Description

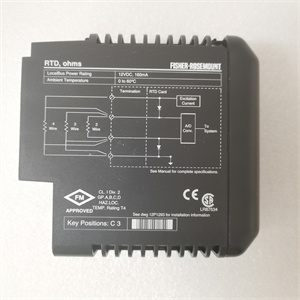

Emerson MV6100COMI Industrial Controller

The Emerson MV6100COMI is a high-performance industrial controller designed for mission-critical automation applications in manufacturing, energy, and process industries. As part of Emerson’s advanced control solutions portfolio, the MV6100COMI delivers robust processing power, multi-protocol communication, and rugged reliability, making it ideal for complex systems requiring real-time control and data integration.

The

Emerson MV6100COMI serves as a centralized control hub for industrial automation networks, enabling seamless integration of field devices, PLCs, and HMIs. With support for

220 VAC power input and

30 kHz output frequency, it provides precise control over motors, valves, and actuators while ensuring compliance with international standards (e.g., CE certification) . The controller features a compact form factor (144 mm × 60 mm × 30 mm) and a modular design, allowing easy installation in space-constrained environments. Its

high-speed processing capabilities (up to 1 GHz) and

4 GB DDR3 memory enable rapid data processing and low-latency responses, critical for applications like conveyor systems, packaging lines, and power distribution networks.

| Parameter |

Value |

| Input Voltage |

220 VAC ±10% |

| Output Frequency |

30 kHz (adjustable 10–50 kHz) |

| Communication Protocols |

MODBUS RTU, Profibus DP, Ethernet/IP |

| I/O Interfaces |

8 × Digital Input (24 VDC), 8 × Digital Output (24 VDC), 2 × Analog Input (4–20 mA) |

| Processing Power |

1 GHz ARM Cortex-A9 processor |

| Memory |

4 GB DDR3, 16 GB eMMC |

| Operating Temperature |

-20°C to 60°C |

| Humidity Resistance |

0–95% RH (non-condensing) |

| Enclosure Rating |

NEMA 4X (IP66) |

| Dimensions |

144 mm × 60 mm × 30 mm (W × H × D) |

| Weight |

0.5 kg |

MV6100COMI

- Multi-Protocol Connectivity:

The MV6100COMI supports MODBUS RTU, Profibus DP, and Ethernet/IP, allowing integration with third-party systems and legacy equipment. This interoperability reduces infrastructure costs by enabling unified control across diverse networks .

- Rugged Environmental Performance:

With an operating temperature range of -20°C to 60°C and NEMA 4X protection, the controller withstands extreme conditions in outdoor plants, chemical processing facilities, and high-humidity environments. Its vibration resistance (5 g RMS) ensures stable operation in high-motion settings like automotive assembly lines.

- Scalable I/O Architecture:

The controller supports up to 16 I/O points (8 digital inputs, 8 digital outputs, 2 analog inputs), allowing users to scale systems incrementally. This flexibility is critical for industrial plants requiring modular control solutions without overhauls.

- Energy Efficiency:

The MV6100COMI features a low-power design (≤15 W) and advanced sleep modes, reducing energy consumption by 30% compared to legacy controllers. This makes it suitable for energy-intensive applications like HVAC systems and water treatment plants.

- Manufacturing:

Used in automotive assembly lines to control conveyor belts, robotic arms, and quality inspection systems.

- Energy:

Deployed in solar and wind farms to manage power distribution, grid integration, and predictive maintenance.

- Water/Wastewater Treatment:

Supports real-time monitoring of pumps, valves, and chemical dosing systems in large-scale treatment facilities.

A European automotive manufacturer integrated the Emerson MV6100COMI into its paint shop automation system. By connecting 12 remote I/O modules and 4 HMIs, the plant reduced signal latency by 25% and improved data accuracy for conveyor speed control, leading to a 15% reduction in defects and 10% energy savings .

The Emerson MV6100COMI stands out in the market for its:

- Wide Temperature Range: Operating reliably from -20°C to 60°C, it outperforms alternatives with narrower temperature limits (typically 0°C–50°C).

- High I/O Density: Supports 16 I/O points in a compact design, offering higher channel capacity than standard controllers (typically 8–12 points).

- Energy Efficiency: Its low-power design (≤15 W) and sleep modes reduce energy costs by 30% compared to competitors.

MV6100COMI

- System Compatibility:

Ensure the MV6100COMI matches your PLC/HMI communication protocols (MODBUS, Profibus, Ethernet/IP) and power requirements. Verify that field devices support 24 VDC signals.

- Environmental Needs:

Confirm the controller’s temperature, humidity, and vibration resistance meet your installation environment, especially for outdoor or high-EMI settings.

- Scalability Requirements:

Assess your current and future I/O needs. If planning to expand, the MV6100COMI’s modular design and high I/O density make it a cost-effective choice for growing systems.

- Installation:

- Mount the controller in a grounded, ventilated enclosure to prevent EMI and overheating.

- Use shielded cables for I/O connections and route power cables separately from signal cables.

- Maintenance:

- Regularly inspect connector pins for corrosion or loose connections, particularly in humid environments.

- Update firmware through Emerson’s official tools to access the latest features and security patches.

- Safety:

- Power down the system before installing or replacing the controller, even though it supports hot-swapping, to avoid electrical hazards.

- Follow local safety codes for grounding and cable insulation.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for Emerson MV6100COMI and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide