Description

The

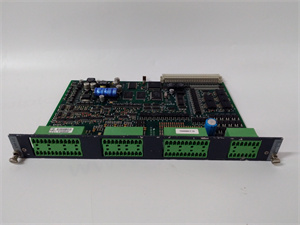

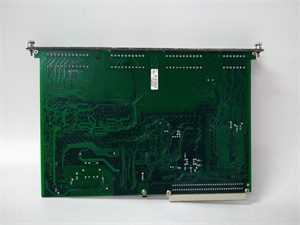

DEIF IOM4.2 is a versatile Input/Output (I/O) module designed to enhance the connectivity and control capabilities of industrial systems. Engineered by DEIF, a leading provider of power management solutions, the

DEIF IOM4.2 serves as a critical bridge between field devices and control systems, enabling seamless data exchange and precise operation in complex automation setups.

This module offers a mix of analog and digital I/O channels, allowing it to interface with sensors, actuators, and other peripheral devices. The DEIF IOM4.2 is built to handle a wide range of industrial applications, from monitoring generator set parameters to controlling process variables in manufacturing lines. Its robust design and flexible configuration make it an ideal choice for users seeking a reliable, easy-to-integrate I/O solution that simplifies system management and improves operational efficiency.

| Parameter |

Specification |

| Input Voltage |

24 VDC (±20%) |

| Power Consumption |

< 5 W (at nominal voltage) |

| I/O Channels |

4 analog inputs, 2 analog outputs, |

|

8 digital inputs, 4 digital outputs |

| Analog Input Range |

0–10 VDC, 4–20 mA (configurable) |

| Analog Output Range |

0–10 VDC, 4–20 mA (selectable) |

| Digital Input Type |

Optically isolated, 24 VDC logic |

| Digital Output Type |

Relay contact (250 VAC/2 A resistive load) |

| Communication Interface |

RS485 (Modbus RTU), Ethernet (Modbus TCP) |

| Operating Temperature |

-25°C to +70°C |

| Dimensions (W×H×D) |

100 mm × 120 mm × 50 mm |

| Certifications |

CE, RoHS, IP20 (protected against solid objects) |

DEIF IOM4.2

- Flexible I/O Configuration: The DEIF IOM4.2 offers a customizable mix of analog and digital channels, allowing users to tailor the module to their specific application needs. Its software-configurable input/output ranges eliminate the need for hardware reconfiguration, reducing setup time by up to 40% compared to fixed-function modules.

- Reliable Data Transmission: Equipped with advanced noise suppression and signal conditioning, the module ensures accurate data acquisition even in high-electromagnetic environments. Its isolated I/O channels protect against voltage spikes, enhancing system reliability and longevity.

- Seamless Integration: The DEIF IOM4.2 supports standard industrial protocols like Modbus, enabling easy integration with PLCs, HMIs, and SCADA systems. Its plug-and-play design and intuitive configuration software simplify installation, making it suitable for both new setups and retrofitting existing systems.

- Wide Environmental Tolerance: Built to withstand harsh industrial conditions, the module operates reliably across a broad temperature range and resists vibrations and humidity, making it ideal for offshore, manufacturing, and power generation applications.

- Applicable Industries: The DEIF IOM4.2 is widely used in power generation, marine engineering, industrial automation, and process control sectors. It excels in scenarios requiring real-time monitoring of sensor data (e.g., temperature, pressure, voltage) and precise control of actuators (e.g., valves, motors, contactors).

- Application Case: A marine vessel’s power management system utilized the DEIF IOM4.2 to monitor engine parameters and control generator load sharing. The module’s analog inputs captured engine temperature and fuel flow data, while its digital outputs managed circuit breakers and alarm systems. This integration improved the vessel’s fuel efficiency by 15% and reduced maintenance downtime by enabling proactive fault detection through real-time data analysis.

Compared to other industrial I/O modules, the DEIF IOM4.2 stands out for its balanced combination of channel versatility, robust communication options, and environmental resilience. While some alternatives may offer basic I/O functions, they often lack the configurable signal ranges and protocol support that the DEIF IOM4.2 provides. Its superior noise immunity and wide operating temperature range also make it a more reliable choice for demanding industrial environments where competitor modules might struggle with signal interference or temperature fluctuations.

DEIF IOM4.2

- I/O Requirements: Assess your application’s needs for analog vs. digital channels, signal ranges, and output types (e.g., relay vs. solid-state). The DEIF IOM4.2 is best suited for mid-sized systems requiring a mix of measurement and control functions.

- Communication Compatibility: Ensure the module’s supported protocols (Modbus RTU/TCP) align with your existing control system. Verify network infrastructure compatibility, such as RS485 or Ethernet cabling standards, to avoid integration issues.

- Environmental Conditions: If deploying in extreme temperatures or high-vibration environments, confirm that the DEIF IOM4.2’s specifications (e.g., -25°C to +70°C operation) match your site conditions. Consider additional protective enclosures if required for outdoor or exposed installations.

- Scalability: For large-scale systems, evaluate the module’s capacity to work in conjunction with other DEIF I/O modules or third-party devices to ensure seamless expansion as your needs grow.

- Installation Safety: Always power down the system before installing or servicing the DEIF IOM4.2. Use appropriate tools to secure terminal connections and follow local electrical codes to prevent short circuits or signal interference.

- Signal Wiring: Separate power cables from communication and signal cables to minimize electromagnetic interference. Shielded cables are recommended for analog and communication lines to maintain signal integrity.

- Configuration Backup: Regularly back up module configurations using DEIF’s dedicated software to protect against data loss during firmware updates or hardware replacement. Test configurations in a controlled environment before deploying them in live systems.

- Routine Maintenance: Inspect terminal connections for signs of corrosion or looseness during periodic maintenance checks. Clean the module’s surface with a dry cloth to prevent dust accumulation that could affect heat dissipation.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide