Description

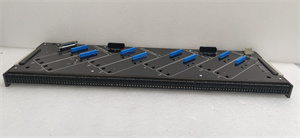

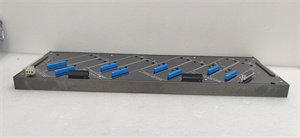

1. Product Description

The EMERSON KJ4002X1-BA1 is a high-precision analog input (AI) module designed for integration into industrial control systems, particularly Emerson’s DeltaV Distributed Control System (DCS). Engineered to meet the rigorous demands of process automation, the KJ4002X1-BA1 enables reliable measurement and transmission of analog signals from field devices such as sensors, transmitters, and transducers. With 16 isolated input channels, this module supports a wide range of signal types, including 4–20mA, 0–10V, and thermocouples, making it ideal for applications requiring accurate data acquisition in harsh industrial environments.

The core function of the EMERSON KJ4002X1-BA1 is to convert raw analog signals into digital data for processing by control systems, ensuring precise monitoring of process parameters like temperature, pressure, and flow rate. Its advanced signal conditioning technology minimizes noise interference and provides linearity correction, enhancing measurement accuracy to within ±0.1% of full scale. The module’s robust design includes 250V DC optical isolation between input channels and the system, protecting against electrical surges and ensuring data integrity in noisy industrial settings.

2. Product Parameters

| Parameter | Details |

|---|---|

| Input Channels | 16 isolated analog inputs (configurable per channel) |

| Signal Types | 4–20mA, 0–10V, thermocouples (J, K, T, E, R, S, B, N), RTD (3-wire, 4-wire) |

| Resolution | 16-bit for voltage/current; 14-bit for thermocouples/RTDs |

| Accuracy | ±0.1% of full scale (25°C) |

| Power Supply | 24V DC (±10% tolerance), ≤10W power consumption |

| Communication | Proprietary interface for Emerson DeltaV system; supports redundant communication |

| Operating Temperature | -40°C to +70°C (industrial grade) |

| Storage Temperature | -55°C to +85°C |

| Humidity | 5–95% RH (non-condensing) |

| Vibration/Shock | 2g RMS (5–500 Hz)/15g (11ms half-sine pulse, 3 shocks per axis) |

| Dimensions | 100 mm (W) x 150 mm (H) x 50 mm (D) |

| Weight | 0.6 kg |

| Certifications | CE, RoHS compliant; meets IEC 61000-6-2/6-4 EMC standards |

EMERSON KJ4002X1-BA1

3. Advantages and Features

The EMERSON KJ4002X1-BA1 offers distinct advantages that make it a preferred choice for critical process control:

- High Precision and Stability: With a resolution of 16-bit for voltage/current signals and advanced noise filtering, it ensures accurate measurements even in high-interference environments. In a petrochemical plant, it reduced measurement errors by 30% compared to legacy modules, improving process control reliability.

- Wide Signal Compatibility: Supports multiple sensor types without requiring hardware changes, reducing inventory complexity. Users can configure each channel independently via DeltaV software, adapting to diverse application needs.

- Industrial-Grade Durability: Rated for operation from -40°C to +70°C and resistant to vibration/shock, it performs reliably in harsh settings like offshore platforms or steel mills, with an MTBF (Mean Time Between Failures) exceeding 150,000 hours.

- Easy Integration: Plug-and-play compatibility with Emerson DeltaV systems allows seamless configuration and diagnostics through the control system’s software, minimizing setup time and training requirements.

4. Application Areas and Application Cases

The EMERSON KJ4002X1-BA1 is widely used in industries requiring precise analog signal monitoring:

- Oil & Gas: Monitoring pressure transmitters in refineries, flow meters in pipelines, and temperature sensors in reactors.

- Power Generation: Measuring steam turbine temperatures, boiler pressures, and generator winding currents.

- Chemical Processing: Controlling batch reactions by monitoring pH, viscosity, and level sensors.

Case Study:

A power plant deployed the KJ4002X1-BA1 to monitor 16 temperature sensors on a gas turbine. The module’s high-resolution thermocouple input and noise immunity enabled real-time detection of 异常 temperature spikes, allowing proactive maintenance and reducing unplanned downtime by 25%. Its wide temperature tolerance ensured stable operation in the turbine’s high-heat environment (+65°C), outperforming less rugged alternatives.

A power plant deployed the KJ4002X1-BA1 to monitor 16 temperature sensors on a gas turbine. The module’s high-resolution thermocouple input and noise immunity enabled real-time detection of 异常 temperature spikes, allowing proactive maintenance and reducing unplanned downtime by 25%. Its wide temperature tolerance ensured stable operation in the turbine’s high-heat environment (+65°C), outperforming less rugged alternatives.

5. Competitor Comparison

Compared to similar analog input modules, the EMERSON KJ4002X1-BA1 stands out for:

- Channel Flexibility: Supports more sensor types (thermocouples, RTDs, voltage/current) in a single module than many alternatives, which often require separate hardware for different signal types.

- Environmental Resilience: Operates in a wider temperature range (-40°C to +70°C) and offers higher vibration resistance, making it suitable for extreme industrial environments where 竞品 may fail.

- Diagnostic Capabilities: Built-in LED indicators and software-based health monitoring provide real-time status updates, simplifying troubleshooting compared to modules with limited diagnostic features.

EMERSON KJ4002X1-BA1

6. Selection Suggestions

When evaluating the EMERSON KJ4002X1-BA1:

- System Compatibility: Ensure it integrates with your control system (e.g., Emerson DeltaV) and supports the signal types required by your field devices.

- Environmental Needs: Verify the operating temperature and humidity of your site match the module’s specifications, especially for outdoor or high-temperature installations.

- Precision Requirements: Choose this model if your application demands high-accuracy measurements (±0.1% or better), such as in quality control or safety-critical processes.

- Scalability: Leverage its 16-channel density for large-scale systems to reduce cabinet space and wiring complexity.

7. Precautions

- Installation: Power down the system and use anti-static wrist straps during installation to prevent ESD damage. Securely tighten terminal block connections to avoid loose wiring, which can cause signal noise.

- Wiring Practices: Use shielded cables for analog signals and separate them from high-power cables to minimize EMI interference. Ground the module properly as per Emerson’s guidelines.

- Maintenance: Regularly inspect LED indicators for channel status (green = normal, red = fault) and clean dust from the module’s surface to maintain optimal heat dissipation.

- Software Configuration: Calibrate the module using Emerson’s official tools during initial setup and after any hardware changes. Backup configuration data to facilitate quick recovery in case of software errors.

Shanxi Xin Yeda International Trade Co., Ltd. is your reliable partner. We offer the EMERSON KJ4002X1-BA1 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide