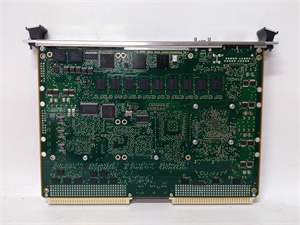

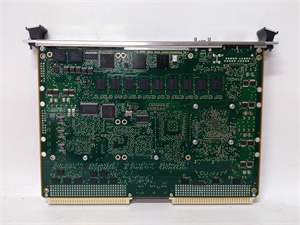

Description

The EMERSON MVME7100 is a high-performance embedded computing module designed to deliver reliable and efficient control solutions for industrial automation systems. As a key component of Emerson’s MVME series, the MVME7100 is engineered to meet the demanding requirements of harsh industrial environments, providing seamless integration with existing control architectures. This module serves as a versatile platform for data processing, communication, and real-time control, making it an ideal choice for applications that require robust computing power and stability.

The MVME7100 stands out for its ability to handle complex control algorithms while maintaining low power consumption, ensuring optimal performance in both standalone and networked setups. Its compact design and flexible configuration options allow for easy installation in various industrial settings, from manufacturing plants to energy production facilities. By combining advanced processing capabilities with rugged construction, the MVME7100 empowers users to enhance system reliability and operational efficiency.

| Parameter |

Specification |

| Processor |

PowerPC 750 (G4) CPU, up to 1.0 GHz |

| Memory |

512 MB DDR2 RAM (expandable up to 1 GB) |

| Storage |

256 MB Flash memory (support for SD card) |

| Power Supply |

24 V DC (range: 18–36 V DC) |

| Power Consumption |

Typical: 15 W; Maximum: 20 W |

| Operating Temperature |

-40°C to +85°C (extended industrial range) |

| Communication Interfaces |

Ethernet (10/100/1000 Mbps), RS-232/485, USB 2.0 |

| Form Factor |

3U CompactPCI Single Board Computer (SBC) |

| Compatibility |

Supports VxWorks, Linux, and Windows Embedded OS |

MVME7100

The EMERSON MVME7100 offers several distinct advantages that set it apart in industrial computing:

- High Reliability: Built with industrial-grade components, the module is tested to withstand extreme temperatures, vibrations, and electromagnetic interference, ensuring consistent performance in harsh environments.

- Powerful Processing: The PowerPC 750 CPU enables fast data processing and real-time control, capable of managing up to 1,000 I/O operations per second with minimal latency.

- Flexible Connectivity: Multiple communication interfaces allow seamless integration with sensors, actuators, and other control devices, supporting protocols like Modbus, Profibus, and Ethernet/IP.

- Energy Efficiency: Advanced power management features reduce energy consumption by up to 30% compared to legacy models, contributing to lower operational costs.

- Easy Maintenance: Hot-swappable design and remote diagnostics simplify troubleshooting, minimizing downtime during system upgrades or repairs.

The MVME7100 is widely used in industries that require precise and reliable control, including:

- Manufacturing: Machine automation, production line control, and quality monitoring.

- Energy: Power plant control, renewable energy systems, and substation automation.

- Process Control: Chemical and petrochemical plants, water treatment facilities, and industrial boilers.

Case Study: A leading automotive manufacturer integrated the MVME7100 into their assembly line control system to manage robotic arms and conveyor belts. The module’s high-speed processing and rugged design enabled real-time coordination of 50+ devices, reducing cycle times by 15% and improving system uptime to 99.9%.

When compared to similar industrial computing modules, the MVME7100 distinguishes itself through:

- Broader Temperature Range: Supports operation in temperatures 10–15°C wider than many alternatives, making it suitable for extreme environments.

- Higher Memory Capacity: Offers up to 1 GB RAM, enabling more complex control algorithms without performance degradation.

- Enhanced Network Security: Built-in hardware encryption protects data transmission, addressing growing cybersecurity needs in industrial applications.

MVME7100

When choosing the EMERSON MVME7100 or similar modules, consider the following:

- Compatibility: Ensure the module supports your existing software platform (e.g., VxWorks, Linux) and communication protocols.

- Environmental Requirements: Verify the operating temperature, humidity, and vibration resistance to match your installation environment.

- Performance Needs: Assess processing speed and memory capacity based on the complexity of your control tasks (e.g., simple I/O vs. advanced analytics).

- Scalability: Check for expandable storage and interface options if future system upgrades are planned.

To ensure optimal performance and safety when using the MVME7100:

- Electrostatic Discharge (ESD) Protection: Use anti-static wrist straps and mats during installation to prevent component damage.

- Power Supply Stability: Connect to a regulated power source within the specified voltage range to avoid voltage fluctuations.

- Cooling Requirements: Ensure adequate airflow in the installation enclosure, especially in high-temperature environments, to prevent overheating.

- Software Updates: Regularly install firmware updates from Emerson to access the latest features and security patches.

- Documentation Review: Consult the official user manual for detailed wiring diagrams and configuration guidelines before installation.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide