Description

FOXBORO FBM230 P0926GU Communication Module Detailed Explanation

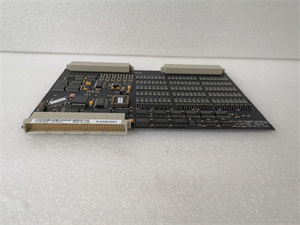

Product Overview

FOXBORO FBM230 P0926GU is a communication module used to connect field devices with Foxboro Evo systems.It provides a single Ethernet interface that enables single port field I/O devices to communicate with the Foxboro Evo system.This module plays an important role in the field of industrial automation,especially in process control systems.

Product Features

Multi port:Provides 4 serial ports,each port can be configured as RS-232,RS-422,or RS-485.

Flexible configuration:Supports multiple communication protocols and can be configured according to the protocols of on-site devices.

High reliability:Designed for industrial environments,it has high reliability and stability.

Easy to install:Modular design,easy to install.

Compatibility:Compatible with Foxboro Evo system.

Product parameters and specifications

Model:FBM230 P0926GU

Number of ports:4

Interface types:RS-232,RS-422,RS-485

Network interface:10/100Mbps Ethernet

Working temperature:-20℃~+70℃

Power supply voltage:24VDC

Installation method:DIN rail installation

Product series

FBM230 belongs to the Field Device System integrator(FDSI)module series of FOXBORO Evo system.

FBM230 P0926GU FOXBORO

Product function

Connect on-site devices:Connect on-site devices(such as transmitters,controllers,etc.)to the control system.

Data transmission:transmitting data between on-site devices and control systems.

Protocol conversion:Implementing the conversion between different protocols.

Product Usage

Process control:In a process control system,it is used to collect data from on-site equipment and transmit it to the control system.

Data collection:In a data collection system,it is used to collect on-site data for data analysis and processing.

Remote monitoring:It is possible to remotely monitor and configure on-site equipment through the network.

application area

Petrochemical industry:used to collect process variables such as temperature,pressure,flow rate,etc.,to achieve automated control of the production process.

Electricity:Used to collect operational parameters of power generation equipment,substations,and other devices.

Metallurgy:Used to collect various parameters during the smelting process and achieve automated control of the smelting process.

Water treatment:used to collect water quality parameters and achieve automated control of the water treatment process.

FBM230 P0926GU FOXBORO

summary

FOXBORO FBM230 P0926GU is a powerful communication module that has a wide range of applications in the field of industrial automation.It can connect various on-site devices to the control system,achieve data collection and transmission,thereby improving production efficiency and product quality.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide