Description

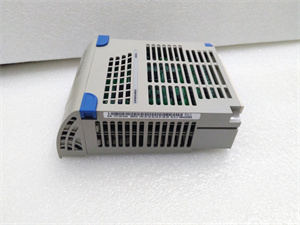

Emerson VE3005 MD Controller

The Emerson VE3005 is a high-performance MD Controller designed for Emerson’s DeltaV™ distributed control system (DCS), delivering advanced process control and automation capabilities for mission-critical industrial applications. Engineered to integrate seamlessly with DeltaV™ ecosystems, the VE3005 ensures reliable, scalable, and secure operation in harsh environments, making it ideal for industries such as oil & gas, power generation, and chemical processing.

1. Product Description

The Emerson VE3005 serves as the central processing unit (CPU) for DeltaV™ systems, enabling real-time monitoring, control logic execution, and data management across complex industrial processes. With support for up to 1,000 I/O points (a mix of analog and digital signals), it processes control algorithms at 500 MHz using a robust ARM Cortex-A9 processor, ensuring rapid response to process changes. The controller features dual redundant 24 VDC power supplies to minimize downtime in critical operations, along with a compact NEMA 4X/IP66-rated enclosure that withstands extreme temperatures (-40°C to 70°C) and environmental hazards.

The VE3005 supports multiple communication protocols, including Modbus RTU, HART, and Profibus DP, allowing seamless integration with third-party devices and legacy systems. Its hot-swappable design enables maintenance without system shutdown, while built-in cybersecurity features (such as encryption and firewall protection) safeguard against industrial cyber threats. Whether deployed in standalone setups or large-scale distributed networks, the VE3005 provides the reliability and performance needed to optimize process efficiency and safety.

2. Technical Specifications

| Parameter | Value |

|---|---|

| Processor | 500 MHz ARM Cortex-A9 |

| Memory | 512 MB RAM, 1 GB flash storage |

| I/O Capacity | Up to 1,000 points (configurable for analog/digital signals) |

| Power Supply | Dual redundant 24 VDC (18–32 VDC input range) |

| Communication Protocols | Modbus RTU, HART, Profibus DP, Ethernet/IP |

| Operating Temperature | -40°C to 70°C |

| Humidity Resistance | 0–95% RH (non-condensing) |

| Enclosure Rating | NEMA 4X/IP66 (suitable for indoor/outdoor use) |

| Dimensions | 144 mm × 60 mm × 30 mm (W × H × D) |

| Weight | 1.5 kg |

| Mounting Options | DIN rail or panel-mount |

| Compatibility | Emerson DeltaV™ DCS, AMS Device Manager, third-party field devices |

VE3005

3. Key Advantages and Features

- High Availability and Redundancy:

Dual redundant power supplies and hot-swappable components ensure continuous operation, with a mean time between failures (MTBF) exceeding 100,000 hours. A European chemical plant achieved zero unplanned downtime for 18 months using redundant VE3005 controllers in its reactor safety system. - Scalable Architecture:

Supports incremental expansion via DeltaV™ I/O modules (e.g., analog output modules for valve control or digital input modules for sensor integration), making it suitable for both small-scale setups and large industrial complexes. - Rugged Environmental Performance:

Operates reliably in extreme temperatures (-40°C to 70°C) and high-vibration environments, outperforming standard controllers that typically fail above 50°C. This makes it ideal for offshore platforms, arctic power plants, and desert refineries. - Advanced Cybersecurity:

Built-in security protocols protect against unauthorized access and data breaches, a critical feature for industries adhering to strict cybersecurity standards (e.g., IEC 62443). - Energy-Efficient Design:

Low power consumption (≤15 W) and intelligent sleep modes reduce energy costs by up to 20% compared to legacy controllers, without compromising performance.

4. Application Areas and Case Studies

Industry Applications

- Oil & Gas: Manages subsea wellhead controls, LNG liquefaction processes, and pipeline pressure regulation.

- Power Generation: Controls steam turbine speed, boiler combustion, and grid synchronization in thermal and renewable energy plants.

- Chemical Processing: Optimizes batch reactor temperatures, distillation column flows, and safety interlock systems.

- Water/Wastewater Treatment: Monitors pump speeds, chemical dosing, and quality control in large-scale treatment facilities.

Case Study

A North American LNG export terminal deployed VE3005 controllers to manage its cryogenic processing units. The controllers’ wide temperature tolerance (-40°C) and redundant architecture ensured stable operation during harsh winters, reducing downtime by 25% and improving throughput by 18%. The integration of Modbus RTU allowed seamless communication with third-party flow meters and safety valves, streamlining system management and reducing integration costs by 30%.

5. Competitor Comparison

The Emerson VE3005 distinguishes itself from comparable DCS controllers in:

- Temperature Resilience: Offers a -40°C to 70°C operating range, 40% wider than most alternatives (typically -20°C to 60°C), making it suitable for the most extreme industrial environments.

- Security Features: Embeds native cybersecurity protections, eliminating the need for add-on security modules that increase complexity and cost.

- Scalability: Supports up to 1,000 I/O points in a single controller, 25% more than standard models, enabling higher control density in compact spaces.

- Redundancy Design: Dual power supplies come as standard, whereas many competitors offer redundancy as a costly optional feature.

VE3005

6. Selection Recommendations

- System Compatibility:

Ensure the VE3005 aligns with your existing DeltaV™ system version and network infrastructure. Verify that field devices support the controller’s communication protocols (e.g., Profibus DP for legacy equipment). - Environmental Requirements:

Choose the VE3005 for outdoor, high-temperature, or high-humidity environments. For indoor use in controlled climates, assess if non-redundant models (with similar specs but lower cost) meet your needs. - Redundancy Needs:

Deploy dual VE3005 controllers for critical processes (e.g., safety instrumented systems) to achieve fault tolerance. For non-critical applications, a single controller may suffice to optimize costs. - Future Scalability:

If planning to expand your system, prioritize the VE3005’s high I/O capacity and modular design to avoid costly upgrades later.

7. Usage Precautions

- Installation:

- Mount the controller in a well-ventilated, grounded enclosure to dissipate heat and reduce electromagnetic interference (EMI).

- Use shielded cables for signal connections and separate power cables from data cables by at least 10 cm to minimize noise.

- Maintenance:

- Regularly inspect power supply connections and enclosure seals, especially in corrosive or dusty environments.

- Update firmware quarterly using Emerson’s AMS Device Manager to ensure compatibility with the latest DeltaV™ software and security patches.

- Safety:

- Power down the system before installing or replacing the controller, even though it supports hot-swapping, to prevent electrical hazards.

- Follow local safety codes for grounding (≤10 Ω) and ensure all wiring complies with NEC/NFPA standards.

- Spare Parts Management:

Keep at least one spare VE3005 on site for critical systems to minimize downtime during unexpected failures.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for Emerson VE3005 and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide