Description

Product Specification: ELAU MAX-4/11/03/128/08/1/1/00 Motion Controller

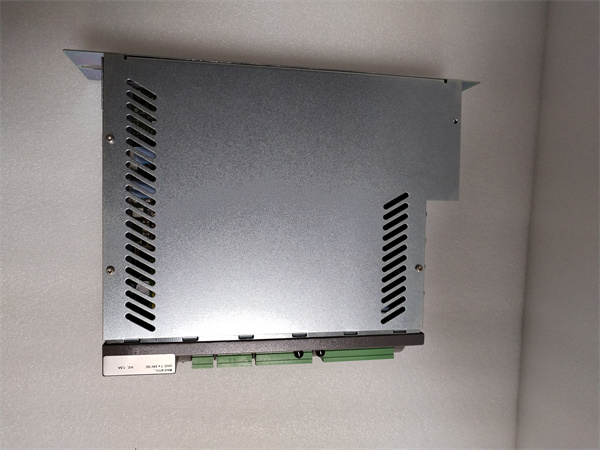

ELAU MAX-4/11/03/128/08/1/1/00 is a high-performance motion controller designed for industrial automation systems, offering advanced multi-axis synchronization and real-time control capabilities. Part of ELAU’s PACDrive series, this controller combines rugged reliability with modular flexibility, making it ideal for applications requiring precision and scalability.

The

MAX-4/11/03/128/08/1/1/00 integrates an industrial PC architecture with a VxWorks real-time operating system, enabling deterministic control of up to

40 servo axes via SERCOS fiber-optic bus. It supports multiple communication protocols (PROFIBUS DP, DeviceNet, Ethernet TCP/IP) and features built-in digital/analog I/O, touch probe inputs, and compact flash storage for data logging. With its intelligent diagnostics and OPC connectivity, the controller simplifies remote monitoring and reduces downtime.

| Parameter |

Specification |

| CPU |

ST-PC Vega |

| Memory |

128 MB RAM |

| Power Supply |

100–240 V AC, 50/60 Hz |

| Max. Servo Axes |

40 (via SERCOS) |

| Communication |

SERCOS III, PROFIBUS DP, DeviceNet |

| I/O Interfaces |

Digital I/O (128 in/64 out), analog I/O (8 in/8 out) |

| Dimensions |

215 mm × 215 mm × 50 mm |

| Weight |

1.2 kg |

- Real-Time Synchronization: μs-level cycle times ensure precise motion coordination in high-speed applications like packaging and printing.

- Flexible Programming: Supports IEC 61131-3 languages (Ladder Logic, Structured Text) for custom motion profiles.

- Energy Efficiency: Integrated power supply with regenerative braking reduces energy consumption by up to 25%.

- Reliability: IP65-rated housing and EMI shielding protect against harsh industrial environments.

- Packaging Machinery: Coordinates robotic arms and conveyors for high-speed labeling and sorting.

- Textile Manufacturing: Manages multi-axis looms and cutting machines with sub-millimeter accuracy.

- Automotive Assembly: Controls welding robots and assembly lines in automotive plants.

Case Study: A European packaging company reduced cycle times by 18% using the MAX-4/11/03/128/08/1/1/00 in their high-speed filling lines, achieving 99.9% motion accuracy.

Compared to similar controllers, the MAX-4/11/03/128/08/1/1/00 offers:

- Higher Axis Density: Supports up to 40 axes in a compact footprint.

- Integrated Power Supply: Eliminates external components, reducing installation costs by 15%.

- Advanced Diagnostics: Real-time error correction and remote monitoring capabilities.

- Axis Requirements: Verify the 40-axis limit aligns with your system’s needs.

- Communication Protocols: Ensure compatibility with your PLC’s fieldbus (e.g., PROFIBUS DP).

- Budget: Balance performance needs with cost, noting its competitive price-to-feature ratio.

- Installation: Follow ELAU’s guidelines for proper grounding and cable routing.

- Cooling: Maintain adequate airflow to prevent overheating in high-duty cycles.

- Firmware Updates: Regularly update firmware for optimal performance and security.

山西鑫业达国际贸易有限公司 (Shanxi Xinyeda International Trade Co., Ltd.) is your trusted partner for

ELAU MAX-4/11/03/128/08/1/1/00 and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide