Description

The

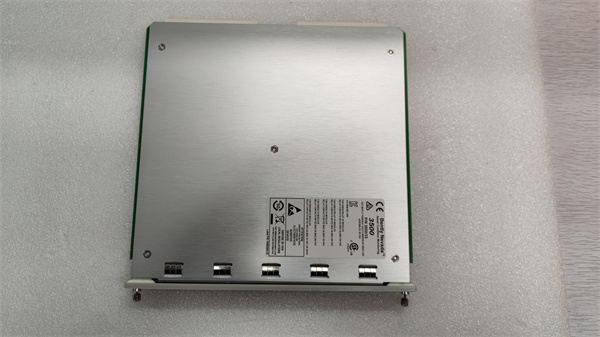

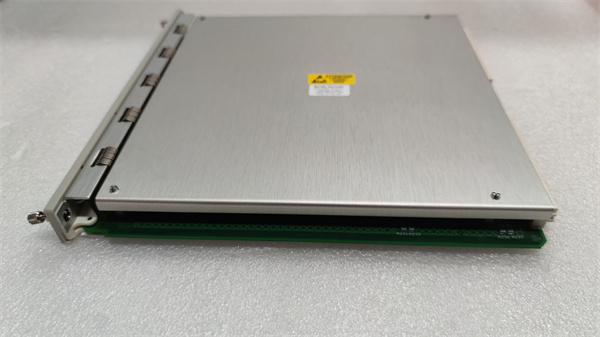

BENTLY 3500/33-1-00 is a high-performance monitoring module designed as part of the Bently Nevada 3500 Series, a leading platform for machinery protection and condition monitoring in industrial applications. This module is engineered to accurately measure and process key parameters for rotating machinery, ensuring reliable operation and preventing unexpected downtime.

The BENTLY 3500/33-1-00 specializes in handling speed, direction, and keyphasor measurements, making it ideal for critical applications where precise rotational data is essential. It interfaces seamlessly with various sensors, such as magnetic pickups or proximity probes, to capture real-time machinery dynamics. With its robust design and advanced signal processing capabilities, the BENTLY 3500/33-1-00 empowers users to monitor equipment health, optimize performance, and implement predictive maintenance strategies effectively.

| Parameter |

Specification |

| Module Type |

Speed and Keyphasor Monitoring Module |

| Input Channels |

1 channel for speed/keyphasor input |

| Sensor Compatibility |

Magnetic pickups, proximity probes (AC or DC coupled) |

| Frequency Range |

0.1 Hz to 50 kHz (depending on sensor type) |

| Output Signals |

Analog: 4-20 mA (isolated, two-wire)

Digital: Serial communication via 3500 backplane |

| Power Supply |

24 VDC ±10%, from 3500 system rack |

| Operating Temperature |

-40°C to +85°C (-40°F to +185°F) |

| Communication Interface |

3500 System Data Highway (SDH) for module-to-system connectivity |

| Physical Dimensions |

Standard 3500 rack-mountable size (1.25 inches wide) |

Bently 3500/33-1-00

The BENTLY 3500/33-1-00 stands out for its exceptional accuracy and reliability in harsh industrial environments. It incorporates advanced signal conditioning to filter noise and ensure stable measurements, even in high-vibration or high-electromagnetic interference (EMI) settings. The module’s adaptive signal processing algorithms automatically adjust to varying machinery speeds, providing consistent data across the entire operational range.

One of its key strengths is seamless integration with the 3500 Series ecosystem, allowing users to combine it with other 3500 modules (e.g., vibration monitors, temperature controllers) for a comprehensive machinery health monitoring system. This modular design reduces installation complexity and enables easy expansion as system requirements evolve. Additionally, the module supports both analog and digital outputs, ensuring compatibility with legacy and modern control systems.

The BENTLY 3500/33-1-00 is widely used in industries such as power generation, oil and gas, chemical processing, and manufacturing, where rotating machinery like turbines, compressors, and pumps are critical to operations. It is particularly suited for applications requiring precise speed control, synchronizing machinery, or detecting rotational anomalies that could indicate impending failures.

Case Study: A large petrochemical plant deployed the BENTLY 3500/33-1-00 to monitor the speed and keyphasor of a high-speed centrifugal compressor. The module’s real-time data enabled the plant to detect a subtle speed fluctuation caused by a misaligned shaft, allowing maintenance teams to address the issue before it escalated into a costly breakdown. This proactive approach reduced unplanned downtime by 30% and extended the compressor’s service life.

Compared to similar monitoring modules on the market, the BENTLY 3500/33-1-00 distinguishes itself through its superior noise immunity and wide temperature operating range, making it suitable for extreme industrial environments. Its deep integration with the 3500 Series platform also offers a more cohesive and scalable solution, as opposed to standalone modules that may require additional hardware or software adjustments for system-wide compatibility.

Bently 3500/33-1-00

When selecting the BENTLY 3500/33-1-00, consider the following:

- Compatibility: Ensure your existing system uses the 3500 Series rack and backplane to leverage full functionality.

- Sensor Type: Verify that the module supports your chosen sensors (e.g., magnetic pickups vs. proximity probes) and their output characteristics.

- Environmental Conditions: If operating in extreme temperatures or high-vibration zones, confirm that the module’s specifications align with your site’s requirements.

- Scalability: Plan for future expansions by evaluating how the module integrates with other 3500 Series components for a holistic monitoring solution.

- Installation: Mount the module in a 3500 Series rack, ensuring proper grounding to minimize EMI interference. Follow the 3500 System Installation Manual for wiring guidelines.

- Calibration: Perform initial calibration with the intended sensor to ensure accurate measurements. Regularly verify calibration during routine maintenance.

- Diagnostics: Utilize the 3500 System’s built-in diagnostics to monitor module health and detect sensor faults or communication issues promptly.

- Safety: Disconnect power before installing or servicing the module to avoid electrical hazards.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide PFEA112-65 3BSE030369R65 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide