Description

The

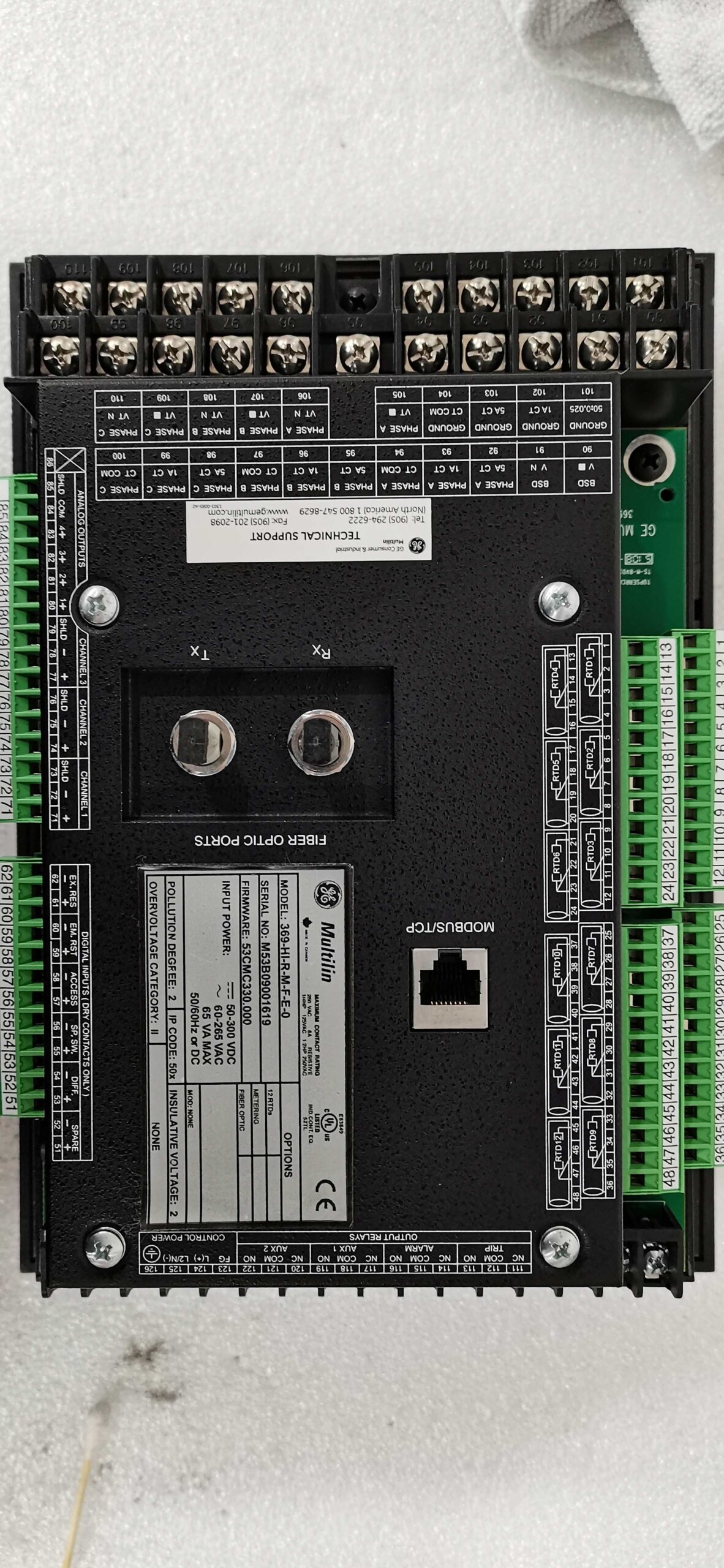

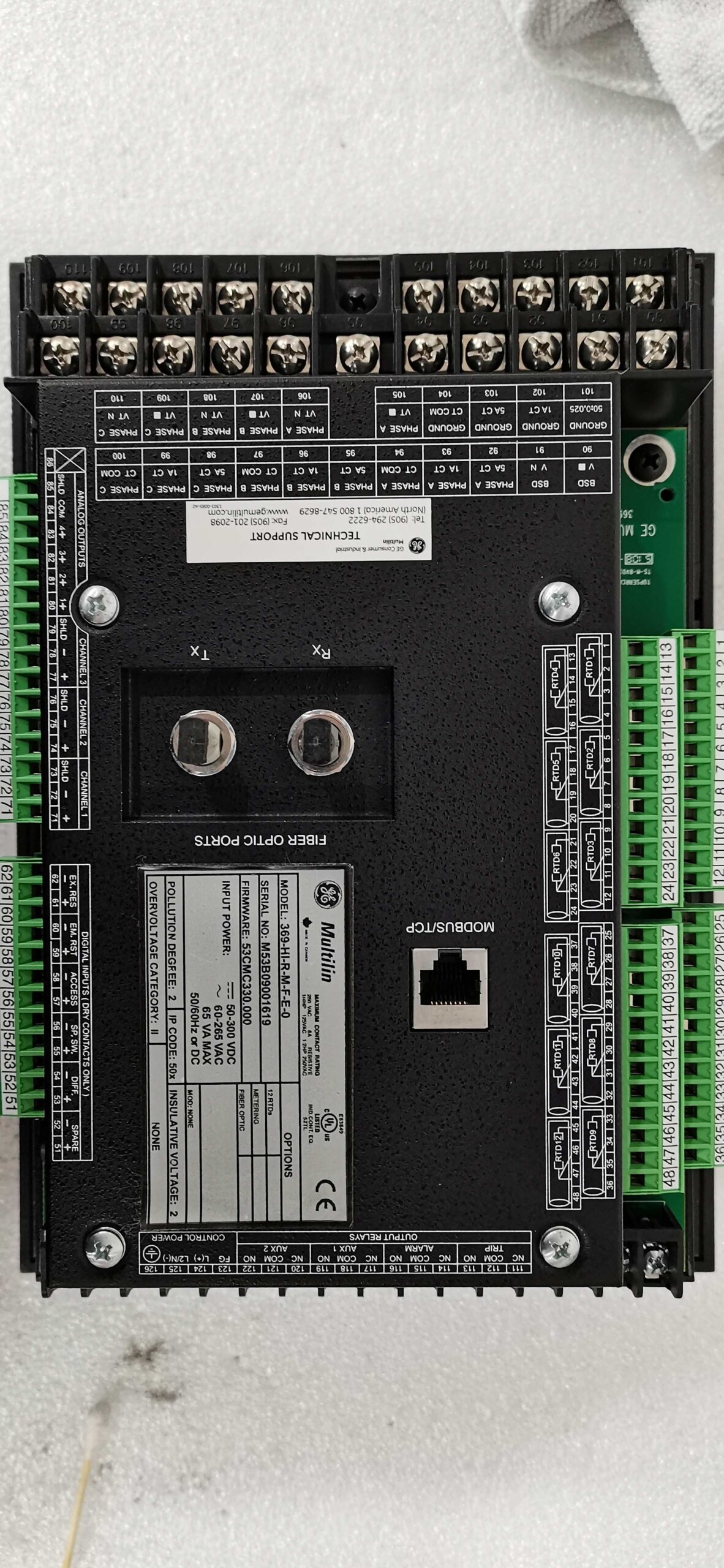

369 – HI – R – M – F – E – 0 – 0 is a specialized PLC spare part that is often associated with a well – established brand in the industrial automation industry. This product is designed to fulfill a specific set of functions within an industrial control system. Its core function is to act as an interface or a control module that can handle high – intensity operations related to input, output, and data processing.

In industrial applications, the 369 – HI – R – M – F – E – 0 – 0 is widely used. In manufacturing settings, it can be used to control complex machinery operations, such as the movement of large – scale presses or the precision cutting of materials. In the energy sector, it can play a role in monitoring and controlling power distribution systems, ensuring stable and efficient power supply. One of the main advantages of the 369 – HI – R – M – F – E – 0 – 0 is its high – reliability design. It is built to withstand harsh industrial environments, including high temperatures, vibrations, and electrical interference. Additionally, it offers excellent flexibility in terms of configuration, allowing it to be adapted to different industrial control requirements.

| Parameter |

Details |

| Power Supply |

110 – 240V AC or 24V DC (selectable) |

| Input Channels |

[X] digital input channels, [X] analog input channels |

| Output Channels |

[X] digital output channels, [X] analog output channels |

| Input Signal Types |

Digital: 24V DC; Analog: 0 – 10V, 4 – 20mA |

| Output Signal Types |

Digital: 24V DC; Analog: 0 – 10V, 4 – 20mA |

| Communication Interface |

Ethernet, Modbus RTU, Profibus |

| Operating Temperature |

– 20°C to 70°C |

| Storage Temperature |

– 40°C to 85°C |

| Compatibility |

Compatible with multiple mainstream PLC series |

- High Reliability: The 369 – HI – R – M – F – E – 0 – 0 has a mean time between failures (MTBF) of over [X] hours. In a mining operation, it has been operating continuously in a harsh environment with high dust and vibrations for several years without major failures, ensuring the stable operation of the mining equipment control system.

- Flexible Configuration: It can be easily configured to meet different industrial control requirements. In a food processing plant, it can be adjusted to control different types of processing equipment, such as mixers, ovens, and packaging machines, by simply re – programming the input and output settings.

- Multiple Communication Interfaces: The availability of Ethernet, Modbus RTU, and Profibus interfaces provides great flexibility for system integration. In a large – scale industrial complex, it can communicate with different types of control devices and upper – level management systems, enabling seamless data exchange and centralized control.

- Application Areas: The 369 – HI – R – M – F – E – 0 – 0 is used in manufacturing (automotive, aerospace, food processing), energy (power generation, oil and gas), and infrastructure (water treatment, transportation) industries.

- Application Case: In a water treatment plant, the 369 – HI – R – M – F – E – 0 – 0 was used to control the operation of pumps, valves, and chemical dosing systems. It received signals from water quality sensors and adjusted the equipment operation accordingly. After the installation of the 369 – HI – R – M – F – E – 0 – 0, the water treatment efficiency increased by [X]%, and the chemical consumption decreased by [X]% due to more precise control.

Compared to similar products in the market, the 369 – HI – R – M – F – E – 0 – 0 offers a higher level of reliability with a longer MTBF. Its flexible configuration options allow for more customized solutions, which is an advantage over some competitors with more rigid designs. The multiple communication interfaces provide better compatibility and integration capabilities, enabling it to be used in more complex industrial control networks.

- Compatibility: Ensure that the 369 – HI – R – M – F – E – 0 – 0 is compatible with your existing PLC system. Check the communication protocol, power supply requirements, and the number of input and output channels needed.

- Performance Requirements: Evaluate your requirements for reliability, flexibility, and communication capabilities. If your application requires long – term stable operation, customized control, and seamless system integration, the features of the 369 – HI – R – M – F – E – 0 – 0 are important.

- Installation Environment: Consider the temperature, humidity, vibration, and electromagnetic interference in the installation environment. The 369 – HI – R – M – F – E – 0 – 0 has a specified operating temperature range, and extreme conditions may require additional protective measures.

- Budget: Compare the cost of the 369 – HI – R – M – F – E – 0 – 0 with your budget. While it offers high – end features, consider the long – term benefits in terms of improved system performance and reduced maintenance costs.

- Installation: Follow the installation instructions carefully. Ensure proper grounding to prevent electrical interference. Connect the input and output signals correctly to avoid signal errors.

- Maintenance: Regularly check the module for any signs of damage or overheating. Clean the module to prevent dust accumulation, which may affect its performance.

- Safety: When working with the 369 – HI – R – M – F – E – 0 – 0, follow all safety procedures. Disconnect the power supply before performing any maintenance or repair work to avoid electric shock.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for 369 – HI – R – M – F – E – 0 – 0 and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide