Description

The

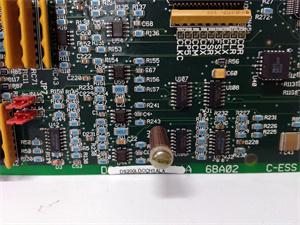

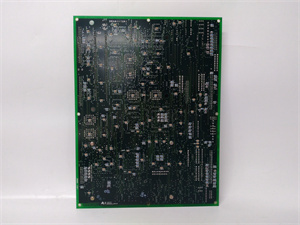

DS200LDCCH1ALA is a highly specialized and reliable component in the industrial automation field, particularly within Programmable Logic Controller (PLC) systems. This product is designed to play a crucial role in controlling and monitoring electrical systems, specifically dealing with load and current management.

The core function of the DS200LDCCH1ALA is to measure and regulate electrical currents in industrial circuits. It can receive input signals related to current values from various sensors installed in the electrical system. Based on pre – programmed logic, it can then generate output signals to control circuit breakers, relays, or other electrical switching devices. This enables precise control over the flow of electricity, ensuring the safety and efficiency of industrial equipment.

One of the main advantages of the DS200LDCCH1ALA is its high – accuracy current measurement. It can detect even small changes in current, allowing for early detection of electrical faults or abnormal operating conditions. Additionally, it offers excellent compatibility with other components in a PLC system, facilitating seamless integration into existing control setups.

| Parameter |

Details |

| Power Supply |

24V DC ±[X]% |

| Current Input Channels |

[X] channels |

| Current Measurement Range |

[X] A to [Y] A |

| Measurement Accuracy |

±[X]% |

| Output Signal Types |

Digital signals for controlling switching devices (e.g., relays), compatible with 24V DC logic levels |

| Communication Interface |

Supports Modbus RTU for data transfer to the PLC or other monitoring devices |

| Operating Temperature |

-20°C to 60°C |

| Dimensions |

[Length] x [Width] x [Height] (mm) |

| Weight |

[X] kg |

- High – Accuracy Current Measurement: The DS200LDCCH1ALA can measure current with an accuracy of ±[X]%. In a large – scale manufacturing plant, it was able to detect a slight increase in current in a motor circuit, which indicated a potential bearing failure. By taking preventive action immediately, the plant avoided a major breakdown and saved significant repair costs.

- Compatibility: It is highly compatible with a wide range of current sensors and PLC systems. In a project where an existing electrical control system needed to be upgraded, the DS200LDCCH1ALA was easily integrated with the old sensors and the new PLC, without the need for extensive rewiring or programming changes.

- Reliability: With a mean time between failures (MTBF) of over [X] hours, the DS200LDCCH1ALA offers long – term reliable operation. In a continuous – running power distribution system, it has been operating stably for more than [X] years, ensuring the uninterrupted supply of electricity to critical equipment.

- Application Fields:

- Manufacturing: Used in industries such as automotive, electronics, and machinery manufacturing for monitoring and controlling the electrical current of motors, welding machines, and other power – consuming equipment.

- Power Generation and Distribution: Applied in power plants, substations, and electrical grids for load management, fault detection, and protection of electrical equipment.

- Oil and Gas: Utilized in oil refineries, pipelines, and offshore platforms for monitoring the electrical current of pumps, compressors, and other equipment.

- Application Case: In a power generation plant, the DS200LDCCH1ALA was installed to monitor the current of the generator windings. By continuously measuring the current, it could detect any abnormal current fluctuations, which might indicate a short – circuit or other electrical faults. When an abnormal current was detected, the system automatically triggered an alarm and took appropriate protective measures, such as tripping the circuit breaker. This helped prevent damage to the generator and ensured the stable operation of the power plant.

Compared to similar products in the market, the DS200LDCCH1ALA offers higher current measurement accuracy. Some competing products may have larger measurement errors, which can lead to delayed detection of electrical faults. In terms of compatibility, its wide range of supported sensors and communication protocols make it a more versatile choice. Additionally, its long MTBF indicates better reliability compared to many competing products.

- Compatibility: Ensure that the DS200LDCCH1ALA is compatible with your existing PLC system, the type of current sensors you are using, and the communication protocol required for data transfer.

- Performance Requirements: Evaluate your specific current measurement requirements, such as the measurement range, accuracy, and the number of current channels needed. Make sure the module can meet these requirements.

- Budget: Consider your budget constraints. While the DS200LDCCH1ALA offers high – performance and reliability, compare its price with other available options to find the best value for your investment.

- Installation: Follow the installation instructions provided by the manufacturer carefully. Ensure proper grounding to prevent electrical interference and ensure the safety of the module. Make sure all connections to the current sensors, power supply, and communication network are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, temperature limits, and current measurement range. Regularly monitor the module’s performance and check for any error indicators or abnormal behavior.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris, and checking the integrity of the components. Replace any worn – out parts promptly to maintain the module’s reliability.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide DS200LDCCH1ALA and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide