Description

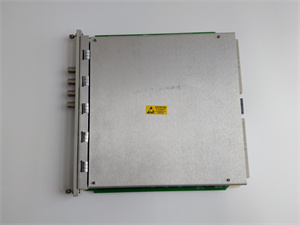

BENTLY NEVADA 3500/42M Proximitor/Seismic Monitor I/O Module

The

BENTLY NEVADA 3500/42M is a four-channel monitor designed for the 3500 Machinery Monitoring System, supporting proximity, velocity, and acceleration transducers. It converts raw sensor data into actionable insights for radial vibration, thrust position, eccentricity, and seismic activity measurements. With real-time alarm triggering and field-configurable settings, the module ensures machinery protection and predictive maintenance in industries such as oil & gas, power generation, and manufacturing. Its modular design and compatibility with legacy systems make it a versatile choice for retrofits and new installations.

| Parameter |

Specification |

| Model |

3500/42M 176449-02 |

| Channels |

4 (programmable in pairs) |

| Input Signal Range |

-10V DC to +10V DC |

| Input Impedance |

10 kΩ |

| Output Resolution |

0.3662 A per bit |

| Power Supply |

-24V DC (7.7W max) |

| Operating Temperature |

-40°C to +70°C |

| Physical Dimensions |

241.3 mm × 114.3 mm × 25.4 mm |

| Weight |

0.385 kg |

| Communication |

Modbus RTU, Ethernet (optional) |

BENTLY NEVADA 3500/42M

- Multi-Channel Flexibility: Supports up to four transducers for simultaneous monitoring of multiple parameters.

- Advanced Signal Processing: Filters noise and provides real-time data for precise machinery health assessment.

- TMR Compatibility: Integrates with Triple Modular Redundancy systems for safety-critical applications.

- Environmental Robustness: IP67-rated design withstands harsh conditions, including moisture and temperature extremes.

- Remote Configuration: Software-driven setup via 3500 Rack Configuration Tool for easy customization.

Case Study: A petrochemical plant reduced unplanned downtime by 25% using the 3500/42M to detect early signs of compressor bearing wear through continuous vibration analysis.

Industries:

- Oil & gas, power generation, manufacturing, and marine propulsion.

典型应用:

- Turbines, pumps, compressors, and rotating equipment.

Case Study: A power plant improved generator stability by 20% using the module to synchronize seismic data with grid frequency fluctuations.

The BENTLY NEVADA 3500/42M differentiates itself through:

- Dual-Channel Redundancy: Ensures continuous operation even during sensor or channel failures.

- Wide Temperature Range: Operates reliably in extreme environments compared to standard modules.

- Integrated Diagnostics: Provides self-test capabilities and fault isolation for proactive maintenance.

-

BENTLY NEVADA 3500/42M

- Multi-Parameter Monitoring: Opt for the 4-channel configuration for comprehensive machinery health tracking.

- Hazardous Areas: Choose models with ATEX/IECEx certifications for explosive environments.

- Legacy Systems: Ensure compatibility with existing 3500 racks and software versions.

- Shielding Requirements: Use shielded cables with grounding at the module end to minimize noise interference.

- Calibration Frequency: Regularly verify transducer alignment and signal integrity to maintain accuracy.

- Firmware Updates: Apply software patches to access new features and security enhancements.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 3500/42M and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide