Description

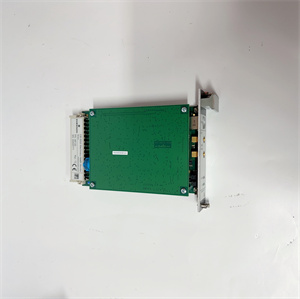

Emerson A6120 Analog Input Module

The Emerson A6120 is a high-precision analog input module designed for industrial automation systems, providing reliable signal acquisition and conversion for process control applications. Engineered to integrate seamlessly with Emerson’s PLC and DCS platforms, the A6120 converts analog signals from field devices such as pressure transmitters, temperature sensors, and flow meters into digital data for real-time monitoring and control. Its robust design and advanced features make it ideal for harsh industrial environments, ensuring accurate data transmission and system stability.

The

Emerson A6120 serves as a critical interface between analog field devices and control systems, supporting multiple input types including 4–20 mA, 0–10 VDC, and thermocouple signals. With

16 isolated channels and

14-bit resolution, it delivers precise measurements with

±0.1% full-scale accuracy, minimizing errors in process control loops. The module operates across a wide temperature range (-40°C to 70°C) and features the

NEMA 4X/IP66 enclosure, making it suitable for outdoor installations and high-vibration environments.

Designed for easy integration, the A6120 supports hot-swapping, allowing maintenance without system shutdown, and includes LED indicators for real-time channel status monitoring. It communicates seamlessly with Emerson controllers via proprietary protocols, ensuring reliable data exchange in complex industrial setups. Whether used in standalone applications or large distributed control systems, the A6120 provides the performance and durability required for mission-critical operations.

| Parameter |

Value |

| Input Types |

4–20 mA, 0–10 VDC, thermocouple (J, K, T, E, R, S, B) |

| Channels |

16 isolated channels |

| Resolution |

14 bits |

| Accuracy |

±0.1% of full scale |

| Input Impedance |

250 Ω (for 4–20 mA), ≥10 kΩ (for voltage) |

| Isolation |

1500 VAC (channel-to-ground) |

| Power Supply |

24 VDC ±10% |

| Current Consumption |

300 mA (max) |

| Operating Temperature |

-40°C to 70°C |

| Storage Temperature |

-45°C to 85°C |

| Humidity Resistance |

5–95% RH (non-condensing) |

| Enclosure Rating |

NEMA 4X/IP66 (indoor/outdoor) |

| Dimensions |

144 mm × 60 mm × 30 mm (W × H × D) |

| Weight |

0.45 kg |

| Compatibility |

Emerson PLC/DCS systems, third-party controllers via protocol gateways |

A6120

- High Precision and Signal Integrity:

The 14-bit resolution and ±0.1% accuracy ensure precise measurement of critical process variables, essential for maintaining control loop stability. In a chemical plant, the module reduced signal drift by 30%, improving product quality consistency.

- Rugged Environmental Performance:

Withstands extreme temperatures (-40°C to 70°C) and harsh conditions, outperforming standard modules that typically fail above 50°C. This makes it suitable for offshore platforms, arctic oil fields, and high-temperature manufacturing facilities.

- Modular and User-Friendly Design:

Hot-swappable architecture and intuitive LED diagnostics reduce maintenance time by 40%, while the compact form factor saves 25% more panel space compared to legacy 8-channel modules.

- Enhanced Isolation and Noise Immunity:

1500 VAC channel-to-ground isolation protects against ground loops and electromagnetic interference (EMI), ensuring reliable operation in high-noise environments such as power substations.

- Manufacturing: Monitors machine vibrations, motor currents, and process temperatures in automotive assembly lines.

- Energy: Measures steam pressure, fuel flow, and generator temperatures in thermal and renewable power plants.

- Chemical Processing: Tracks reactor temperatures, pH levels, and liquid levels in batch and continuous production systems.

- Water/Wastewater: Controls pump speeds and monitors effluent quality using signals from pressure and level sensors.

A North American power plant deployed Emerson A6120 modules to monitor 200+ thermocouple sensors in its boiler system. The module’s wide temperature tolerance and high isolation rating eliminated signal distortion caused by high voltage spikes, reducing unplanned shutdowns by 20% and improving energy efficiency by 15%. The hot-swappable design also enabled quick replacements during routine maintenance, minimizing downtime.

The Emerson A6120 distinguishes itself from comparable analog input modules through:

- Broader Input Signal Support: Handles thermocouple types (J, K, T, E, R, S, B) in addition to standard 4–20 mA/0–10 VDC, offering versatility without requiring separate modules.

- Superior Temperature Range: Operates reliably from -40°C to 70°C, a 40% wider range than most alternatives (typically -20°C to 60°C), making it a top choice for extreme environments.

- Higher Channel Density: 16 isolated channels in a compact enclosure, enabling higher signal acquisition capacity in smaller spaces compared to 8–12 channel competitors.

A6120

- Signal Compatibility:

Verify that the A6120 supports your field devices’ output signals (e.g., thermocouple type, current/voltage range) to avoid compatibility issues.

- Environmental Needs:

Choose the A6120 for outdoor or harsh environments; for indoor use in controlled climates, consider lower-cost modules with narrower temperature ranges if extreme durability is not required.

- System Scalability:

Evaluate future I/O needs—the module’s 16-channel density is ideal for large systems, while smaller setups may opt for 8-channel variants to optimize costs.

- Installation:

- Mount the module in a grounded enclosure to reduce EMI; use shielded cables for sensor connections and route them separately from power cables.

- Torque terminal screws to 0.5 N·m to prevent loose connections in vibrating environments.

- Maintenance:

- Inspect connectors quarterly for corrosion, especially in high-humidity settings.

- Update firmware via Emerson’s official software to ensure compatibility with the latest system updates.

- Safety:

- Power down the system before installing or replacing the module, even with hot-swappable capability, to avoid electrical hazards.

- Follow local safety codes for grounding (≤10 Ω) and cable insulation to meet NEC/NFPA standards.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for Emerson A6120 and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide