Description

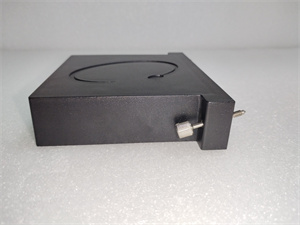

Product Specification Document for BENTLY NEVADA 170190-01E

The

BENTLY NEVADA 170190-01E is a dual-channel FieldMonitor Proximitor Input Monitor designed for critical machinery protection and condition monitoring. This device plays a vital role in detecting radial vibration and thrust position in rotating equipment such as turbines, compressors, and pumps. As part of the

BENTLY NEVADA 3300 XL Transducer System, the 170190-01E offers advanced signal conditioning, alarm setpoint configuration, and real-time data transmission to host control systems. Its embedded self-test capabilities ensure continuous integrity checks of both the monitor and connected transducers, making it a reliable choice for industrial applications.

| Parameter |

Specification |

| Channels |

2 (Dual-channel design) |

| Input Type |

Proximity probe signals |

| Signal Conditioning |

Amplification, filtering, and linearization |

| Alarm Setpoints |

User-programmable for Alert/Alarm 1 and Danger/Alarm 2 |

| Output |

4–20 mA analog signals, digital alarms |

| Power Supply |

24 V DC ±10% |

| Compatibility |

BENTLY NEVADA 3300 XL Proximitor Modules |

| Dimensions |

263 × 58 × 28 mm |

| Weight |

4.3 kg |

| Mounting Options |

Panel or DIN rail mount |

- High Reliability: Embedded self-test functionality automatically detects faults in the monitor or transducers, minimizing unplanned downtime.

- Dual-Channel Design: Simultaneously monitors two independent parameters (e.g., radial vibration and thrust position) for comprehensive machinery health assessment.

- Noise Immunity: Robust design ensures resistance to radio frequency interference (RFI), critical for accurate measurements in noisy industrial environments.

- Flexible Configuration: User-programmable alarm thresholds and signal scaling adapt to diverse machinery requirements.

- Integration: Seamless compatibility with BENTLY NEVADA’s 3300 XL and 3500 Series monitoring systems.

Industry Applications:

- Oil and Gas: Turbines, compressors, and pumps.

- Power Generation: Steam and gas turbines.

- Manufacturing: Rotating machinery in production lines.

Case Study:

A petrochemical plant integrated the BENTLY NEVADA 170190-01E into its compressor monitoring system. By detecting early-stage bearing wear through vibration analysis, the plant reduced maintenance costs by 30% and avoided a potential $2 million production loss due to unplanned shutdowns.

Compared to similar proximity input monitors, the 170190-01E stands out with:

- Dual-Channel Efficiency: Simultaneous monitoring of two parameters in a single unit.

- Advanced Self-Diagnostics: Real-time fault detection and annunciations.

- Compact Design: Space-saving DIN rail mounting for crowded control panels.

- Compatibility: Verify compatibility with existing BENTLY NEVADA systems (e.g., 3300 XL Proximitor Modules).

- Installation Environment: Consider temperature, humidity, and vibration levels to ensure optimal performance.

- Budget: Balance features like dual-channel operation and self-test capabilities against project costs.

-

Installation: Follow electrostatic discharge (ESD) protocols and secure wiring to prevent signal interference.

-

Maintenance: Regularly inspect transducer connections and update firmware for optimal performance.

-

Safety: Ensure compliance with hazardous area certifications (e.g., ATEX, IECEx) if installed in explosive environments.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 170190-01E and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide