Description

The

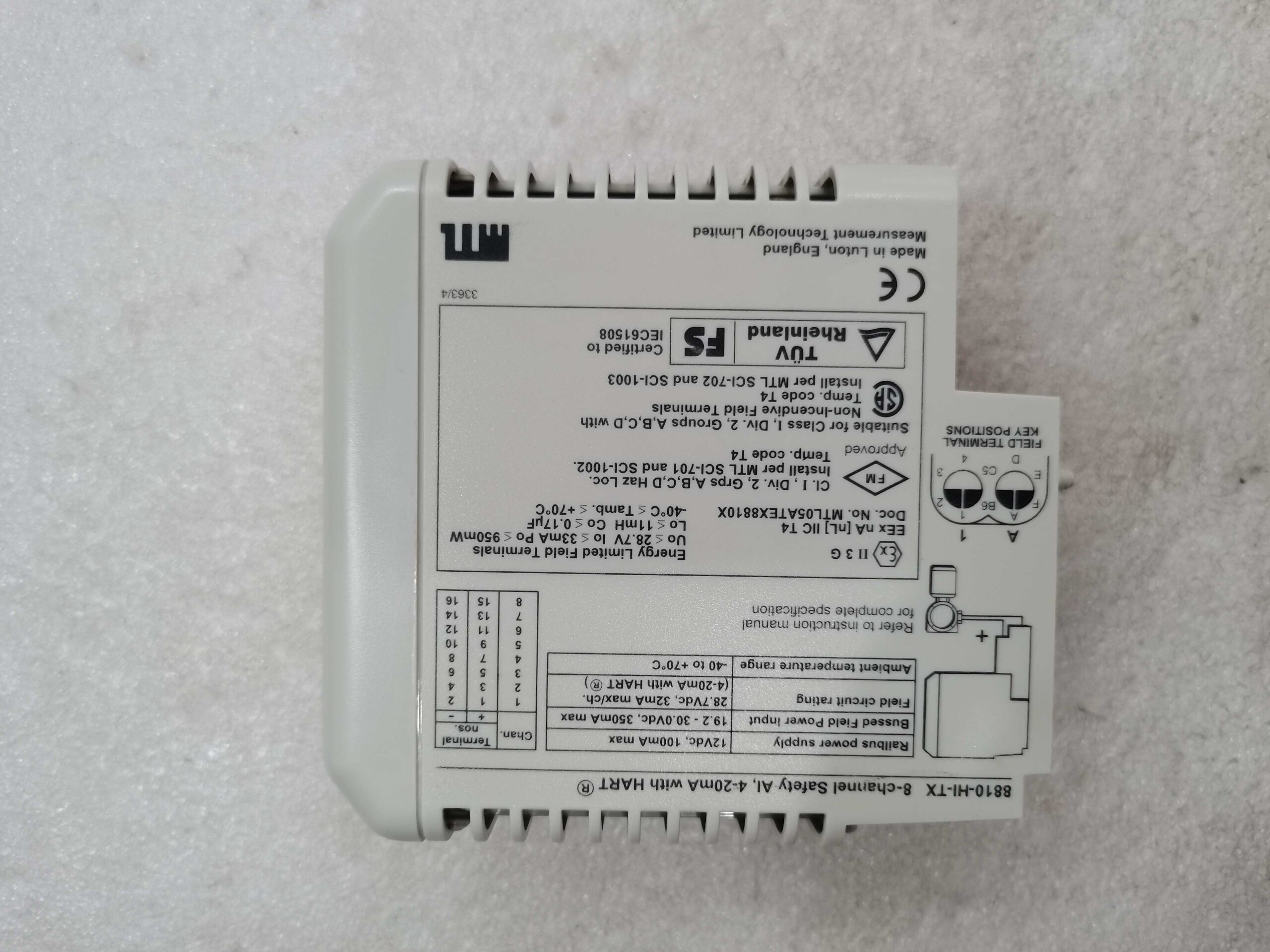

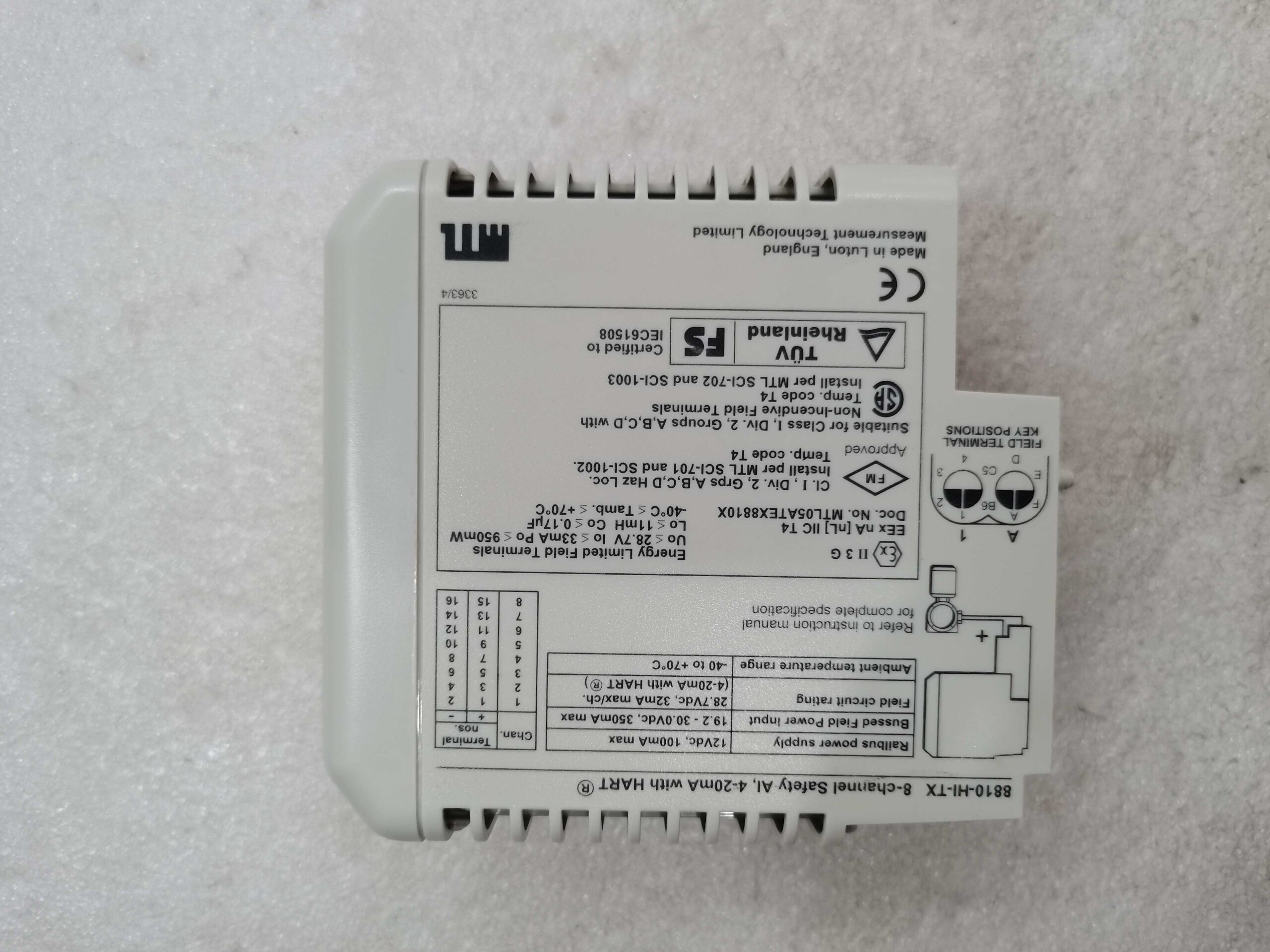

8810 – HI – TX is a high – performance transmitter module designed for critical industrial applications. It is engineered to meet the demanding requirements of accurate signal transmission and control in complex industrial environments.

The core function of the 8810 – HI – TX is to convert input signals from various sensors into standardized output signals that can be easily processed by control systems. These input signals can come from a wide range of sensors such as pressure sensors, temperature sensors, and flow sensors. The transmitter then sends the processed output signals to Programmable Logic Controllers (PLCs), Distributed Control Systems (DCSs), or other monitoring and control devices.

This product is widely used in industries like oil and gas, chemical processing, and power generation. In the oil and gas industry, it can be used to transmit pressure and temperature data from wellheads to control centers, ensuring safe and efficient production operations. In chemical processing plants, it helps in monitoring and controlling the flow and composition of various chemicals.

One of the key advantages of the 8810 – HI – TX is its high accuracy. It can provide precise signal conversion with a very low margin of error, which is crucial for maintaining the quality and safety of industrial processes. Additionally, it has excellent stability over time, reducing the need for frequent recalibration. Another advantage is its robustness. It is designed to withstand harsh environmental conditions such as high temperatures, humidity, and vibrations, making it suitable for use in remote and challenging industrial locations.

| Parameter |

Details |

| Power Supply |

12 – 36V DC |

| Input Signal Range |

4 – 20mA, 0 – 10V (configurable) |

| Output Signal Range |

4 – 20mA, 0 – 10V (configurable) |

| Accuracy |

±0.1% of full – scale |

| Linearity |

±0.05% of full – scale |

| Temperature Range |

– 40°C to 85°C (operating), – 50°C to 95°C (storage) |

| Communication Interface |

Modbus RTU over RS – 485 |

| Compatibility |

Compatible with most major PLC and DCS systems |

- High Accuracy: With an accuracy of ±0.1% of full – scale, the 8810 – HI – TX ensures precise signal conversion. In a chemical plant, this high accuracy helps in maintaining the correct chemical ratios during the production process, reducing waste and improving product quality.

- Stability: It offers long – term stability with a drift of less than 0.01% per year. In a power generation plant, this stability ensures that the control systems receive consistent and reliable data, reducing the risk of equipment malfunctions.

- Robust Design: The 8810 – HI – TX is built to withstand harsh industrial environments. In an offshore oil platform, it can operate reliably in high – humidity and high – vibration conditions, ensuring continuous data transmission.

- Application Areas: The 8810 – HI – TX is used in oil and gas exploration and production, chemical manufacturing, power generation, and water treatment plants.

- Application Case: In a large – scale water treatment plant, the 8810 – HI – TX was installed to transmit the water flow rate and pressure data from different parts of the plant to the central control system. The high accuracy of the transmitter allowed for precise control of the water treatment process, resulting in a 15% reduction in chemical usage and a 10% improvement in water quality.

Compared to similar products in the market, the 8810 – HI – TX offers a higher level of accuracy and stability. While some competing transmitters may have a lower initial cost, they often lack the long – term reliability and precision that the 8810 – HI – TX provides. Its wide input and output signal range configurability also gives it an edge over products with more limited options.

- Compatibility: Ensure that the 8810 – HI – TX is compatible with your existing control system. Check the communication protocol, input and output signal requirements, and power supply compatibility.

- Environmental Conditions: Consider the operating environment of the transmitter. If it will be installed in a harsh environment, ensure that the 8810 – HI – TX can withstand the temperature, humidity, and vibration levels.

- Accuracy Requirements: Evaluate your accuracy requirements. If your application demands high – precision signal conversion, the 8810 – HI – TX’s accuracy of ±0.1% of full – scale may be a critical factor.

- Budget: Compare the cost of the 8810 – HI – TX with your budget. While it offers high – end features, consider the long – term savings in terms of reduced maintenance and improved process efficiency.

- Installation: Follow the installation instructions carefully. Ensure proper grounding to prevent electrical interference. Connect the input and output signals correctly to avoid signal errors.

- Maintenance: Regularly check the transmitter for any signs of damage or malfunction. Clean the module to prevent dust accumulation, which may affect its performance.

- Safety: When working with the 8810 – HI – TX, follow all safety procedures. Disconnect the power supply before performing any maintenance or repair work to avoid electric shock.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for 8810 – HI – TX and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide