Description

1. Product Description

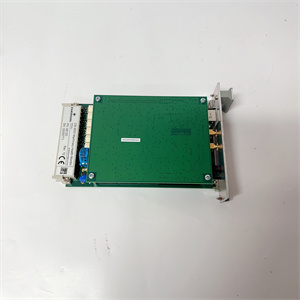

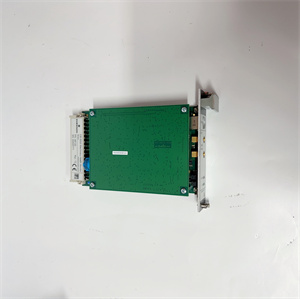

The Emerson A6120 9199-00002 is a highly efficient dual-channel vibration and position monitoring module. This module is a crucial component in industrial machinery health management systems.

The core function of the A6120 9199-00002 is to precisely monitor the vibration and position of industrial equipment. It can convert the physical signals related to vibration and position into electrical signals for further processing and analysis. By continuously monitoring these parameters, it enables early detection of potential equipment failures, such as unbalance, misalignment, or bearing wear. This module is designed to meet the strict requirements of industrial applications, especially in scenarios where the reliability of rotating machinery is of utmost importance.

The A6120 9199-00002 is used in various industrial settings to ensure the smooth operation of equipment. Its advantages are numerous. It offers high accuracy in measurement, which is essential for identifying small but critical changes in equipment conditions. Additionally, it has a robust design that allows it to operate stably in harsh industrial environments, including high temperatures, high humidity, and strong electromagnetic interference. The module also features easy integration with existing control systems, reducing the complexity of system setup and maintenance.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 18 – 31 VDC (nominal 24 VDC) |

| Input Voltage Range | – 5 to + 15 VDC |

| Communication Interface | 3-way RS232 or 485 serial port |

| Serial Port Rate | 300 – 9600 bps |

| Operating Temperature | – 20 °C to 70 °C |

| Operating Humidity | ≤ 95% non-condensing, non-corrosive, non-explosive environment |

| Power Consumption | Standby: 1 W, Transmit: 2 W |

| Relay Output | Slots for 16 or 32 shutdown relay outputs, configurable relay bypass and trip magnification per channel |

| Compatibility | Compatible with various industrial control systems and can communicate with third-party devices through redundant Modbus, TCP, or serial ports |

Emerson A6120 9199-00002

3. Advantages and Characteristics

- High Reliability: The A6120 9199-00002 has a mean time between failures (MTBF) of over 100,000 hours. In a large petrochemical plant, it has been operating continuously for more than 3 years without any major failures, ensuring the stable monitoring of compressors’ vibration and position.

- Easy Integration: In a manufacturing plant’s upgrade project, the A6120 9199-00002 was integrated into the existing control system within just one day. Its multiple communication interfaces, such as RS232 and RS485, and support for common protocols like Modbus and TCP, make it easy to connect with different devices and systems.

- Accurate Measurement: With its advanced sensor technology, it can measure vibration amplitudes with an accuracy of ±0.1%. This high level of accuracy helps in detecting even the slightest changes in equipment conditions, allowing for timely maintenance actions.

4. Application Areas and Application Cases

- Application Areas: The A6120 9199-00002 is widely used in industries such as power generation, oil and gas, manufacturing, and chemical processing. It is suitable for monitoring the vibration and position of various rotating machinery, including steam turbines, gas turbines, pumps, and fans.

- Application Case: In a power generation plant, the A6120 9199-00002 was installed on a steam turbine. Through continuous monitoring of the turbine’s vibration and position, the maintenance team was able to detect a slight misalignment in the rotor. By taking timely corrective actions, they prevented a potential major failure of the turbine, which could have resulted in a production shutdown lasting for several days. This not only saved a significant amount of money but also ensured the stable power supply to the grid.

5. Competitive Comparison

Compared to similar products in the market, the A6120 9199-00002 offers better accuracy in measurement, with a higher resolution in detecting vibration and position changes. It also has a more extensive operating temperature range, making it suitable for a wider variety of industrial environments. Its communication interfaces are more diverse and flexible, allowing for easier integration with different control systems and devices. Moreover, its robust design and high MTBF make it more reliable in long-term operation, reducing the need for frequent replacements and maintenance.

Emerson A6120 9199-00002

6. Selection Recommendations

- Compatibility: When selecting the A6120 9199-00002, ensure that it is compatible with your existing control system. Check the communication protocols and interface types to ensure seamless integration. Also, verify if it can communicate with the sensors and other devices you plan to use.

- Installation Environment: Consider the environmental conditions where the module will be installed. If it is in a harsh environment with high temperatures, humidity, or electromagnetic interference, ensure that the module’s specifications can withstand such conditions. For example, if the installation site has a high temperature, make sure the module’s operating temperature range can cover it.

- Budget: While the A6120 9199-00002 offers excellent performance and reliability, it is important to consider your budget. Compare the prices of different suppliers and also factor in the long-term costs, such as maintenance and potential replacements. Sometimes, investing a bit more in a high-quality module can save you more in the long run due to its reliability and lower maintenance requirements.

7. Precautions

- Installation: When installing the A6120 9199-00002, follow the installation instructions carefully. Ensure that the power supply is within the specified range and that all connections are secure. Use proper shielding for cables to prevent electromagnetic interference.

- Maintenance: Regularly check the module’s operating status, including its power consumption and communication performance. Clean the module periodically to remove dust and debris, which can affect its performance. If any issues are detected, refer to the user manual or contact the manufacturer’s technical support for assistance.

- Safety: Ensure that the installation and operation of the module comply with all relevant safety regulations. Do not attempt to open the module or perform any repairs without proper authorization, as this may pose a safety risk.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of [Emerson A6120 9199-00002] and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide