Description

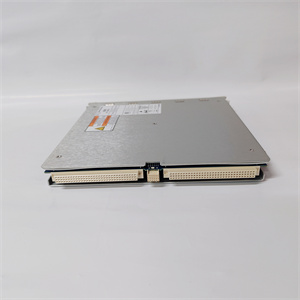

BENTLY 3500/22M 288055-01 Transient Data Interface Module

Product DescriptionThe

BENTLY 3500/22M 288055-01 is a high-performance transient data interface module designed for the

3500 Series Machinery Protection System. It serves as a bridge between the 3500 monitoring system and compatible software like

System 1 Condition Monitoring Software, enabling real-time data collection, analysis, and remote configuration. This module supports both steady-state and high-resolution transient waveform recording, making it ideal for vibration analysis, fault detection, and predictive maintenance in rotating machinery.

Key Features:

- Combines the functions of a 3500/20 Rack Interface Module (RIM) and a communication processor (e.g., TDXNet).

- Includes a built-in USB cable (unlike variant 138607-01) for convenient connectivity.

- Rugged IP67-rated housing ensures reliable operation in harsh industrial environments.

| Parameter |

Specification |

| Input Signal Range |

-10 V DC to +10 V DC |

| Power Supply |

24 V DC (dual redundancy optional) |

| Power Consumption |

10.5 W |

| Ethernet Compatibility |

10BASE-T/100BASE-TX (auto-sensing) |

| USB Interface |

USB-B front panel (integrated cable) |

| Data Storage |

16 MB for transient data |

| Operating Temperature |

0°C to +65°C (32°F to 149°F) |

| Dimensions (HxWxD) |

9.5 x 6.7 x 2.2 inches |

| Weight |

1.3 lbs (0.59 kg) |

-

Integrated Design:

- Combines RIM and communication processor roles, reducing system complexity and costs.

- Supports high-speed data capture with millisecond precision for transient waveforms.

-

Convenience:

- Built-in USB cable eliminates the need for separate purchases (unlike variant 138607-01).

- Ethernet and USB interfaces allow seamless integration with both local and remote systems.

-

Reliability:

- IP67-rated design protects against dust, moisture, and extreme temperatures.

- LED indicators provide real-time status monitoring for system health and data transmission.

-

Enhanced Data Handling:

- Stores up to 16 MB of transient data and supports up to 48 channels for comprehensive machinery analysis.

- Industries: Power generation (turbines, generators), oil and gas (compressors, pumps), manufacturing.

- Key Applications:

- Early detection of machinery faults (e.g., bearing damage, misalignment).

- Real-time vibration analysis and predictive maintenance.

- Remote monitoring of rotating equipment in critical infrastructure.

Case Study:

A petrochemical plant in the Middle East reduced maintenance costs by 25% using the BENTLY 3500/22M 288055-01 to monitor centrifugal pumps. The module’s transient data analysis identified cavitation issues before they escalated, preventing costly repairs.

Compared to legacy communication processors, the 3500/22M 288055-01 offers:

- Higher Integration: Eliminates external components, reducing installation space and complexity.

- Improved Data Resolution: Supports high-speed transient recording up to 20 kHz for detailed waveform analysis.

- Cost Efficiency: Combines multiple functions into a single module, lowering procurement and maintenance costs.

- Functionality: Choose 288055-01 for USB connectivity and standard Ethernet. Opt for fiber optic variants (e.g., 288055-02) for EMI-sensitive environments.

- Compatibility: Ensure compatibility with your 3500 rack configuration and software (e.g., System 1).

- Budget: Consider bulk discounts for large-scale deployments.

-

Installation:

- Mount in slot 1 of the 3500 rack, adjacent to power supplies.

- Ensure proper grounding using the 2-pin connector for SignalCommand integration.

-

Maintenance:

- Regularly update firmware to access new features and bug fixes.

- Monitor LED indicators for system status and data transmission errors.

-

Safety:

- Disconnect power before replacing the module to avoid electrical hazards.

Shanxi XinyeDa International Trade Co., Ltd. is your trusted partner for

BENTLY 3500/22M 288055-01 and other automation spare parts. Visit our website

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide