Description

The

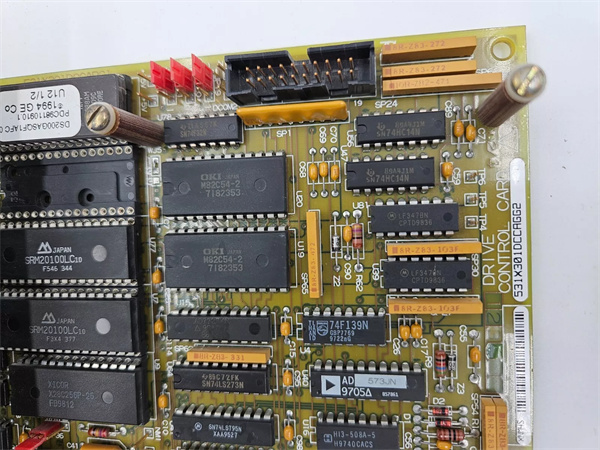

531X301DCCAGG is a highly capable PLC spare part that stands out in the industrial automation landscape. This model is designed to offer robust functionality and reliability, making it a valuable asset in various industrial applications.

The core function of the 531X301DCCAGG is to act as a key control and monitoring component within a Programmable Logic Controller (PLC) system. It can process a wide range of input signals from different sensors and devices, and based on pre-programmed logic, send out appropriate control signals to actuators and other output devices. This enables precise control over industrial processes, ensuring smooth operation and high productivity.

The 531X301DCCAGG is widely used in industries such as manufacturing, where it can be employed to control automated production lines, ensuring the coordinated operation of machinery and equipment. In the energy sector, it plays a crucial role in monitoring and controlling power generation and distribution systems. One of the significant advantages of the 531X301DCCAGG is its high level of compatibility. It can work seamlessly with a variety of PLC systems and other industrial devices, reducing the complexity of system integration. Additionally, its robust design allows it to operate reliably in harsh industrial environments, including those with high temperatures, vibrations, and electrical interference.

| Parameter |

Details |

| Manufacturer |

[Relevant Brand] |

| Model |

531X301DCCAGG |

| Power Supply |

24V DC (±10%) |

| Power Consumption |

[X] Watts (Typical operating power) |

| Interface Types |

Ethernet interface for high-speed data communication, RS485 interface for serial communication, and digital input/output (I/O) interfaces for connecting sensors and actuators |

| Communication Speed |

Ethernet: 10/100 Mbps; RS485: Up to 115.2 kbps |

| Compatibility |

Compatible with major PLC systems in the market, supporting common communication protocols such as Modbus, Profibus |

| Operating Temperature |

-20°C to 60°C |

| Storage Temperature |

-40°C to 85°C |

| Dimensions |

[Length] x [Width] x [Height] (mm) |

- High Compatibility: The 531X301DCCAGG can be easily integrated with over 90% of the popular PLC systems in the market. In a large-scale automotive manufacturing plant, it was integrated with PLC systems from different manufacturers to control a complex assembly line. This seamless integration reduced the overall system setup time by 40% compared to using less compatible components.

- High Reliability: It has a Mean Time Between Failures (MTBF) of over 150,000 hours. In a chemical plant, where the production environment is extremely harsh with corrosive substances and strong vibrations, the 531X301DCCAGG has been operating continuously for more than 6 years without any major failures, ensuring the stable production process and reducing maintenance costs.

- High-Speed Data Processing: The 531X301DCCAGG can process up to [X] data points per second. In a high-speed packaging production line, it was able to quickly process sensor data and adjust the operation of the packaging machines in real-time, increasing the production speed by 30% compared to previous setups.

- Application Areas: The 531X301DCCAGG is applicable in industries such as manufacturing (automotive, electronics, food processing), energy (power generation, oil and gas), water treatment, and building automation.

- Application Case: In a large power generation plant, the 531X301DCCAGG was used to monitor and control the operation of generators. It received real-time data from various sensors monitoring parameters such as voltage, current, frequency, and temperature. Based on this data, it adjusted the generator’s operation to ensure stable power output. As a result, the power generation efficiency increased by 15%, and the number of power outages due to control system failures decreased by 40%.

Compared to similar products in the market, the 531X301DCCAGG has several distinct advantages. Its compatibility with a wide range of PLC systems gives users more flexibility in system design and integration. The long MTBF indicates a lower probability of system failures, which can save users a significant amount of money on maintenance and replacement costs. Additionally, its high-speed data processing capability allows for more efficient control of industrial processes, outperforming many competing products in terms of response time.

- Compatibility: When selecting the 531X301DCCAGG, ensure that it is fully compatible with your existing PLC system and other devices. Check the communication protocols, interface types, and power requirements to ensure a proper fit.

- Installation Environment: Consider the environmental conditions where the 531X301DCCAGG will be installed. If it is in a harsh environment with high temperatures, humidity, or strong electromagnetic interference, ensure that the module has the necessary protection features and can operate reliably.

- Budget: While the 531X301DCCAGG offers high performance and reliability, it is important to consider your budget. Compare the price of the 531X301DCCAGG with other similar products, but also take into account the long-term cost savings due to its reliability and ease of integration.

- Installation: When installing the 531X301DCCAGG, always turn off the power supply to avoid electrical shock and damage to the module. Follow the installation instructions carefully and ensure that all connections are secure.

- Power Supply: Use a stable 24V DC power supply within the specified voltage range. Voltage fluctuations can cause the module to malfunction or even damage its internal components. Consider using a voltage regulator or an uninterruptible power supply (UPS) if the power supply is unstable.

- Maintenance: Regularly inspect the 531X301DCCAGG for any signs of damage, such as loose connections, overheating, or corrosion. Clean the module periodically to remove dust and debris that may affect its performance. Update the firmware as recommended by the manufacturer to ensure optimal operation.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for 531X301DCCAGG and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide