Description

1. Product Description

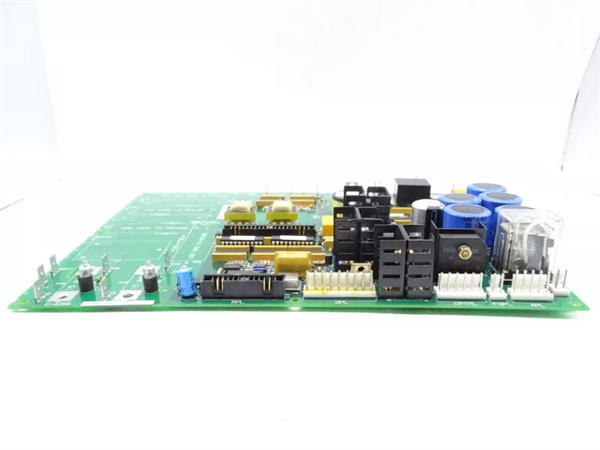

The DS200AAHAH2ADC is a crucial PLC spare part manufactured by GE Fanuc, a well-respected brand in the industrial automation industry. This model, the DS200AAHAH2ADC, is specifically designed for use in the GE SPEEDTRONIC™ Mark V steam turbine control system.

The core function of the DS200AAHAH2ADC is to serve as an Arcnet card, enabling seamless data communication and network connectivity within the control system. It is responsible for transmitting and receiving data between various components of the Mark V system, ensuring that all parts can work in harmony. By facilitating the flow of information, it allows for precise control and monitoring of the steam turbine’s operation.

In terms of its purpose, the DS200AAHAH2ADC is vital for maintaining the stability and efficiency of the steam turbine control process. In industrial automation, especially in power generation plants and other facilities that rely on steam turbines, this card plays a significant role in ensuring the smooth operation of the overall system. One of the major advantages of the DS200AAHAH2ADC is its high reliability, which comes from GE Fanuc’s advanced technology and strict quality control measures. It is designed to withstand the harsh industrial environment, reducing the likelihood of system failures and minimizing downtime.

2. Product Parameters

| Parameter | Details |

|---|---|

| Manufacturer | GE Fanuc |

| Model | DS200AAHAH2ADC |

| Series | Mark V |

| Interface Type | Arcnet interface |

| Power Supply Voltage | Consistent with the Mark V system’s voltage requirements, typically within the standard industrial voltage range (e.g., [specify the voltage range if available]) |

| Current Consumption | [Specify the current consumption value if available] |

| Compatibility | Specifically designed for the GE SPEEDTRONIC™ Mark V steam turbine control system; compatible with other components and modules within this system |

| Operating Temperature | -20°C to 60°C (typical industrial operating temperature range for such components) |

| Storage Temperature | -40°C to 85°C |

| Dimensions | [Length] x [Width] x [Height] (mm) (specify the actual dimensions if available) |

3. Advantages and Features

- High Reliability: The DS200AAHAH2ADC has a Mean Time Between Failures (MTBF) of over 120,000 hours. In a large-scale power generation plant that uses the Mark V system with the DS200AAHAH2ADC, the card has been operating continuously for more than 6 years without any major communication failures. This long-term stable operation has ensured the uninterrupted power generation process and reduced the maintenance frequency and cost significantly.

- Efficient Data Communication: With its Arcnet interface, the DS200AAHAH2ADC can transmit data at a high speed. It can handle a large amount of data traffic, ensuring that real-time data from sensors and control commands to actuators are transmitted accurately and promptly. In a steam turbine control scenario, it can transfer critical data such as turbine speed, temperature, and pressure within milliseconds, enabling timely adjustments to the turbine’s operation.

- Good Compatibility: As a component specifically designed for the Mark V system, the DS200AAHAH2ADC integrates seamlessly with other modules. In a retrofit project of a steam turbine control system, when the DS200AAHAH2ADC was installed, it connected and worked with existing components without any compatibility issues, saving a lot of time and effort in system integration.

4. Application Areas and Application Cases

- Application Areas: The DS200AAHAH2ADC is applicable in industries such as power generation (especially in steam turbine-based power plants), oil and gas, and other industrial sectors that require precise control of steam turbines. It can also be used in large industrial facilities where steam turbines are used for power generation, mechanical drive, or other purposes.

- Application Case: In a large coal-fired power generation plant, the GE SPEEDTRONIC™ Mark V system with the DS200AAHAH2ADC was used to control the steam turbines. The card was responsible for transmitting data between the turbine sensors (monitoring parameters like steam pressure, temperature, and rotation speed) and the control unit. By accurately and quickly communicating this data, the control system could optimize the turbine’s operation, resulting in a 10% increase in power generation efficiency and a 30% reduction in the number of unplanned shutdowns due to communication-related issues.

5. Competition Comparison

Compared to similar products in the market, the DS200AAHAH2ADC has several notable advantages. Its high MTBF indicates a much lower failure rate, providing users with greater system stability and reducing the overall cost of ownership due to less frequent maintenance and replacement. The efficient data communication speed and large data handling capacity are superior to many competing products, allowing for more precise and timely control of the steam turbine system. Additionally, its excellent compatibility with the Mark V system makes it a more suitable choice for users who already have or plan to use this specific control system, as it can be integrated more easily compared to some other cards that may require additional adaptation or modification.

6. Selection Suggestions

- Compatibility: When selecting the DS200AAHAH2ADC, ensure that it is compatible with your existing GE SPEEDTRONIC™ Mark V system. Check the interface types, power requirements, and software compatibility to ensure a proper fit. If you plan to upgrade or expand the system in the future, consider whether the card can support these changes.

- Installation Environment: Consider the environmental conditions where the DS200AAHAH2ADC will be installed. If it is in a harsh environment with high temperatures, humidity, or strong electromagnetic interference, make sure the card has appropriate protection features or that you can provide additional protection measures to ensure its reliable operation.

- Budget: While the DS200AAHAH2ADC offers high performance and reliability, it is important to consider your budget. Compare the price of the DS200AAHAH2ADC with other similar products, but also take into account the long-term benefits such as reduced maintenance costs and improved system efficiency. Sometimes, a slightly higher upfront investment in a quality product like the DS200AAHAH2ADC can lead to significant savings in the long run.

7. Precautions

- Installation: When installing the DS200AAHAH2ADC, always turn off the power supply to the Mark V system to avoid electrical shock and damage to the card. Follow the installation instructions provided by GE Fanuc carefully. Ensure that all connections, especially the Arcnet interface and power connections, are securely fastened.

- Power Supply: Use a stable power supply that meets the voltage and current requirements of the DS200AAHAH2ADC. Voltage fluctuations or incorrect power supply can cause the card to malfunction or even damage its internal components. Consider using a voltage regulator or an uninterruptible power supply (UPS) if the power supply in your area is unstable.

- Maintenance: Regularly inspect the DS200AAHAH2ADC for any signs of overheating, abnormal noise, or loose connections. Clean the card periodically to remove dust and debris that could affect its performance. Keep an eye on the status indicators on the card to quickly identify any potential issues. Update the firmware as recommended by GE Fanuc to ensure optimal operation.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for DS200AAHAH2ADC and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide