Description

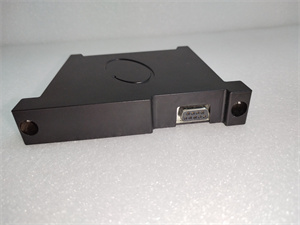

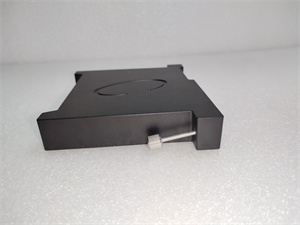

Product Specification Document for BENTLY NEVADA 170180-01-05

The

BENTLY NEVADA 170180-01-05 is a dual-channel FieldMonitor Transducer I/O Module designed for condition monitoring of rotating machinery. This module interfaces with proximitor sensors and accelerometers to provide real-time vibration and displacement measurements, ensuring early detection of machinery faults. As part of the

BENTLY NEVADA FieldMonitor System, the 170180-01-05 supports seamless integration with host control systems, offering configurable alarm thresholds and analog/digital outputs. Its compact design and robust construction make it suitable for harsh industrial environments, including hazardous areas with ATEX certification.

| Parameter |

Specification |

| Channels |

2 (Dual-channel operation) |

| Input Type |

Proximitor sensors or accelerometers |

| Input Voltage |

18–32 V DC |

| Output Signals |

0–10 V DC or 4–20 mA analog |

| Frequency Response |

10 Hz to 10 kHz |

| Accuracy |

±1% of full scale |

| Temperature Range |

-40°C to +85°C |

| Hazardous Area Rating |

ATEX II 1/3G Ex na IIC T4 (Ta=70°C) |

| Dimensions |

140 × 100 × 60 mm |

| Weight |

300 g |

| Mounting |

DIN rail or panel mount |

- Dual-Channel Efficiency: Simultaneously monitors two parameters (e.g., vibration and displacement) for comprehensive machinery health assessment.

- Wide Environmental Range: Operates reliably in extreme temperatures and high-humidity conditions.

- Hazardous Area Compliance: ATEX certification ensures safe use in explosive environments.

- Hot-Swap Capability: Enables maintenance without system shutdown.

- Built-in Diagnostics: Real-time fault detection and self-test functionality.

Industry Applications:

- Oil and Gas: Turbines, compressors, and pumps.

- Power Generation: Steam turbines and generators.

- Manufacturing: Rotating equipment in production lines.

Case Study:

A power plant integrated the 170180-01-05 to monitor steam turbine vibrations. By detecting early-stage bearing degradation, the module reduced unplanned downtime by 40% and saved $1.5 million annually through predictive maintenance.

Compared to similar I/O modules, the 170180-01-05 offers:

- Dual-Channel Flexibility: Two independent channels in a single unit.

- Enhanced Safety: ATEX certification for hazardous environments.

- Extended Temperature Range: Operates in temperatures up to +85°C.

- Compatibility: Verify compatibility with BENTLY NEVADA FieldMonitor systems.

- Installation Environment: Consider temperature, vibration, and hazardous area requirements.

- Scalability: Evaluate future expansion needs (e.g., additional channels).

-

Installation: Follow ESD protocols and secure wiring to prevent signal interference.

-

Maintenance: Regularly inspect sensor connections and update firmware.

-

Safety: Ensure compliance with local hazardous area regulations (e.g., ATEX, IECEx).

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 170180-01-05 and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide