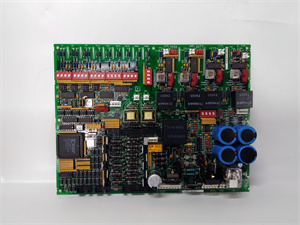

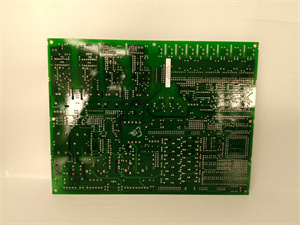

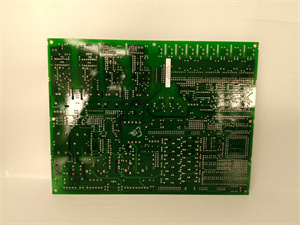

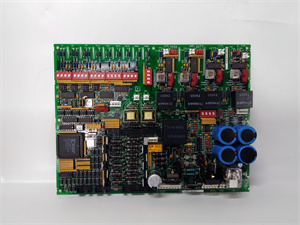

Description

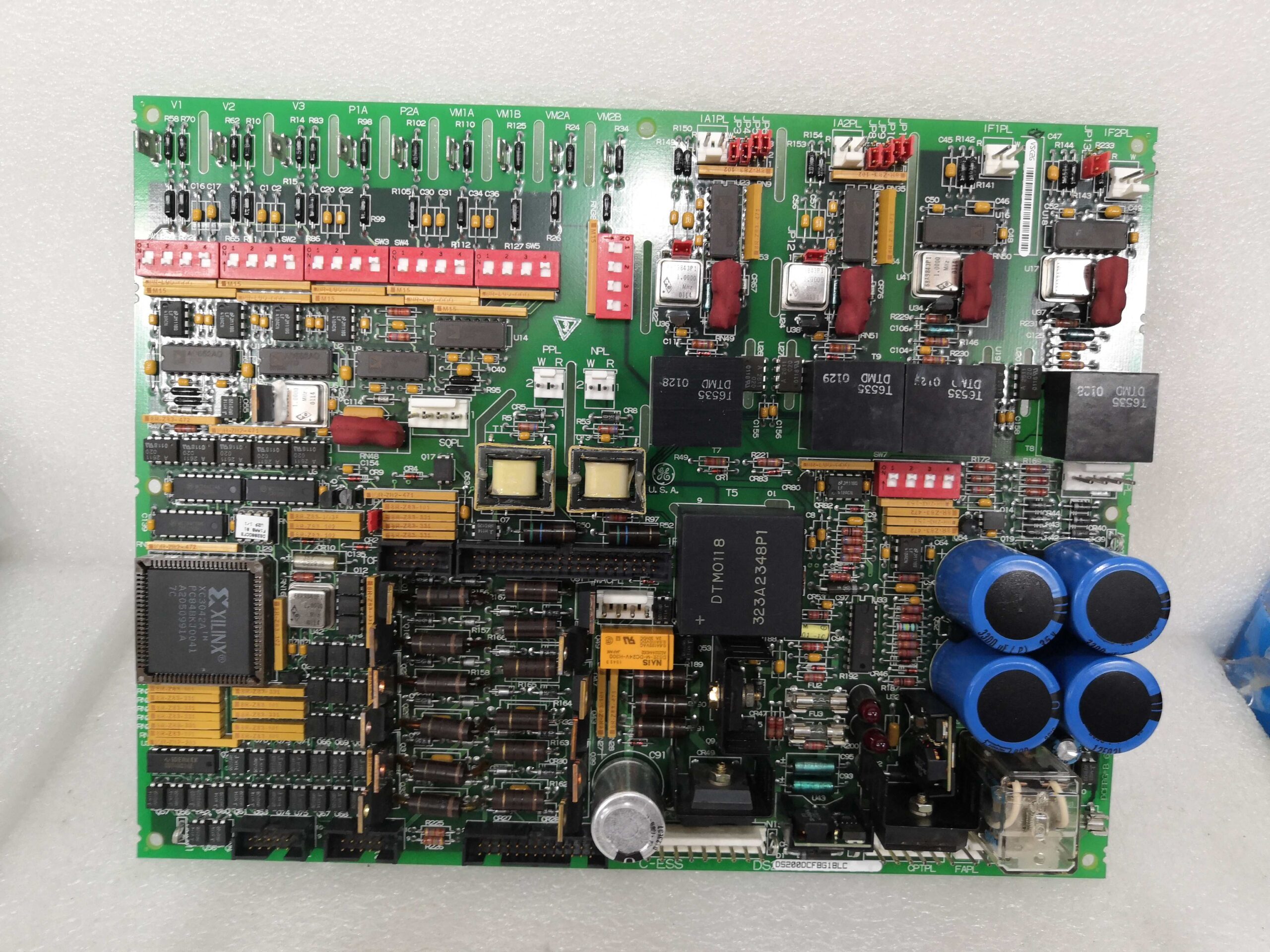

GE Fanuc

DS200DCFBG1BLC is a high-performance automation component designed for distributed control systems (DCS) and industrial IoT (IIoT) applications. As a core module of the IAS4.0 framework,

DS200DCFBG1BLC enables flexible, modular, and connected manufacturing by integrating advanced features like distributed control, embedded security, and multi-directional communication. It supports seamless data collection from sensors and devices, facilitating real-time analytics, predictive maintenance, and optimized decision-making. The module reduces hardware dependency, lowers total cost of ownership, and accelerates design cycles through pre-certified applications and libraries. Ideal for industries requiring scalable automation,

DS200DCFBG1BLC enhances operational efficiency and supply chain resilience.

| Parameter |

Specification |

| Voltage |

200V AC |

| Current |

N/A (signal-level processing) |

| Interface Type |

Multi-protocol (Ethernet, Modbus) |

| Compatibility |

GE DCS systems, industrial IoT platforms |

| Communication |

M2M, edge-to-cloud connectivity |

| Security |

Embedded cybersecurity protocols |

| Operating Temperature |

-40°C to 85°C (industrial grade) |

DS200DCFBG1BLC

- High Reliability: Built with industrial-grade components and embedded security, ensuring continuous operation in harsh environments.

- Flexible Integration: Reduces 机柜 space and hardware reliance through software-driven architecture, supporting rapid reconfiguration of production lines.

- Real-Time Analytics: Enables seamless data flow to AI/ML platforms, improving predictive maintenance (reducing downtime by up to 30% in automotive applications).

- Shortened Design Cycles: Pre-certified libraries and modular configurations cut development time by 20–25% for machine control systems.

- Scalability: Supports multi-directional communication (M2M, edge-to-cloud) for scalable IIoT deployments.

Industries: Manufacturing (automotive, food & beverage), energy, material handling, and industrial automation.

Case Study: A leading automotive manufacturer deployed DS200DCFBG1BLC to transform a legacy production line. The module enabled real-time reconfiguration of vehicle models (e.g., switching between SUVs and sedans on the same line), reducing changeover time by 40% and improving supply chain resilience amid component shortages.

Compared to similar DCS modules, DS200DCFBG1BLC offers superior integration with GE’s IAS4.0 ecosystem, combining distributed control, embedded security, and IIoT capabilities in a single unit. Its pre-certified applications and modular design reduce upfront engineering costs by 15–20% compared to generic solutions, while its real-time data processing enhances operational agility.

DS200DCFBG1BLC

- Compatibility: Ensure alignment with existing GE DCS systems (e.g., IC698/IC697 PLC series).

- Environment: Verify temperature/humidity ranges match operational conditions (e.g., harsh factory floors vs. controlled environments).

- Scalability: Choose based on required communication protocols (e.g., Ethernet for high-speed data transfer).

- Budget: Balance upfront costs with long-term savings from reduced maintenance and downtime.

- Installation: Follow ESD (electrostatic discharge) protection protocols during handling.

- Security: Regularly update firmware to address cybersecurity vulnerabilities.

- Maintenance: Schedule annual inspections to clean connectors and verify signal integrity.

- Environment: Avoid exposure to corrosive chemicals or extreme vibrations.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide