Description

The

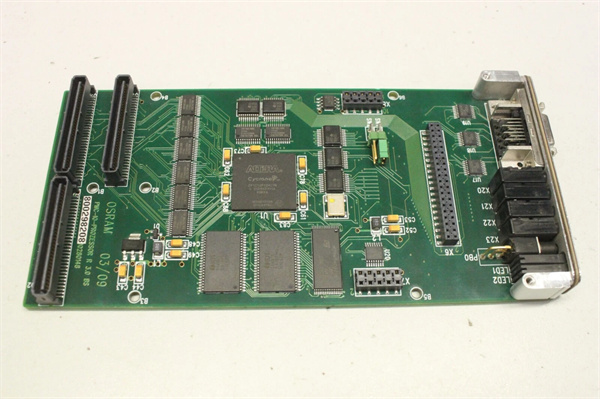

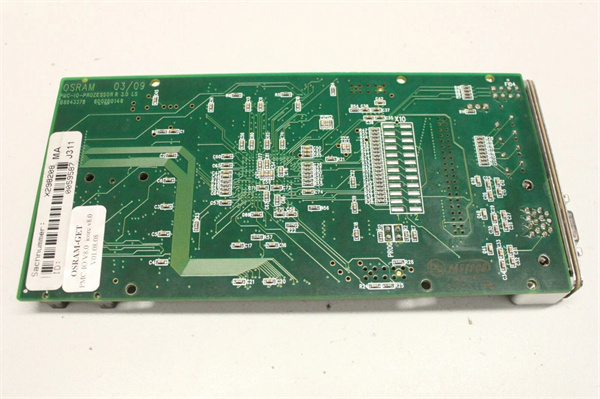

EMERSON PMC-IO-PROZESSOR serves as a key interface between the programmable logic controller (PLC) and input – output (IO) devices. It efficiently processes and transfers data between the control system and various field – level equipment, enabling seamless communication and precise control. With its advanced technology, the PMC – IO – PROZESSOR can handle multiple IO signals simultaneously, ensuring high – speed and reliable data processing. This allows for accurate monitoring and control of industrial processes, enhancing overall system performance. It is widely used in industrial automation scenarios to improve production efficiency, quality, and reliability. One of its significant advantages is its high compatibility, which can work smoothly with a variety of EMERSON – brand PLCs and other related equipment, reducing the complexity of system integration.

- Voltage: Usually operates at a standard industrial voltage, such as 24V DC or 110V/220V AC.

- Current: The rated current is designed to meet the power – consumption requirements of different application scenarios, generally within the range of 0.5A to 2A.

- Interface Type: It is equipped with common industrial – standard interfaces, such as RS – 485, Ethernet, and Profibus, to ensure convenient connection with other devices.

- Compatibility: Compatible with a series of EMERSON – brand PLCs and relevant control systems, and can also communicate with some third – party devices that comply with the corresponding protocols.

EMERSON PMC-IO-PROZESSOR

The PMC – IO – PROZESSOR stands out for its high reliability. It adopts redundant design and advanced error – correction technology, which can continuously and stably operate in harsh industrial environments, with a mean time between failures (MTBF) of up to 100,000 hours. In terms of easy integration, it has a standardized interface and communication protocol, which can be quickly and easily integrated into existing automation control systems, saving a lot of installation and commissioning time. For example, in a certain factory’s automation transformation project, the integration of the PMC – IO – PROZESSOR only took two days, which is 30% shorter than the original plan.

This spare part is suitable for a variety of industries, including manufacturing, energy, chemical, and food processing. In the manufacturing industry, it is used to control the production line equipment, realize the automation of the production process, and improve production efficiency and product quality. For example, a well – known automobile manufacturing enterprise uses the EMERSON PMC – IO – PROZESSOR in its assembly line control system to accurately control the operation of robots and conveyor belts, realizing the precise docking of each process and reducing the defect rate of products by 20%.

Compared with similar products in the market, the EMERSON PMC – IO – PROZESSOR has more excellent compatibility and stability. It can adapt to a variety of complex industrial environments and has stronger anti – interference ability. At the same time, its data – processing speed is faster, which can meet the requirements of high – speed production lines, helping users improve production efficiency and reduce production costs.

EMERSON PMC-IO-PROZESSOR

When selecting the EMERSON PMC – IO – PROZESSOR, users should first consider the compatibility with the existing control system to ensure seamless connection and normal operation. Secondly, the installation environment should be taken into account. If it is in a harsh environment with high temperature, high humidity, or strong electromagnetic interference, corresponding protective measures need to be taken. In addition, the budget is also an important factor. Although the product has excellent performance, users need to choose according to their actual economic strength to ensure cost – effectiveness.

During installation, it is necessary to strictly follow the installation instructions to ensure correct wiring and grounding to avoid electric shock and equipment damage. In the process of use, regular maintenance and inspection should be carried out to clean the dust and check the connection status of the equipment to ensure its stable operation. At the same time, it is necessary to back up the data in the device regularly to prevent data loss caused by equipment failure.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of [EMERSON PMC – IO – PROZESSOR] and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide