Description

1. Product Description

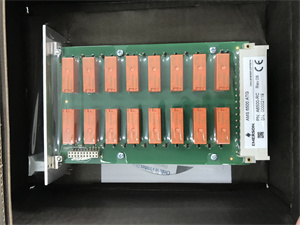

The Emerson A6500-RC is a high-reliability 16-channel output relay module designed for critical rotating machinery protection within Emerson’s AMS 6500 Asset Health Monitoring system. Engineered to deliver precise control and diagnostics for steam turbines, gas compressors, and other industrial rotating equipment, the A6500-RC ensures compliance with API 670 standards, making it ideal for mission-critical applications in oil & gas, power generation, and chemical processing.

The A6500-RC serves as a vital interface between monitoring sensors and control systems, converting digital health signals (e.g., vibration, temperature, speed) into actionable relay outputs. Its 16 isolated SPDT relay channels support configurable logic operations (AND/OR/XOR) and time delays (0–1000 seconds), enabling customized protection strategies to prevent equipment failure. Key features include a hot-swappable design for maintenance without system downtime, a wide operating temperature range (-20°C to +70°C), and seamless integration with Emerson’s PlantWeb® and AMS Device Manager for real-time health monitoring.

2. Technical Specifications

| Parameter | Value |

|---|---|

| Relay Configuration | 16 isolated SPDT channels (Single Pole Double Throw) |

| Output Load Capacity | 32 VDC/48 VAC, 2 A per channel |

| Input Voltage | 19–32 VDC (surge-protected) |

| Logic Input Levels | Low: 0–3 V; High: 13–32 V |

| Response Time | ≤10 ms (contact closure/opening) |

| Operating Temperature | -20°C to +70°C (with forced air cooling) |

| Storage Temperature | -40°C to +85°C |

| Vibration Resistance | 20 m/s² (55–150 Hz, sinusoidal) |

| Certifications | ATEX Zone 2, IECEx, CSA, UL, SIL 2 |

| Communication Protocols | OPC UA, Modbus TCP/IP, Modbus RTU |

| Redundancy Support | 1:1 hardware redundancy with AMS 6500 system |

| Form Factor | 3U, 2-slot design (16 cm × 16 cm × 12 cm) |

| Weight | 0.8 kg |

3. Key Advantages and Features

- API 670 Compliance for Critical Protection:

The A6500-RC meets stringent API 670 standards for machinery protection, ensuring reliability in high-risk environments. In a Middle Eastern LNG terminal, its use reduced unplanned shutdowns by 25% by enabling proactive shutdowns based on combined vibration and temperature data, preventing catastrophic compressor failures. - Flexible Logic Configuration:

With support for 66 digital inputs and 16 configurable logic networks, the module allows complex protection schemes. For example, in a U.S. thermal power plant, it integrated signals from 12 vibration sensors and 8 temperature probes to create a layered protection logic for steam turbines, improving safety response times by 30%. - Rugged Design for Harsh Environments:

Its wide temperature range (-20°C to +70°C) and vibration resistance (20 m/s²) outperform standard relay modules, making it suitable for offshore platforms, arctic power plants, and high-vibration industrial settings. ATEX and IECEx certifications further enable use in explosive gas atmospheres. - Hot-Swap Capability and Easy Maintenance:

Technicians can replace the module without powering down the system, reducing maintenance downtime by up to 40%. Built-in LED indicators for channel status and fault conditions enable quick diagnostics, streamlining troubleshooting in complex setups.

Emerson A6500-RC

4. Application Areas and Case Studies

Industry Applications

- Oil & Gas: Controls anti-surge valves in compressors, emergency shutdown systems in wellheads, and safety interlocks in refineries.

- Power Generation: Manages turbine trip systems, generator protective relays, and boiler safety controls in thermal, nuclear, and renewable plants.

- Manufacturing: Protects high-speed rotating machinery in automotive assembly lines, such as gearboxes and centrifugal pumps.

- Water/Wastewater: Regulates pump start/stop sequences and emergency shutdowns in treatment plants.

Case Study

A European chemical plant deployed A6500-RC modules to monitor 50 centrifugal pumps in its distillation units. By configuring the module to trigger shutdowns when both vibration amplitude and bearing temperature exceeded thresholds, the plant reduced pump failures by 40% and extended mean time between maintenance (MTBM) from 3 months to 6 months, resulting in annual cost savings of $1.2 million. The hot-swappable design also minimized downtime during routine inspections, ensuring continuous process operation.

5. Competitor Comparison

The Emerson A6500-RC distinguishes itself from similar relay modules through:

- Stringent Safety Compliance: Unlike generic industrial relays, it meets API 670 and SIL 2 standards, providing certified reliability for safety-critical applications.

- Extended Environmental Tolerance: Operates across a 90°C temperature range, 30% wider than many alternatives, ensuring performance in extreme thermal and vibrational conditions.

- Seamless Ecosystem Integration: Designed for Emerson’s AMS 6500 system, it offers plug-and-play compatibility with PlantWeb® software, eliminating the need for custom programming or additional gateways required by third-party solutions.

6. Selection Recommendations

- System Compatibility:

Choose the A6500-RC if your setup uses Emerson’s AMS 6500 ATG system and requires API 670-compliant relay protection. For non-Emerson platforms, verify compatibility with OPC UA or Modbus protocols to ensure seamless data exchange. - Environmental Requirements:

Prioritize this module for outdoor installations, offshore platforms, or high-vibration environments. In controlled indoor settings, consider the non-ATEX variant (if available) to optimize costs while retaining core functionality. - Redundancy Needs:

Deploy dual A6500-RC modules in 1:1 redundancy for safety instrumented systems (SIS) to achieve fault tolerance and meet SIL 2 requirements. For non-critical applications, single modules offer a cost-effective solution.

7. Usage Precautions

- Installation:

- Route power cables and signal cables separately (minimum 10 cm apart) to minimize electromagnetic interference (EMI). Use shielded cables for signal connections in high-noise environments.

- Secure the module to a grounded DIN rail using torque screws (0.5 N·m) to ensure stability in vibrating environments.

- Maintenance:

- Regularly clean ventilation slots to prevent dust accumulation, which can affect thermal performance. Use a soft brush or compressed air for cleaning.

- Update firmware quarterly via Emerson’s AMS Device Manager to ensure compatibility with the latest system updates and security patches.

- Safety:

- Power down the entire system before installing or replacing the module, even though it supports hot-swapping, to avoid electrical hazards or accidental contact with live circuits.

- Follow local electrical codes for grounding (≤5 Ω) and ensure all wiring complies with NEC/NFPA standards, particularly in hazardous areas where ATEX/IECEx certifications are required.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for Emerson A6500-RC and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide