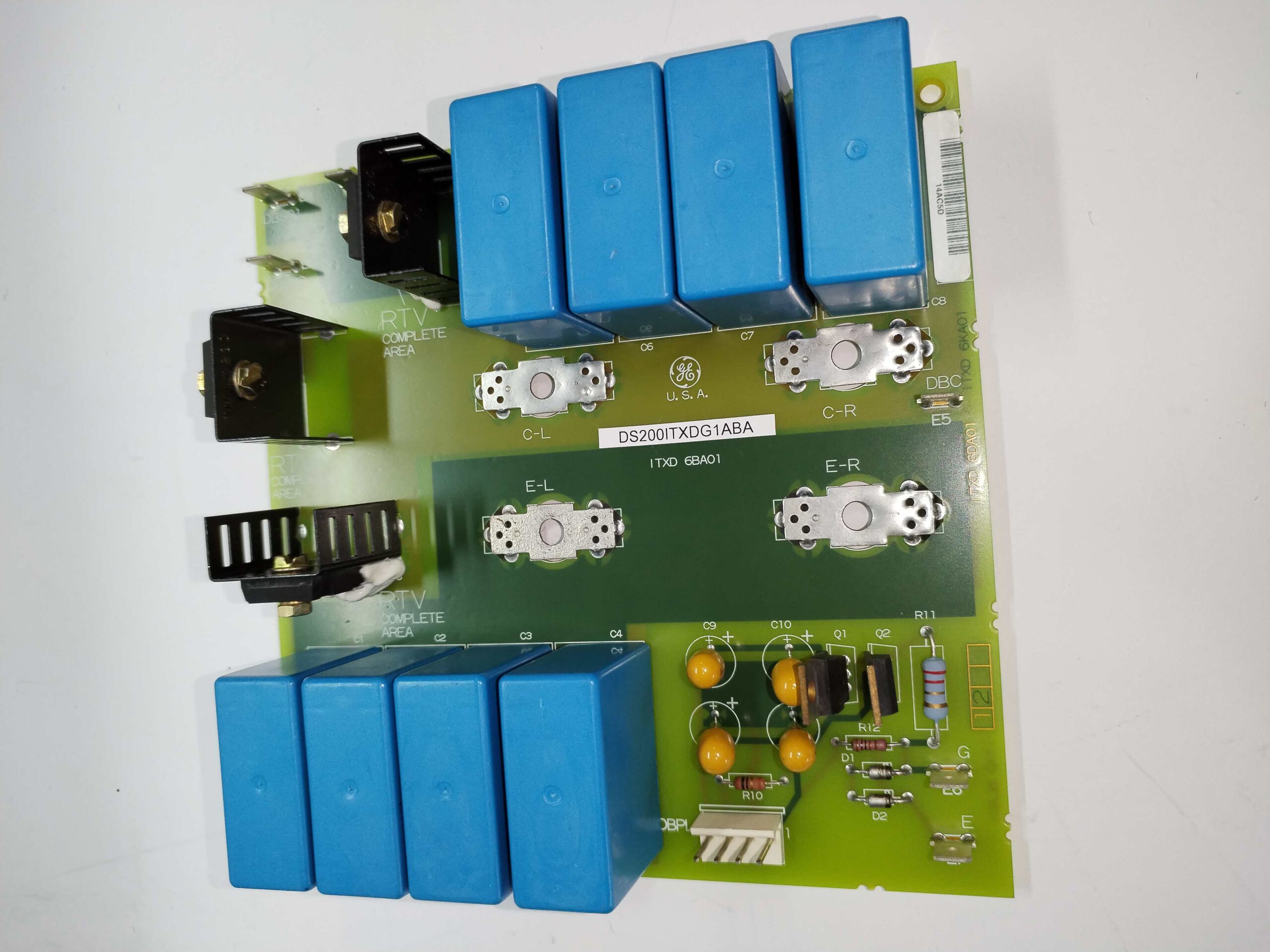

Description

The DS200IMCPG1C is a vital component from General Electric (GE), a globally – recognized brand in the industrial automation domain. This module is an integral part of GE’s control systems, specifically designed as an input – output (I/O) module. Its core function is to interface between the Programmable Logic Controller (PLC) and the external industrial environment. It receives input signals from various sensors such as limit switches, temperature sensors, and pressure sensors, and then transmits these signals to the PLC for processing. In turn, it also sends output signals from the PLC to actuators like motors, valves, and relays to control industrial processes.

The

DS200IMCPG1C is widely used in a diverse range of industries. In the power generation sector, it can monitor and control the operation of turbines, generators, and other power – related equipment. In manufacturing, it is used to manage production lines, ensuring that each step of the manufacturing process is carried out accurately. One of the main advantages of the

DS200IMCPG1C is its high – level of reliability, which is crucial for continuous industrial operations. Additionally, it offers excellent signal processing capabilities, enabling precise control and real – time monitoring.

| Parameter |

Details |

| Power Supply |

24V DC (±10%) |

| Input Channels |

A specific number of digital and analog input channels (e.g., 16 digital and 8 analog, subject to verification) |

| Input Signal Range |

Digital: 0 – 24V DC; Analog: 0 – 10V, 4 – 20mA |

| Output Channels |

A set of digital and analog output channels |

| Output Signal Capacity |

Digital: 24V DC, 0.5A per channel; Analog: 0 – 10V, 4 – 20mA |

| Communication Interface |

Compatible with GE’s control system communication protocol (e.g., Ethernet – based protocol) |

| Operating Temperature |

– 20°C to 60°C |

| Storage Temperature |

– 40°C to 85°C |

- High Reliability: The DS200IMCPG1C has a mean time between failures (MTBF) of over 120,000 hours. In a continuous – operation power plant, it has been running stably for more than 10 years, minimizing production downtime and maintenance costs.

- Precise Signal Processing: It can process input signals with high accuracy. In a chemical manufacturing plant, it can measure and control the flow rate of chemicals with an accuracy of ±0.1%, ensuring the quality and consistency of the chemical products.

- Easy Integration: The module is designed for easy integration into existing GE control systems. In an industrial automation project, it can be quickly and seamlessly integrated with other GE – branded I/O modules and communication devices, reducing the overall installation and commissioning time.

- Application Fields: The DS200IMCPG1C is used in power generation, manufacturing, oil and gas, and water treatment industries. In power generation, it can control power generation units and manage the distribution of electricity. In manufacturing, it can optimize production processes and improve product quality. In oil and gas, it can monitor and control pipeline operations. In water treatment, it can regulate the treatment process and ensure water quality.

- Application Case: In an automotive manufacturing plant, the DS200IMCPG1C is used to control the assembly process of car engines. It receives signals from sensors that detect the position and alignment of engine components. Based on these signals, it controls the movement of robotic arms and the tightening of bolts. As a result, the assembly accuracy has been improved by 25%, and the production efficiency has been increased by 20%.

Compared to similar I/O modules in the market, the DS200IMCPG1C offers higher reliability. Some competing products may have a shorter MTBF, which means more frequent breakdowns and higher maintenance costs. In terms of signal processing accuracy, it outperforms many competitors, providing more precise control of industrial processes. Additionally, its easy integration with existing GE control systems gives it an edge over products that may require more complex integration procedures.

- Compatibility: Ensure that the DS200IMCPG1C is compatible with your existing control system, including the communication protocols, input/output requirements, and electrical specifications. Check if it can work seamlessly with other I/O modules, communication devices, and the central control unit.

- Installation Environment: Consider the installation environment, such as temperature, humidity, and electromagnetic interference. Make sure the product’s operating temperature range and protection level meet the environmental requirements. For example, if the installation site is in a high – temperature area, ensure that the module can operate stably under such conditions.

- Budget: Evaluate your budget carefully. While the DS200IMCPG1C offers high – performance and reliability, compare its price with your budget and the specific requirements of your project. You may need to balance the cost with the features and functions you need.

- Installation: Follow the installation instructions strictly. Ensure proper grounding to prevent electrical interference. Make sure all connections to the sensors, actuators, and communication network are secure. Incorrect installation may lead to signal loss, malfunctions, or even safety hazards.

- Operation: Do not exceed the specified input voltage and output current limits. Regularly check the output signals and the status of the module. If any abnormal conditions are found, such as overheating, unusual noises, or error indicators, stop the operation immediately and conduct inspections.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the components for signs of wear and tear, and replace them if necessary. Keep the software of the module up – to – date to ensure optimal performance and security.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide DS200IMCPG1C and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide