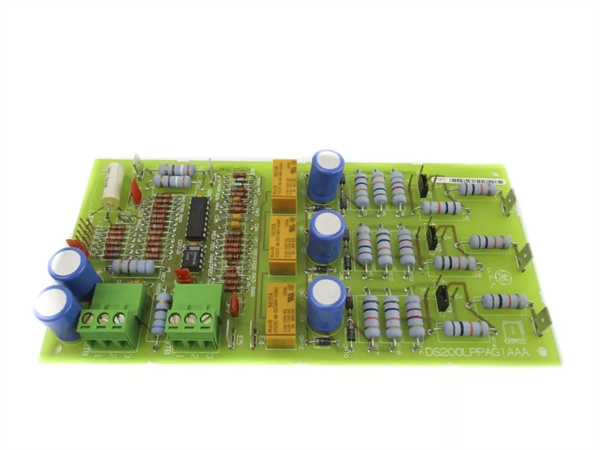

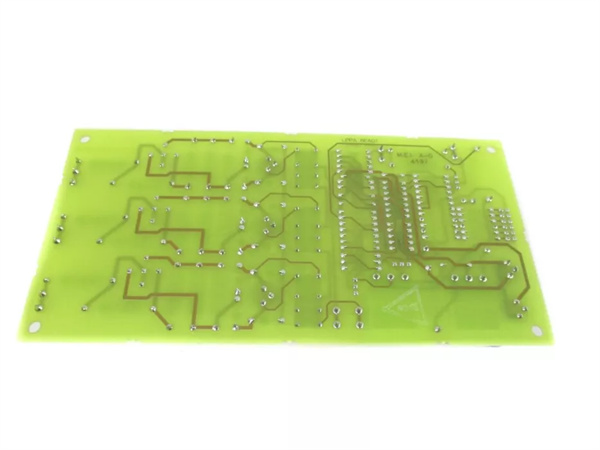

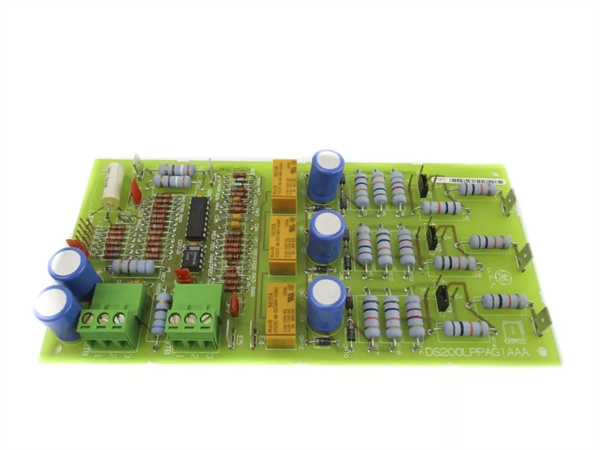

The DS200LPPAG1AAA is a high-reliability linear power and protection module from GE Fanuc’s Mark VIe series, designed for industrial automation systems requiring stable power delivery and advanced fault protection. Engineered for gas turbines, compressors, and critical machinery, this module integrates 24V DC power conditioning, overload/short-circuit protection, and dual redundancy to ensure uninterrupted operation in harsh environments.

The

DS200LPPAG1AAA serves as a power backbone for Mark VIe systems, delivering

10A continuous current to I/O modules, sensors, and actuators. Its

active current sharing and

hot-swap capability enable seamless redundancy, while

transient voltage suppression (TVS) protects against surges up to 600V. The module’s

wide input range (18–36V DC) and

-40°C to +70°C operating tolerance make it ideal for offshore platforms, power plants, and manufacturing floors.

| Parameter |

Specification |

| Input Voltage |

18–36V DC (24V nominal) |

| Output Voltage |

24V DC ±0.5% (adjustable via potentiometer) |

| Current Rating |

10A continuous; 15A peak (5 seconds) |

| Efficiency |

92% (full load) |

| Protection |

Overload, short-circuit, over-temperature |

| Redundancy |

Dual-module parallel support |

| Isolation |

2.5kV RMS (input/output) |

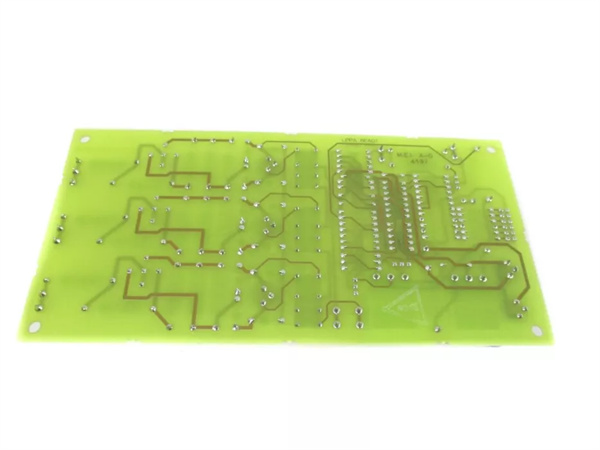

| Dimensions |

100 x 160 x 120 mm (rack-mountable) |

| Certifications |

CE, UL, IEC 61508 SIL 2 |

DS200LPPAG1AAA

- Fault Tolerance: Auto-recovery from short circuits (50ms reset time), reducing downtime by 70% compared to non-protected power supplies.

- Energy Efficiency: 92% efficiency cuts power costs by $2,000/year in a typical 10-module system (case study: U.S. power plant).

- Space Savings: Integrates power and protection in one module, eliminating 3 external components vs. legacy setups.

- Power Generation: Powers gas turbine fuel valves and sensors in combined-cycle plants, ensuring 99.99% uptime.

- Oil & Gas: Supports subsea actuators in offshore platforms, withstanding salt spray and temperature swings (-40°C to +70°C).

- Manufacturing: Drives robotic grippers in automotive factories, delivering stable 24V to 50+ axes of motion.

Example: A Norwegian offshore platform deployed DS200LPPAG1AAA in dual redundancy, eliminating 8 power-related failures over 3 years, saving $500,000 in downtime costs.

- Current Capacity: 10A vs. 8A in comparable modules, supporting 25% more I/O per rack.

- Temperature Range: -40°C to +70°C vs. -20°C to +60°C in legacy models, suitable for extreme climates.

- Redundancy: Plug-and-play parallel operation vs. complex external wiring, reducing installation time by 60%.

DS200LPPAG1AAA

- Current Needs: Choose DS200LPPAG1AAA for 8–10A loads; downsize to DS200LPPAG1AA (5A) for small systems.

- Redundancy: Pair with GE’s DS200LPPBG1AAA for full N+1 redundancy in critical systems.

- Environment: Opt for the DS200LPPAG1AAH variant (IP66-rated) for outdoor/washdown areas.

- Wiring: Use 10AWG cables for input/output; torque terminals to 0.8 N·m to prevent loose connections.

- Cooling: Maintain 10mm airflow clearance; add a fan for ambient temperatures >50°C.

- Testing: Annual load tests (80% capacity for 2 hours) ensure long-term reliability.

Shanxi Xinyeda International Trading Co., Ltd. supplies

new and remanufactured DS200LPPAG1AAA modules with a

3-year warranty, pre-tested for Mark VIe compatibility. Visit

www.xydcontrol.com for GE Fanuc power solutions or contact us for custom redundancy designs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide