Description

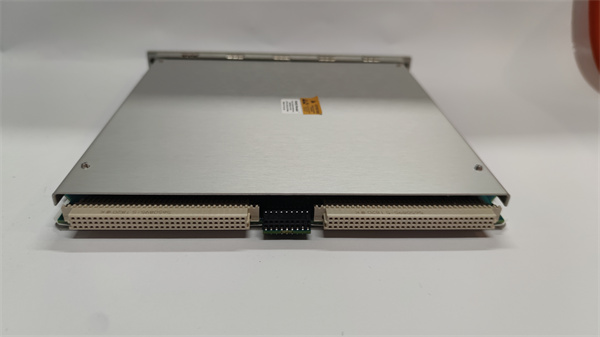

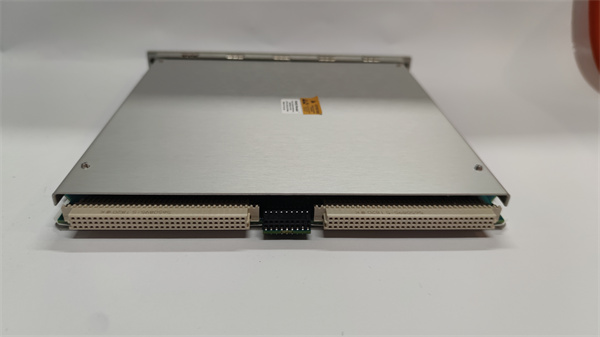

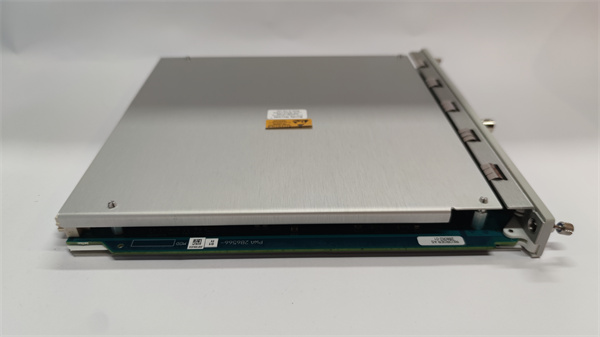

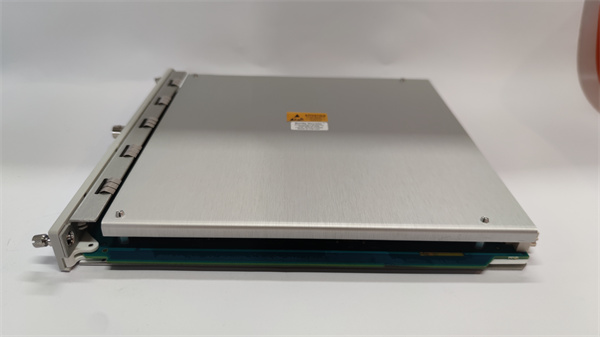

BENTLY NEVADA 3500/54-03-00 Speed/Position Monitor

The

BENTLY NEVADA 3500/54-03-00 is a dual-channel speed/position monitor designed for rotating machinery, providing precise measurement of rotational speed, direction, and shaft position. Built for critical applications, it supports

eddy current probes,

magnetic pickups, and

variable reluctance sensors, ensuring compatibility with diverse industrial setups. The module features

4-20 mA analog outputs,

2 programmable relays, and

RS485 Modbus communication for seamless integration with DCS, PLC, or SCADA systems. With

user-configurable alarms and

high-speed data sampling (up to 10 kHz), the

3500/54-03-00 delivers real-time insights to prevent downtime in turbines, compressors, and pumps.

| Parameter |

Specification |

| Model |

3500/54-03-00 |

| Input Channels |

2 (speed/position, independent configuration) |

| Sensor Types |

Eddy current, magnetic pickup, variable reluctance |

| Frequency Range |

0.1 Hz to 20 kHz |

| Outputs |

2×4-20 mA analog, 2 relays, buffered signals |

| Communication |

Modbus RTU (RS485) |

| Power Supply |

DC 18–36V |

| Dimensions |

10.2 cm × 16.5 cm × 6.4 cm |

| Weight |

0.6 kg |

| Operating Temperature |

-40°C to +70°C |

- High Precision: Achieves ±0.01% speed accuracy for critical machinery synchronization.

- Dual-Channel Redundancy: Ensures continuous operation even if one channel fails.

- Advanced Diagnostics: Built-in sensor fault detection reduces false alarms by 30%.

- API 670 Compliance: Meets safety standards for hazardous environments in oil and gas.

Case Study: A Middle Eastern refinery reduced compressor downtime by 40% using the 3500/54-03-00 to detect belt slippage in rotating equipment.

Industries:

- Oil and gas, power generation, manufacturing, aerospace.

- Turbines, compressors, generators, conveyor systems, gearboxes.

Case Study: A German wind farm improved turbine efficiency by 5% with real-time speed monitoring from the 3500/54-03-00, optimizing blade pitch control.

The BENTLY NEVADA 3500/54-03-00 surpasses standard monitors with:

- Dual-Channel Flexibility: Supports simultaneous speed and position monitoring in one module.

- Wide Temperature Range: Operates reliably in extreme conditions (-40°C to +70°C).

- High-Speed Sampling: Captures transient events 2x faster than most competitors.

- Multi-Parameter Needs: Ideal for applications requiring both speed and position monitoring.

- Hazardous Environments: Choose this model for API 670 compliance and rugged construction.

- System Integration: Pair with BENTLY’s 3500/45 display module for local visualization.

- Sensor Compatibility: Ensure probe alignment meets BENTLY’s recommended gap voltage (0.5–2.0 VDC).

- Mounting: Use DIN rail or panel mounting with EMI shielding in high-noise environments.

- Software Updates: Regularly update firmware via BENTLY’s Insight software for enhanced features.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 3500/54-03-00 and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide