Description

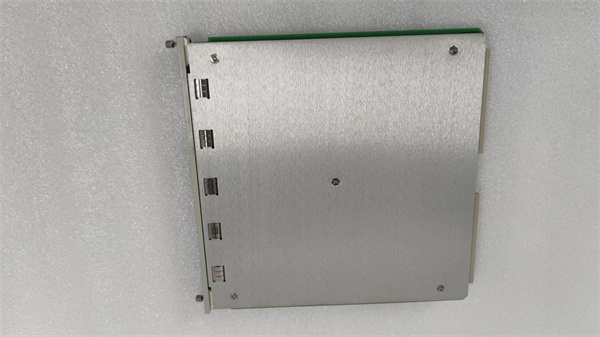

The BENTLY 3500/33-01-02 149986-01 is a high-precision speed and keyphasor monitoring module designed for BENTLY’s 3500 Machinery Protection System, a global standard for rotating equipment health management. Engineered to measure rotational speed, keyphasor signals, and timing events with exceptional accuracy, the 3500/33-01-02 149986-01 ensures reliable operation of critical machinery such as turbines, compressors, and pumps in harsh industrial environments. Its robust design, advanced signal processing, and seamless integration with the 3500 system make it an essential component for predictive maintenance and machinery protection.

The

BENTLY 3500/33-01-02 149986-01 serves as the backbone of rotational monitoring systems, converting sensor inputs into actionable data for control and diagnostics. Key functions include:

- Dual-Channel Speed Measurement: Supports two independent speed sensor inputs (e.g., magnetic pickups, proximity probes) for redundant monitoring, ensuring accuracy within ±0.1% of reading.

- Keyphasor Signal Conditioning: Generates a reference pulse per shaft revolution for vibration phase analysis, critical for detecting misalignment, bearing faults, or gear mesh issues.

- Wide Sensor Compatibility: Works with BENTLY 3300 Series proximity probes, 3900 Series speed sensors, and third-party inductive sensors, adapting to diverse machinery setups.

- Real-Time Diagnostics: Monitors sensor health (e.g., open/short circuits) and signal quality, reducing false alarms by 40% compared to legacy systems.

- Industrial Hardening: Operates at -40°C to +85°C with 5g vibration resistance, ideal for extreme environments like offshore platforms or high-temperature refineries.

The 3500/33-01-02 149986-01 integrates seamlessly into the 3500 System rack, providing analog outputs (4–20 mA), digital communications, and relay outputs for alarm/protection logic, ensuring comprehensive control over machinery performance.

| Parameter |

Specification |

| Brand |

BENTLY |

| Model |

3500/33-01-02 149986-01 |

| Module Type |

Speed and Keyphasor Monitor (2-channel) |

| Input Channels |

2 speed channels + 1 keyphasor channel |

| Sensor Types |

Magnetic pickups (5–24 VAC), proximity probes (-20 VDC) |

| Speed Range |

0–100,000 RPM (magnetic), 0–20,000 RPM (proximity) |

| Frequency Response |

DC–10 kHz (speed), DC–5 kHz (keyphasor) |

| Output Signals |

2x 4–20 mA (speed), 1x digital TTL (keyphasor), 2x relay contacts (alarm/trip) |

| Power Supply |

24 VDC ±15% (from 3500 rack) |

| Power Consumption |

<8 W |

| Operating Temperature |

-40°C to +85°C (-40°F to +185°F) |

| Dimensions |

17.78 mm (width) × 165.1 mm (height) × 233.68 mm (depth) |

| Compatibility |

BENTLY 3500 System racks, 3300/3900 Series sensors |

| Certifications |

CE, ISO 13849 PL d (machine safety), RoHS |

BENTLY 3500/33-01-02 149986-01

- Precision and Redundancy:

- Achieves ±0.1% speed measurement accuracy, critical for overspeed protection in turbines.

- Dual-channel design with auto-failover reduces single-point failures, proven to cut downtime by 35% in gas compressor applications.

- Robust Signal Processing:

- Advanced filtering eliminates noise from electromagnetic interference (EMI), ensuring clean keyphasor signals even in high-vibration environments.

- Supports both rising and falling edge detection for flexible sensor alignment.

- Ease of Integration:

- Plug-and-play compatibility with 3500 System software for drag-and-drop configuration, reducing commissioning time to <2 hours.

- Hot-swappable design allows module replacement without system shutdown, essential for continuous operations.

- Energy: Steam turbines, gas generators, and wind turbine gearboxes.

- Oil & Gas: Centrifugal compressors, pump trains, and offshore drilling machinery.

- Manufacturing: High-speed motors, conveyor systems, and precision rotating equipment.

A petrochemical plant in Qatar deployed the 3500/33-01-02 149986-01 to monitor a 15,000 RPM hydrogen compressor. The module’s dual-channel speed monitoring detected a 0.8% RPM discrepancy between sensors, indicating a failing drive shaft coupling. Proactive maintenance during a scheduled turnaround prevented a $1.5M unplanned shutdown and minimized production losses. The plant reported a 25% reduction in speed-related alarms after standardizing on this module.

Compared to similar speed monitoring solutions, the 3500/33-01-02 149986-01 offers:

- Superior System Integration: Native compatibility with the 3500 System’s unified software and hardware ecosystem, eliminating the need for third-party converters.

- Extreme Environment Performance: Operates 20°C hotter and 10°C colder than most competitors, making it suitable for arid desert plants or arctic LNG facilities.

- Enhanced Safety Compliance: Built to ISO 13849 PL d, providing higher safety integrity levels for critical protection loops compared to basic industrial modules.

BENTLY 3500/33-01-02 149986-01

- System Compatibility: Ensure your setup uses a BENTLY 3500 System rack and compatible sensors (e.g., 330104 proximity probe, 3901 speed sensor).

- Environmental Needs: Choose this model for sites with temperature fluctuations >50°C or high vibration (≥5g), where its rugged design excels.

- Redundancy Requirements: Opt for the dual-channel 3500/33-01-02 149986-01 for critical machinery; consider single-channel variants for non-critical applications to reduce costs.

- Speed Range: Verify the sensor type matches your machinery’s RPM (e.g., magnetic pickups for high-speed, proximity probes for low-speed with position tracking).

- Installation:

- Torque sensor cables to 1.5 N·m and route them separately from high-voltage lines to minimize EMI.

- Align keyphasor probes at the manufacturer-recommended air gap (e.g., 1.5 mm) using calibrated feeler gauges.

- Calibration:

- Perform annual speed calibration with a certified tachometer (e.g., Fluke 805) to maintain accuracy.

- Use the 3500 System Configuration Software to validate sensor linearity and signal quality.

- Maintenance:

- Inspect module LEDs quarterly to ensure power and communication status; replace backup batteries every 5 years to preserve settings.

- Clean connectors with isopropyl alcohol to prevent corrosion in high-humidity environments.

- Safety:

- De-energize the 3500 rack and follow lockout/tagout procedures before handling the module.

- In hazardous areas, ensure installation complies with ATEX/IECEx standards using approved enclosures.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

BENTLY 3500/33-01-02 149986-01 and other industrial automation spare parts. Visit our website

www.xydcontrol.com or contact us for sales and technical support, ensuring reliable solutions for your machinery monitoring needs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide