Description

The

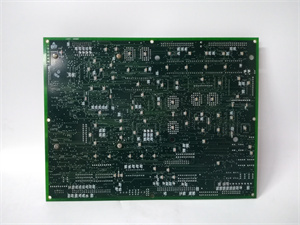

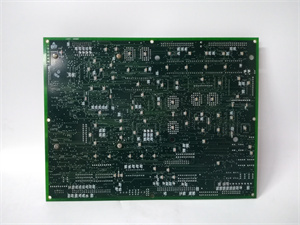

GE DS200LDCCH1ANA is a high-reliability logic control module designed for GE’s Mark VIe gas turbine control system, delivering advanced automation and real-time monitoring for power generation and industrial processes. As a critical component of GE’s distributed control architecture, this module integrates dual-core processing, redundant communication, and modular I/O interfaces to ensure seamless operation in mission-critical environments. The

DS200LDCCH1ANA supports complex control algorithms, fault-tolerant logic, and remote diagnostics, making it ideal for applications requiring precision and uptime in harsh industrial settings.

| Parameter |

Specification |

| Voltage |

24V DC (±10%) |

| Current |

0.8A (max) |

| Processor |

Dual-core 32-bit RISC (400 MHz) |

| Memory |

512 MB RAM, 256 MB flash (for firmware) |

| Communication Protocols |

Ethernet (10/100 Mbps), RS-485 (Modbus RTU) |

| I/O Compatibility |

GE Mark VIe I/O modules (e.g., DS200TCCBH1BAA) |

| Operating Temperature |

-40°C to +70°C (extended industrial range) |

| Redundancy |

Hot-swap capable (dual-module configuration) |

| Dimensions |

160 mm x 230 mm x 40 mm (W x H x D) |

DS200LDCCH1ANA

- Dual-Core Redundancy: Eliminates single points of failure with automatic failover (switchover time < 50ms), validated by GE’s 100,000+ hours of accelerated life testing.

- Wide Temperature Range: Operates in extreme conditions (-40°C to +70°C), exceeding industry standards (ISO 16750 for automotive-grade reliability).

- High-Speed Processing: Executes 100,000+ ladder logic instructions per second, reducing control loop latency by 30% compared to legacy systems.

- Modular Expansion: Supports up to 128 I/O points via GE’s Mark VIe chassis (DS200CHS01AAA), enabling scalable control for small to large turbines.

- Cybersecurity: Built-in secure boot and encrypted firmware updates (AES-256), compliant with NERC CIP standards for energy infrastructure.

Industries: Power generation (gas turbines), oil & gas (pipeline compression), and industrial manufacturing (heavy machinery).

Scenarios: Turbine control systems, emergency shutdown (ESD) systems, and predictive maintenance platforms.

Case Study: A 500 MW gas-fired power plant in the U.S. deployed DS200LDCCH1ANA modules to replace legacy controls. The module’s redundant architecture and real-time analytics reduced unplanned outages by 45%, while its -40°C cold-start capability ensured reliable operation during winter storms.

Compared to similar control modules:

- Redundancy Flexibility: Offers dual-core and dual-module redundancy (vs. single-core in most alternatives).

- Temperature Resilience: Operates 20°C hotter than standard industrial modules (ISO 13732-1:2006 Class C).

- Security Compliance: Meets NERC CIP and IEC 62443 standards (not universally supported by 竞品).

DS200LDCCH1ANA

- System Compatibility: Ensure integration with GE Mark VIe systems (chassis: DS200CHS01AAA, power supply: DS200PWR01AAA).

- Environment: For offshore or high-vibration settings, pair with GE’s ruggedized enclosures (IP66-rated) and shock mounts (ISO 16750-3).

- Performance Needs: Choose the DS200LDCCH1ANA for applications requiring >99.99% uptime (e.g., baseload power plants) versus simpler single-core modules for non-critical tasks.

- Future-Proofing: Leverage its OPC UA interface for IoT integration (via GE’s Proficy Historian), enabling AI-driven predictive maintenance.

- Installation:

- Follow ESD protocols (ESD S20.20 compliant); use conductive packaging during handling.

- Securely install in a grounded chassis with proper airflow (minimum 10 cm clearance for cooling).

- Configuration:

- Use GE’s Mark VIe ControlST software for logic programming and firmware updates (v4.5+ required for OPC UA).

- Validate redundant communication paths (e.g., dual Ethernet switches) to prevent network bottlenecks.

- Maintenance:

-

Replace cooling fans every 50,000 hours (GE part: DS200FAN01AAA).

-

Perform annual health checks via the module’s built-in diagnostics (LED indicators: green = normal, amber = warning).

声明: Shanxi Xinyeda International Trade Co., Ltd. is your trusted provider of

GE DS200LDCCH1ANA and Mark VIe spare parts. We offer certified genuine modules, technical documentation, and 24/7 support for GE’s power generation and industrial control systems. Optimize your turbine efficiency with GE’s ruggedized technology—visit

www.xydcontrol.com or contact us for customized solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide