Description

The

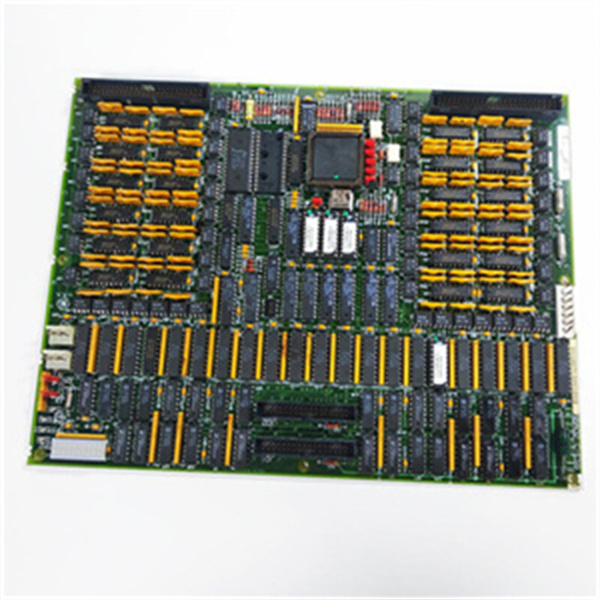

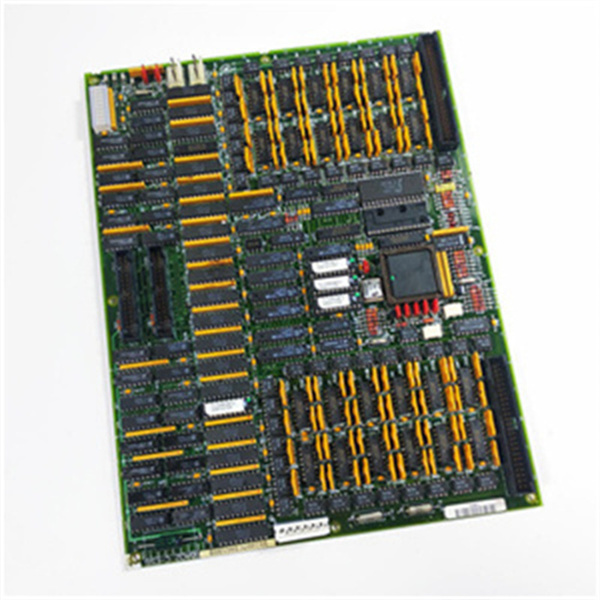

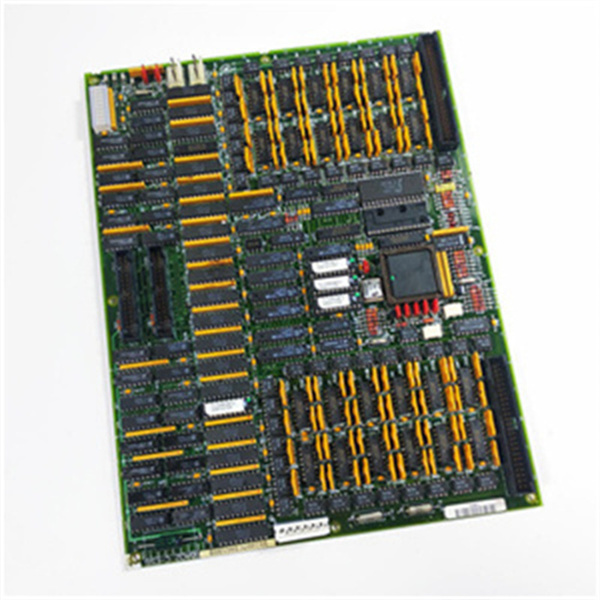

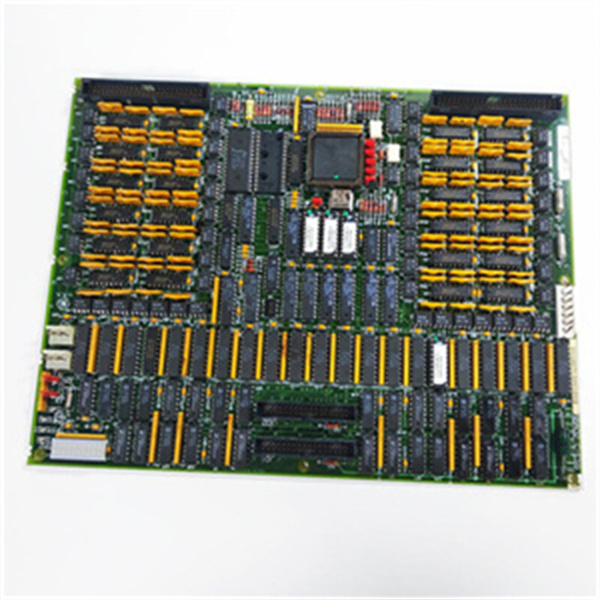

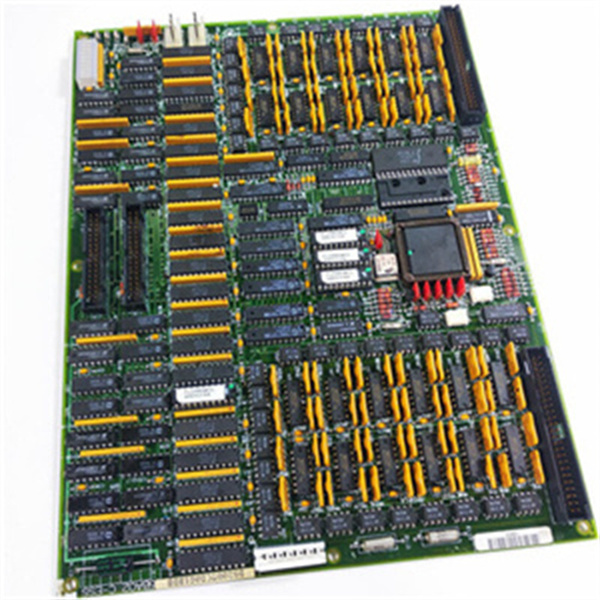

DS200GLAAG1A is a product from Westinghouse, a well – established brand in the industrial automation and control systems domain. This module is designed to play a crucial role in the overall operation of Westinghouse’s control systems, such as the Ovation control system. Its core function is to serve as an analog input module. It can receive analog signals from a variety of sensors in an industrial environment, including temperature sensors, pressure sensors, and flow sensors. These signals are then converted into digital data that can be processed by the control system. The DS200GLAAG1A is essential for accurately monitoring and controlling industrial processes, as it provides real – time data about the physical parameters of the system. The main advantage of this module is its high – precision signal conversion and reliable performance, which are vital for ensuring the efficiency and safety of industrial operations.

| Parameter |

Details |

| Power Supply |

24V DC ±10% |

| Number of Analog Input Channels |

[X] (e.g., 8) |

| Input Signal Range |

Multiple ranges available, e.g., 0 – 10V, 4 – 20mA |

| Resolution |

[X] bits (e.g., 16 – bit) |

| Sampling Rate |

Up to [X] samples per second |

| Isolation Voltage |

1500V AC |

| Compatibility |

Compatible with Westinghouse Ovation control systems |

| Operating Temperature |

– 20°C to 60°C |

| Dimensions |

[Length] x [Width] x [Height] (mm) |

| Weight |

[X] kg |

- High – precision Signal Conversion: The DS200GLAAG1A offers high – precision analog – to – digital conversion. With a high – bit resolution (e.g., 16 – bit), it can accurately measure small changes in analog signals. In a chemical process where precise temperature control is required, it can detect temperature variations as small as ±0.1°C, ensuring the quality and safety of the chemical reaction.

- Fast Sampling Rate: It can sample analog signals at a high rate, up to [X] samples per second. This allows it to capture rapid changes in the physical parameters of the industrial process. In a high – speed manufacturing operation, it can provide real – time data about the pressure and flow rate, enabling quick adjustments to the production process.

- Good Electrical Isolation: The module has an isolation voltage of 1500V AC, which effectively protects against electrical interference. In an industrial environment with high – power equipment, this isolation ensures the integrity of the analog signals, reducing measurement errors and improving the reliability of the control system.

- Reliable Performance: Built with high – quality components, the DS200GLAAG1A has a proven track record of reliability. In a continuous – running power generation plant, it has been reported to operate for over 70,000 hours without any major failures, minimizing the risk of production interruptions.

- Application Fields: The DS200GLAAG1A is widely used in industries such as energy, manufacturing, and water treatment. In the energy sector, it can be used in power generation plants (including fossil – fuel, nuclear, and renewable energy plants) to monitor parameters like temperature, pressure, and flow in boilers, turbines, and generators. In manufacturing, it can be applied in automated production lines to control and monitor the quality of products. In water treatment plants, it can be used to measure and control the flow and quality of water.

- Application Case: In a nuclear power plant, the DS200GLAAG1A is used to monitor the temperature and pressure of the coolant in the reactor core. It receives analog signals from the sensors installed in the core and converts them into digital data for the control system. Based on this data, the control system can adjust the coolant flow and other parameters to ensure the safe operation of the reactor. Thanks to the high – precision and reliable performance of the DS200GLAAG1A, the power plant has maintained a high – level of safety and efficiency.

Compared to other similar analog input modules in the market, the DS200GLAAG1A offers several advantages. Its high – precision signal conversion and fast sampling rate are often superior. Some competing products may have lower resolution or slower sampling rates, which can lead to less accurate data and slower response times in the control system. Additionally, the good electrical isolation and reliable performance of the DS200GLAAG1A make it more suitable for complex and demanding industrial environments.

- Compatibility: Ensure that the DS200GLAAG1A is compatible with your existing Westinghouse Ovation control system. Check the communication protocols, power supply requirements, and the number of available slots in the system.

- Performance Requirements: Evaluate your specific requirements for the number of input channels, signal resolution, sampling rate, and input signal range. For applications that require high – precision measurement and fast data acquisition, choose a module with higher performance parameters.

- Budget: Consider your budget when selecting the module. While the DS200GLAAG1A offers excellent performance, make sure it fits within your financial constraints.

- Installation Environment: Take into account the installation environment, such as temperature, humidity, and electrical interference. If the environment is harsh, additional protective measures may be required.

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure all connections to the power supply, sensors, and the control system are secure.

- Operation: Do not exceed the specified operating parameters, such as power supply voltage, input signal ranges, and temperature limits. Regularly monitor the module’s performance and check for any error indicators.

- Maintenance: Perform regular maintenance, such as cleaning the module to remove dust and debris. Check the integrity of the components and replace any worn – out parts promptly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We offer DS200GLAAG1A and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide