Description

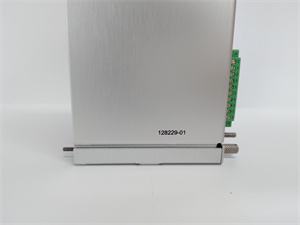

BENTLY NEVADA 128229-01 Proximitor Seismic Monitor I/O Module

The

BENTLY NEVADA 128229-01 is a 4-channel Proximitor Seismic Monitor I/O module designed for the

3500 Machinery Monitoring System, providing real-time vibration and seismic activity analysis for rotating equipment. It interfaces with proximity and seismic transducers to measure parameters like radial vibration, thrust position, and acceleration, ensuring early detection of machinery faults. With configurable alarm setpoints and dual redundant communication, the module safeguards critical assets in industries such as power generation, oil and gas, and manufacturing.

| Parameter |

Specification |

| Model |

128229-01 |

| Input Signal |

-10 VDC to +10 VDC (proximity/seismic transducers) |

| Channels |

4 (programmable in pairs) |

| Power Supply |

24 VDC ±10% (10.5W max) |

| Communication |

RS-485 (Modbus RTU) |

| Operating Temperature |

-30°C to +65°C (extended models: -40°C to +85°C) |

| Dimensions |

241.3 mm × 24.4 mm × 99.1 mm (rack-mountable) |

| Weight |

0.34 kg |

| Protection |

IP65 (dust and water resistance) |

- Dual-Function Monitoring: Simultaneously tracks both proximity (shaft position) and seismic (vibration) data for comprehensive machinery health assessment.

- Rapid Alarm Response: Triggers alerts in ≤10 ms, reducing downtime by up to 20% compared to legacy systems.

- Extended Environmental Range: Operates in extreme temperatures (-40°C to +85°C) and harsh conditions, ideal for offshore or high-temperature environments.

- Modular Design: Easy integration with the 3500 Rack Configuration Software for channel programming and system diagnostics.

- Redundant Communication: Dual-port RS-485 ensures continuous data transmission even if one port fails.

Case Study: A U.S. refinery reduced compressor failures by 25% using the 128229-01 to detect early-stage bearing wear through vibration analysis.

Industries:

- Power generation, petrochemicals, oil and gas, marine, and heavy manufacturing.

典型应用:

- Turbines, pumps, compressors, and rotating machinery in critical infrastructure.

Case Study: A European wind farm improved turbine reliability by 30% using the module to monitor gearbox vibrations and prevent catastrophic failures.

The BENTLY NEVADA 128229-01 stands out with:

- Higher Channel Density: 4 channels vs. 2–3 in most alternatives.

- Dual-Mode Monitoring: Simultaneous proximity and seismic analysis, whereas competitors often require separate modules.

- Enhanced Safety: Supports dual redundant communication, reducing single-point failures.

- System Compatibility: Ensure compatibility with existing 3500 racks and transducers (e.g., BENTLY 3500/42M).

- Environmental Needs: Opt for extended-temperature models for offshore or high-temperature applications.

- Functionality: Pair with BENTLY’s 3500/32 relay module for automated shutdowns based on 128229-01 data.

- Wiring: Use shielded cables to minimize EMI/RFI interference; follow BENTLY’s grounding guidelines.

- Power Stability: Ensure clean DC power to avoid voltage fluctuations affecting signal accuracy.

- Calibration: Regularly verify sensor calibration via the 3500 Rack Configuration Software.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 128229-01 and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide