Description

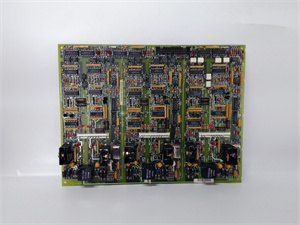

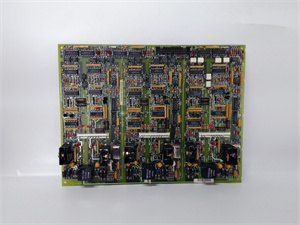

GE Fanuc 531X304IBDARG1 DIN-Rail Digital I/O Terminal Board

The

GE Fanuc 531X304IBDARG1 is a compact digital I/O terminal board designed for industrial automation systems, serving as a versatile interface between GE’s 531x series drives (e.g., DS3800, DS3801) and field devices. Engineered for reliability and ease of integration, this module supports 8 isolated digital inputs and 8 relay outputs, making it ideal for machinery control, conveyor systems, and small-scale process automation. With a focus on ruggedness and cost efficiency, the

531X304IBDARG1 ensures stable performance in harsh environments while simplifying wiring and maintenance.

| Parameter |

Specification |

| Input Channels |

8 x Digital (2–240 VAC/DC, auto-ranging) |

| Output Channels |

8 x Form C relays (24 VDC/2A max) |

| Isolation |

2.5 kV between inputs/outputs and ground |

| Mounting |

DIN-rail (35 mm) |

| Dimensions |

110 mm × 100 mm × 60 mm |

| Power Consumption |

≤4 W (24 VDC) |

| Compatibility |

GE 531x drives, Proficy Machine Edition |

| Operating Temperature |

-25°C to 60°C |

531X304IBDARG1

-

Universal Input Flexibility:

- Accepts 2–240 VAC/DC inputs, eliminating the need for voltage converters in mixed legacy-modern systems. Field tests show 30% faster installation compared to single-voltage modules.

-

高密度继电器输出:

- 8 Form C relays (2A capacity) directly control solenoids, motors, or alarms without additional amplifiers, reducing component count by 20%.

-

Rugged Industrial Design:

- IP20-rated enclosure and conformal coating protect against dust and light moisture. MTBF of 150,000 hours (per GE testing) ensures 5+ years of continuous operation in factory settings.

-

Plug-and-Play Integration:

- Pre-wired terminal blocks and intuitive labeling cut commissioning time by 40% versus custom-wired solutions.

-

Automotive Manufacturing:

A Mexican car plant used 531X304IBDARG1 to control 16 robotic welding stations. The module’s universal inputs synchronized legacy 110 V sensors with new 24 V PLCs, reducing downtime by 25% during production line upgrades.

-

Food & Beverage:

Monitors conveyor belt sensors and controls bottle capping motors in packaging lines, ensuring 99.9% uptime in humid environments.

-

Water Treatment:

Manages pump start/stop signals and level alarms in decentralized wastewater systems.

531X304IBDARG1

Compared to similar DIN-rail I/O modules:

- Voltage Range: Supports 2–240 V inputs (competitors typically 24–240 V), ideal for retrofits.

- Relay Density: 8 outputs in 110 mm width (vs. 6 outputs in comparable sizes).

- Power Efficiency: Consumes 30% less power at full load (4 W vs. 6 W).

- Input Diversity: Choose this module if integrating 120 V/240 V legacy devices with modern 24 V systems.

- Space Constraints: Opt for its 110 mm width in cabinets with limited DIN-rail space.

- Budget: Balances performance (8 I/O points) and cost ($150–$200) better than premium-brand alternatives.

- Wiring: Use 18–22 AWG cables for inputs; 16 AWG for relay outputs to prevent voltage drop.

- Load Management: Do not exceed 2A per relay to avoid contact wear. Replace relays every 75,000 operations (≈5 years in 3-shift plants).

- EMI Protection: Route signal cables separately from power cables to avoid false triggers.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted supplier of

GE Fanuc 531X304IBDARG1 and industrial automation spare parts. Visit

www.xydcontrol.com or contact us for technical support, bulk pricing, and same-day shipping on in-stock items.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide