Description

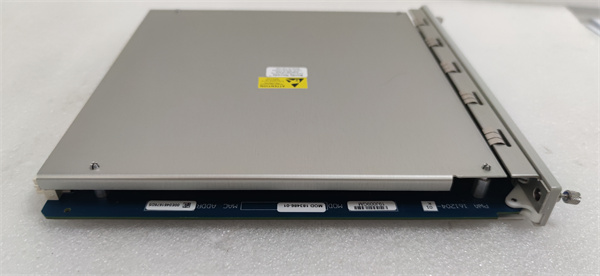

BENTLY NEVADA 3500/91 161204-01 EGD Communication Gateway Module

The

BENTLY NEVADA 3500/91 161204-01 is an Ethernet Global Data (EGD) communication gateway module designed for the BENTLY Nevada 3500 monitoring system. It bridges machinery health data with plant-wide control networks, enabling seamless integration of real-time vibration, speed, and position measurements into DCS, PLC, or SCADA systems. The module supports

10/100BASE-TX/FX Ethernet and

serial protocols (RS232/422/485), ensuring compatibility with diverse industrial setups. With

16 configurable communication channels, it streams critical parameters like vibration amplitude, bearing condition, and alarm status to facilitate predictive maintenance and optimize operational efficiency.

| Parameter |

Specification |

| Model |

3500/91 161204-01 |

| Protocol |

EGD, Modbus RTU/TCP, BENTLY Proprietary |

| Communication Speed |

10/100 Mbps |

| Input Voltage |

DC 18–36V |

| Power Consumption |

7.5W |

| Operating Temperature |

0°C to +60°C |

| Dimensions |

241.3 mm × 24.4 mm × 241.8 mm (9.50” × 0.96” × 9.52”) |

| Weight |

0.79 kg (1.75 lbs) |

| Mounting |

3500 series rack-mounted |

- Multi-Protocol Flexibility: Supports EGD, Modbus, and BENTLY’s proprietary protocols for universal connectivity.

- Real-Time Diagnostics: Provides configurable alarms and fault detection to reduce unplanned downtime by up to 30%.

- Wide Environmental Range: Operates reliably in harsh conditions (0°C to +60°C, 0–95% humidity).

- Hot-Swap Capability: Enables maintenance without system shutdown.

Case Study: A European chemical plant reduced vibration-related failures by 25% using the 3500/91 161204-01 to integrate compressor health data into their predictive maintenance platform.

Industries:

- Oil and gas, power generation, chemical, manufacturing, and mining.

- Turbines, pumps, compressors, and rotating machinery in critical infrastructure.

Case Study: A U.S. power plant improved generator efficiency by 15% by using the module to monitor stator vibrations and adjust cooling systems dynamically.

The BENTLY NEVADA 3500/91 161204-01 outperforms standard gateways with:

- Dual Ethernet Support: Simultaneous 10/100BASE-TX and FX connectivity for redundant networks.

- Higher Channel Density: 16 channels vs. 8–12 in most competitors.

- Enhanced Security: CSA/NRTL/C certification for hazardous environments.

- System Integration: Ideal for retrofitting older BENTLY 3500 systems into modern Ethernet-based control networks.

- Hazardous Areas: Choose this module for compliance with safety standards in explosive atmospheres.

- Budget Efficiency: Offers advanced features at a lower cost compared to fully redundant solutions.

- Network Configuration: Ensure proper IP addressing and subnet settings to avoid communication conflicts.

- Power Stability: Use a filtered power supply to prevent voltage spikes.

- Firmware Updates: Regularly update firmware via BENTLY’s Insight software to access new protocols and bug fixes.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 3500/91 161204-01 and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide