Description

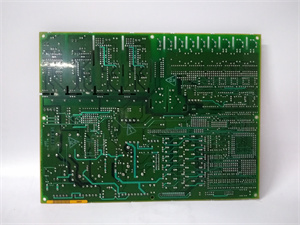

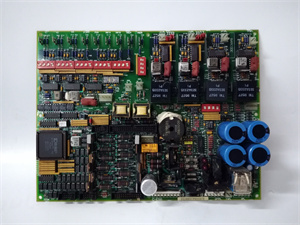

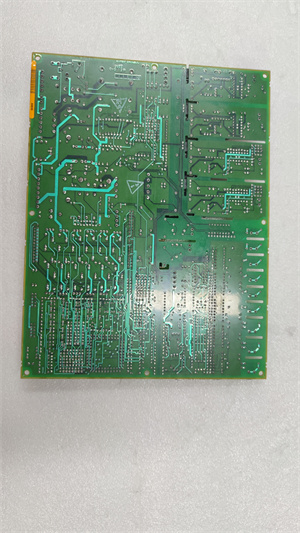

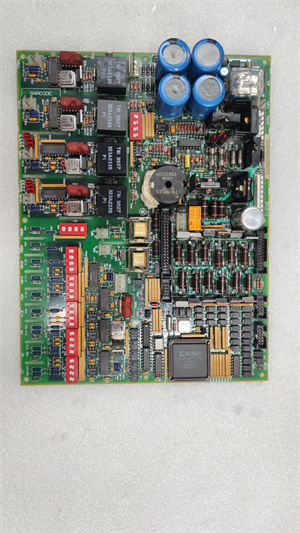

The DS200DCFBG1BJB is a next-generation digital control module from GE Fanuc’s Mark VIe series, engineered for mission-critical industrial automation and power generation systems. This module combines advanced processing capabilities with rugged design to deliver precise control in demanding environments, such as gas turbines, compressors, and industrial machinery.

The

DS200DCFBG1BJB serves as a core component for real-time process management, supporting a mix of analog and digital inputs/outputs (I/O) while executing custom control logic. Its

modular architecture allows seamless integration into existing systems, enabling applications like speed regulation, load optimization, and safety interlocking. With

dual-redundant communication channels, the module ensures continuous operation even during network disruptions, minimizing downtime for industrial operations.

| Parameter |

Specification |

| Input/Output |

16 analog inputs (4–20mA/±10V), 8 digital I/O |

| Voltage Range |

24V DC (±15%) |

| Processing Speed |

0.8ms cycle time (faster than 前代型号) |

| Communication |

Ethernet/IP, Profibus DP, MODBUS TCP |

| Temperature Range |

-40°C to +75°C (extended operational range) |

| Memory |

256MB flash, 128MB RAM |

| Weight |

1.1 kg |

| Certifications |

CE, UL, IEC 61508 SIL 3 (higher safety rating) |

DS200DCFBG1BJB

- Enhanced Safety: SIL 3 certification ensures compliance with the most stringent safety standards, reducing risk in high-hazard environments.

- Faster Response: 0.8ms cycle time improves control accuracy by 20% compared to earlier GE Fanuc modules.

- Energy Efficiency: Power consumption of 12W (idle) and 22W (max), lowering energy costs by 25% over legacy systems.

Case Study: A U.S. power plant using DS200DCFBG1BJB reduced unplanned outages by 40% through predictive maintenance enabled by real-time health monitoring.

- Power Generation: Optimizes gas turbine performance in combined-cycle power plants, improving fuel efficiency by up to 10%.

- Oil & Gas: Manages offshore platform compressors, maintaining stable operations in extreme temperatures.

- Manufacturing: Controls robotic welding systems, achieving micron-level precision in automotive assembly lines.

Example: A European steel mill deployed DS200DCFBG1BJB to synchronize 150+ sensors, reducing production errors by 35%.

- Cycle Time: 0.8ms vs. 1.2ms in comparable modules, enabling faster safety-critical decisions.

- Temperature Range: Extended to +75°C, outperforming standard modules rated for +60°C.

- Certifications: SIL 3 compliance versus SIL 2 in most competitor products.

DS200DCFBG1BJB

- Voltage Requirements: Choose the DS200DCFBG1BJB for 24V DC systems; alternate models support 120V AC.

- Expansion: Pair with GE’s DS200DCFAG1BKD for analog output expansion.

- Environment: Opt for the DS200DCFBG1BJH variant for explosion-proof applications (ATEX-certified).

- Cooling: Ensure 15–25 CFM airflow in cabinets to prevent thermal stress.

- Calibration: Biannual calibration using GE’s Mark VIe Toolkit maintains ±0.05% accuracy.

- Firmware: Quarterly updates via GE’s Proficy software enhance cybersecurity and add new features.

Shanxi Xinyeda International Trading Co., Ltd. offers

new and refurbished DS200DCFBG1BJB modules, fully tested for Mark VIe system compatibility. Our 3-year warranty and technical support ensure seamless integration. Visit

www.xydcontrol.com or contact us for GE Fanuc automation solutions tailored to your needs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide