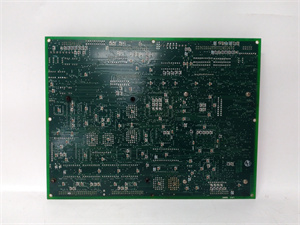

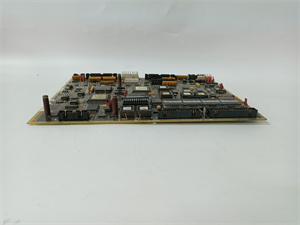

Description

1. Product Overview

The DS200LDCCH1AGA is a component commonly used in industrial automation systems, particularly in the context of Programmable Logic Controller (PLC) setups. It likely serves as a specific type of I/O (Input/Output) module, facilitating the interaction between the PLC and external devices in an industrial process.

2. Functionality

- Digital Input Handling: This module can receive digital signals from various field devices such as limit switches, proximity sensors, and push – buttons. These signals represent the status of different components in the industrial environment, like whether a machine is running, a door is open or closed, or a conveyor belt has reached a certain position. The module then converts these physical on – off states into digital values that the PLC can process.

- Digital Output Control: Based on the control decisions made by the PLC’s central processing unit, the DS200LDCCH1AGA can send digital control signals to actuators. These actuators can include relays, solenoid valves, and indicator lights. For example, it can control the opening and closing of a solenoid valve to regulate the flow of a liquid or gas in a pipeline.

- Communication with PLC: It communicates with the PLC using a specific communication protocol. This allows for seamless data transfer between the I/O module and the PLC, enabling the PLC to monitor the status of the industrial process and issue appropriate control commands.

3. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | 24V DC ±[X]% (a common tolerance value [X] is around 10% to account for normal voltage fluctuations in the industrial power supply). This voltage provides the necessary energy for the module’s operation. |

| Digital Input Channels | [X] channels (a typical number could be 8, 16, or 32). The number of input channels determines how many external digital devices can be connected to the module simultaneously. |

| Digital Output Channels | [Y] channels. Similar to the input channels, the number of output channels dictates the number of actuators that the module can control. Each output channel usually has a specific current – carrying capacity, for example, [Z] mA, which is sufficient to drive common industrial relays and solenoids. |

| Input Signal Voltage Range | 0 – 24V DC. This range is compatible with the output signals of most standard industrial digital sensors. |

| Output Signal Voltage and Current | Outputs are typically 24V DC with a defined current rating per channel. This allows for reliable control of the connected actuators. |

| Communication Interface | Supports a well – known industrial communication protocol, such as Modbus RTU or Ethernet/IP. This enables easy integration with the PLC and other devices in the industrial network. |

| Operating Temperature | -20°C to 60°C. This wide temperature range ensures that the module can operate reliably in different industrial environments, from cold storage facilities to hot manufacturing plants. |

| Dimensions | [Length] x [Width] x [Height] (mm). The compact form factor is designed for easy installation in control cabinets or other industrial enclosures. |

| Weight | [X] kg |

4. Advantages

- Reliability: Built with high – quality components, the DS200LDCCH1AGA has a long mean time between failures (MTBF). In continuous – running industrial processes, such as a 24/7 manufacturing line, its reliability ensures minimal downtime and reduced maintenance costs.

- Flexibility: With a configurable number of input and output channels, it can be adapted to different industrial applications. For example, in a small – scale automation project, a module with fewer channels may be sufficient, while a large – scale production line may require a module with more channels.

- Compatibility: It is designed to be compatible with a wide range of PLC systems. This makes it easy to integrate into existing industrial control systems without the need for major modifications.

5. Application Fields

- Manufacturing: In automotive, electronics, and machinery manufacturing, it can be used for machine control, production line monitoring, and quality control. For instance, in an automotive assembly line, it can monitor the position of robotic arms and control the operation of conveyor belts.

- Energy Sector: In power generation, distribution, and renewable energy systems, it can monitor the status of electrical switches, circuit breakers, and other control devices. It can also control the operation of small – scale motors and solenoids in power equipment.

- Water Treatment: In water treatment plants, it can be used to control the operation of pumps, valves, and level sensors. For example, it can detect the water level in a tank using a level sensor and then control the pump to fill or empty the tank accordingly.

6. Selection Considerations

- Compatibility: Ensure that the DS200LDCCH1AGA is compatible with your existing PLC system in terms of communication protocol, power supply, and physical mounting.

- I/O Requirements: Evaluate your specific needs for the number of digital input and output channels. Consider the types of external devices you will be connecting to the module and their signal requirements.

- Budget: Compare the cost of the DS200LDCCH1AGA with other similar digital I/O modules in the market. Consider the long – term benefits of reliability and performance when making a decision.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, input devices, output actuators, and communication network are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, temperature limits, and input/output current ratings. Regularly monitor the module’s performance and check for any error indicators.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the components and replace any worn – out parts promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer the DS200LDCCH1AGA and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide