Description

The

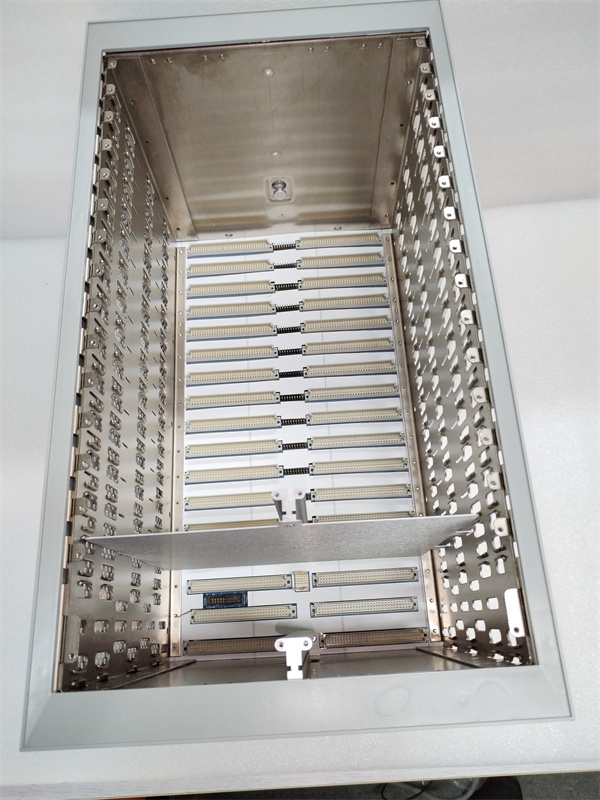

BENTLY 3500/05-01-00-00-00-01 is a critical component of the BENTLY 3500 Machinery Protection System, designed to provide robust and reliable monitoring for rotating machinery in industrial environments. As a frame assembly module, the

3500/05-01-00-00-00-01 serves as the foundational platform that integrates various monitoring functions, enabling real-time data acquisition, processing, and communication for equipment health management.

This model is engineered to house and power multiple 3500 series modules, such as sensor input modules, communication gateways, and auxiliary devices, ensuring seamless coordination within the system. Its primary purpose is to support the monitoring of key parameters like vibration, shaft position, temperature, and pressure, which are essential for preventing machinery failures and optimizing operational efficiency. The BENTLY 3500/05-01-00-00-00-01 stands out for its modular design, which allows for easy installation, maintenance, and expansion, making it a versatile choice for complex industrial setups.

| Parameter |

Specification |

| Model Number |

3500/05-01-00-00-00-01 |

| Brand |

BENTLY |

| System Type |

Machinery Protection System Frame Assembly |

| Power Supply |

100–240 V AC, 50/60 Hz, 20 W maximum |

| Dimensions (W x H x D) |

17.78 cm x 48.26 cm x 30.48 cm (7 x 19 x 12 inches) |

| Weight |

Approximately 4.5 kg (10 lbs) |

| Operating Temperature |

-40°C to +70°C (-40°F to +158°F) |

| Storage Temperature |

-40°C to +85°C (-40°F to +185°F) |

| Input Voltage Range |

85–264 V AC (universal input) |

| Module Slots |

14 slots (including power supply and communication slots) |

| Compatibility |

All BENTLY 3500 series monitoring modules |

| Communication Interfaces |

Serial (RS-232/485), Ethernet (10/100 Mbps) |

BENTLY 3500/05-01-01-00-00-01

The BENTLY 3500/05-01-00-00-00-01 offers several key advantages that make it a preferred choice for industrial machinery monitoring:

- High Reliability: Built with rugged materials and redundant power supply capabilities, the frame assembly ensures continuous operation even in harsh environments, with a mean time between failures (MTBF) exceeding 100,000 hours.

- Modular Design: The 14-slot configuration allows users to customize the system by adding or replacing modules without shutting down the entire system, reducing downtime and maintenance costs.

- Flexible Power Options: The universal input voltage range eliminates the need for specialized power adapters, making it suitable for global installations.

- Advanced Diagnostics: Integrated self-test features continuously monitor the health of the frame and connected modules, providing early warnings for potential issues.

The BENTLY 3500/05-01-00-00-00-01 is widely used in industries requiring precise machinery monitoring, including:

- Energy Production: Power plants (coal, gas, nuclear) for monitoring turbines, generators, and pumps.

- Manufacturing: Industrial facilities for tracking the health of motors, compressors, and conveyor systems.

- Oil and Gas: Offshore platforms and refineries for ensuring the reliability of critical rotating equipment.

Case Study: A large petrochemical plant in the Middle East integrated the 3500/05-01-00-00-00-01 into their compressor monitoring system. By combining the frame assembly with vibration and temperature modules, the plant achieved a 30% reduction in unplanned downtime. The modular design allowed quick replacement of a faulty module during a scheduled shutdown, avoiding costly production interruptions.

Compared to similar frame assemblies in the market, the BENTLY 3500/05-01-00-00-00-01 distinguishes itself through:

- Superior Compatibility: Seamless integration with the entire 3500 series ecosystem, offering more module options than many competing systems.

- Wide Temperature Range: Operational capability in extreme environments, outperforming alternatives that have narrower temperature specifications.

- Ease of Expansion: The 14-slot design provides ample room for future upgrades, making it a cost-effective long-term solution.

BENTLY 3500/05-01-01-00-00-01

When selecting the BENTLY 3500/05-01-00-00-00-01, consider the following:

- System Requirements: Evaluate the number of monitoring parameters and modules needed to ensure the frame has sufficient slots for current and future needs.

- Environmental Conditions: Confirm that the operating temperature, humidity, and vibration levels of your facility fall within the product’s specifications.

- Budget and Scalability: While the modular design offers flexibility, factor in the cost of additional modules and whether the frame’s expansion capacity aligns with your long-term plans.

To ensure optimal performance and safety when using the BENTLY 3500/05-01-00-00-00-01:

- Power Safety: Always disconnect the power supply before installing or removing modules to prevent electrical hazards.

- Static Protection: Use anti-static wrist straps and mats when handling internal components to avoid damage from electrostatic discharge.

- Regular Maintenance: Schedule periodic inspections to clean dust and debris from the frame and check for loose connections, especially in high-vibration environments.

- Software Compatibility: Ensure that the firmware and configuration software are up to date to maintain full functionality with all connected modules.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide PFEA112-65 3BSE030369R65 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide