Description

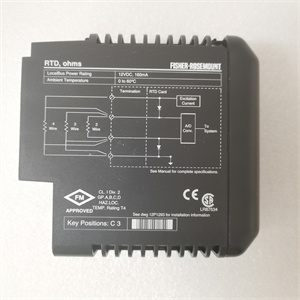

Emerson 1C31205G01 Remote Node Controller Base

The Emerson 1C31205G01 is a robust remote node controller base designed for Emerson’s Ovation™ distributed control system (DCS), enabling scalable and reliable expansion of industrial automation networks. As a critical component for distributed I/O systems, the 1C31205G01 facilitates seamless communication between field devices and central controllers, making it ideal for large-scale applications in power generation, oil & gas, and water treatment.

The

Emerson 1C31205G01 serves as the foundation for remote I/O nodes in Ovation™ systems, supporting up to two remote node modules and connecting with multiple I/O branches. It features a user-friendly rotary switch for node addressing (0–15) and a D-connector that links to up to six I/O branches, allowing flexible system configuration. This module is engineered to thrive in harsh industrial environments, with a wide operating temperature range (-40°C to 70°C) and rugged construction that withstands vibration and electromagnetic interference (EMI). By enabling decentralized control, the

1C31205G01 enhances system scalability, reduces cabling complexity, and ensures stable data transmission in distributed control setups.

| Parameter |

Value |

| Input Voltage |

24 VDC ±10% |

| Node Addressing |

Rotary switch (0–15, 16 possible addresses) |

| I/O Interfaces |

1 x D-connector for up to 6 I/O branches |

| Compatibility |

Emerson Ovation™ DCS, MODBUS RTU for third-party systems |

| Operating Temperature |

-40°C to 70°C |

| Storage Temperature |

-55°C to 85°C |

| Humidity Resistance |

0–95% RH (non-condensing) |

| Vibration Resistance |

0.05 g RMS (5–500 Hz) |

| Shock Resistance |

15 g (11 ms half-sine pulse) |

| Dimensions |

144 mm × 60 mm × 30 mm (W × H × D) |

| Weight |

0.3 kg |

1C31205G01

-

Scalable I/O Architecture:

The 1C31205G01 supports expansion with up to six I/O branches and two remote node modules, allowing users to scale systems incrementally as operational needs grow. This flexibility is crucial for large industrial plants requiring modular control solutions.

-

Harsh Environment Reliability:

With an operating temperature range of -40°C to 70°C and robust EMI/RFI protection, the module performs reliably in extreme conditions, such as offshore platforms, power plant boiler rooms, or arctic installations. Its shock and vibration resistance ensures stable operation in high-motion environments.

-

Seamless System Integration:

Designed for native compatibility with Ovation™ controllers, the 1C31205G01 minimizes engineering effort by eliminating the need for custom interfaces. It also supports MODBUS RTU, enabling integration with third-party monitoring systems for unified control.

-

Hot-Swappable Design:

The module can be replaced or serviced without powering down the system, reducing downtime during maintenance. This feature is critical for mission-critical applications where continuous operation is essential.

- Power Generation:

Used in thermal and nuclear power plants to manage remote I/O for turbine sensors, boiler valves, and auxiliary systems, ensuring real-time data exchange between field devices and central control rooms.

- Oil & Gas:

Deployed in refineries and offshore platforms to connect distributed sensors and actuators in pipeline networks, compressor stations, and production units.

- Water/Wastewater Treatment:

Supports remote monitoring of pumps, level sensors, and chemical dosing systems in large-scale treatment facilities, enabling centralized control of decentralized processes.

A North American natural gas processing plant integrated the Emerson 1C31205G01 to expand its Ovation™ system across multiple production lines. By connecting 12 remote I/O branches, the plant reduced cabling costs by 30% and improved data transmission speed by 25%, leading to more precise control of gas compressors and a 15% reduction in unplanned downtime.

The Emerson 1C31205G01 stands out in the market for its:

- Extreme Temperature Performance: Operating reliably from -40°C to 70°C, it outperforms many alternatives that are limited to narrower temperature ranges.

- High Scalability: Supporting up to six I/O branches, it offers greater expansion capacity than standard remote node bases, which typically support 2–4 branches.

- Native System Integration: Its seamless compatibility with Ovation™ software and hardware reduces integration time and debugging efforts compared to non-native solutions.

1C31205G01

- System Compatibility:

Ensure the 1C31205G01 matches your existing Ovation™ controller version and network architecture. Verify that your field devices and third-party systems (if used) are compatible with MODBUS RTU.

- Environmental Needs:

Confirm the module’s -40°C to 70°C temperature range and vibration resistance meet your installation environment, especially for outdoor or high-motion settings.

- Scalability Requirements:

Assess your current and future I/O needs. If planning to expand, the 1C31205G01’s support for multiple branches makes it a cost-effective choice for growing systems.

- Installation:

- Mount the module in a grounded, ventilated enclosure to prevent EMI and overheating.

- Use shielded cables for I/O connections to minimize signal interference, and route power and signal cables separately.

- Maintenance:

- Regularly inspect connector pins for corrosion or loose connections, especially in high-humidity environments.

- Update firmware through Emerson’s official tools to access the latest features and security patches.

- Safety:

- Power down the system before installing or replacing the module, even though it is hot-swappable, to avoid accidental electrical contact.

- Follow local safety codes for grounding and cable insulation to prevent electrical hazards.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for Emerson 1C31205G01 and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide