Description

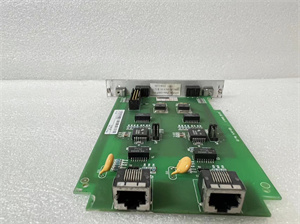

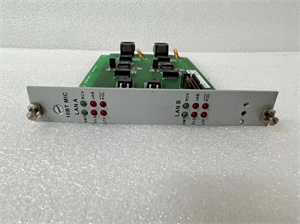

10BASE – T is an Ethernet technology that provides a reliable and efficient way for devices to communicate within a local area network. It is often used in PLC automation setups to enable seamless data transfer between different components such as PLC controllers, sensors, and actuators. The “10” in 10BASE – T represents the data transfer rate of 10 Mbps, which is sufficient for many typical automation applications to transmit control commands and receive feedback signals in a timely manner. The “BASE” indicates that it uses baseband signaling, and “T” stands for twisted pair, which means it uses unshielded twisted pair (UTP) cables for connection. One of the main advantages of 10BASE – T is its simplicity and wide compatibility. It allows for easy integration of various devices into a network, making it a popular choice for building cost – effective and flexible automation systems.

- Data Rate: 10 Mbps

- Cable Type: Unshielded Twisted Pair (UTP), usually Category 3 or higher

- Connector Type: RJ – 45

- Topology: Star topology is commonly used

- Maximum Segment Length: 100 meters

- High Reliability: With proper installation and cable quality, 10BASE – T can provide stable and reliable data transmission. In a manufacturing plant where an automation system has been using 10BASE – T for network communication, it has shown an uptime of over 99.5% in a year, with very few instances of data errors or communication failures.

- Easy Installation: The use of RJ – 45 connectors and UTP cables makes the installation process relatively simple. Even technicians with basic training can easily set up a 10BASE – T network.

- Cost – Effective: Compared to some higher – speed Ethernet standards, 10BASE – T requires less expensive equipment and cabling, making it a cost – effective solution for many applications where high data rates are not strictly necessary.

- Application Areas: 10BASE – T is widely used in various industries such as manufacturing, where it is used to connect PLCs, robots, and production line equipment for coordinated operation. In the energy sector, it can be used to monitor and control power distribution systems. In building automation, it is used to connect sensors, actuators, and control panels for managing lighting, heating, and ventilation systems.

- Application Case: In a food processing factory, 10BASE – T is used to connect all the PLC controllers that manage different production lines. These PLCs communicate with each other and with the central control system to ensure the smooth operation of the entire production process. For example, the filling machine’s PLC sends data about the filling volume and speed to the central control system via the 10BASE – T network, and the central control system can then adjust the production rate based on this information.

In comparison to some other higher – speed Ethernet standards, 10BASE – T may have a lower data transfer rate. However, for many traditional automation applications, the 10 Mbps rate of 10BASE – T is sufficient to meet the communication requirements without the need for the higher cost and complexity associated with faster standards. It offers a good balance between performance and cost, making it a preferred choice for applications where high – speed data transfer is not the top priority.

- Compatibility: When selecting 10BASE – T, make sure that all the devices in the network, such as PLCs, switches, and sensors, support this Ethernet standard to ensure seamless communication.

- Installation Environment: Consider the physical layout and environment of the installation. If the distance between devices is within 100 meters and the environment is not overly harsh in terms of electromagnetic interference, 10BASE – T is a suitable option.

- Budget: If the project has a limited budget, 10BASE – T can be a cost – effective solution as it requires less expensive equipment and cabling compared to some higher – end Ethernet technologies.

- Cable Installation: Follow the correct cable installation procedures to avoid signal interference and attenuation. Keep the cables away from power lines and other sources of electromagnetic interference.

- Connector Termination: Properly terminate the RJ – 45 connectors to ensure good electrical connections. Loose or poorly terminated connectors can lead to communication problems.

- Network Configuration: Configure the network settings correctly, including IP addresses and subnet masks, to ensure proper communication between devices.

- Maintenance: Regularly check the cables and connectors for any signs of damage or wear. Replace damaged components promptly to maintain the reliability of the network.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide 10BASE – T and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide