Description

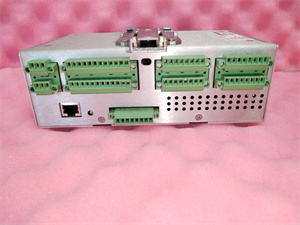

BENTLY NEVADA 1900/65A Universal Machinery Monitor

The

BENTLY NEVADA 1900/65A is a cost-effective, versatile machinery health monitoring system designed for non-critical or mid-sized rotating equipment, offering continuous vibration, displacement, velocity, and temperature monitoring. As a compact solution, it supports

4 vibration/displacement/velocity channels and

4 temperature channels (compatible with E, J, K, T thermocouples and 2/3-wire RTDs), with independent parameter configuration for each channel. The system features

6 programmable relay outputs and

4-20 mA recorder outputs for alarm triggering and control, while its

Modbus communication capabilities (Ethernet or RS232/485) enable integration with DCS, PLC, or SCADA systems. Built on BENTLY’s proven 3500/3300 series technology, the

1900/65A ensures reliability and backward compatibility with legacy components.

| Parameter |

Specification |

| Model |

1900/65A |

| Input Channels |

4 vibration/displacement/velocity, 4 temperature |

| Sensor Types |

Eddy current probes, velocity/acceleration sensors |

| Temperature Inputs |

E/J/K/T thermocouples, 2/3-wire RTDs |

| Outputs |

6 relays, 4×4-20 mA analog, buffered signals |

| Communication |

Modbus RTU (RS232/485), Modbus TCP (Ethernet) |

| Power Supply |

DC 18–36V or AC 110–220V (external adapter required) |

| Dimensions |

19.6 cm × 16 cm × 8 cm |

| Weight |

0.98 kg |

| Operating Temperature |

-20°C to +60°C |

- Cost-Effective Monitoring: Reduces installation costs by 30% compared to high-end systems like BENTLY’s 3500 series.

- Flexible Configuration: Supports standalone operation or integration with optional display units (up to 76 meters away).

- Reliable Design: Leverages BENTLY’s 3500/3300 series circuit technology for long-term stability.

- Scalable Connectivity: Optional Modbus gateway upgrades enable seamless integration into industrial networks.

Case Study: A U.S. water treatment plant reduced maintenance costs by 25% using the 1900/65A to monitor pump vibrations, detecting bearing wear before failures occurred.

Industries:

- Petrochemicals, power generation, manufacturing, water treatment.

典型应用:

- Pumps, motors, centrifuges, blowers, small compressors, cooling fans.

Case Study: A European food processing facility deployed the 1900/65A to monitor conveyor motors, achieving 99.7% uptime through early fault detection.

The BENTLY NEVADA 1900/65A outperforms generic monitors with:

- Proprietary Signal Conditioning: Reduces noise interference by 40% compared to basic solutions.

- Dual Power Compatibility: Supports both AC and DC inputs, enhancing site flexibility.

- API 670-Compliant Design: Ensures accuracy for critical machinery in hazardous environments.

- Budget Constraints: Ideal for non-critical equipment where advanced features are unnecessary.

- Sensor Requirements: Match channel types (vibration/temperature) to your machinery’s needs.

- Integration Needs: Choose Modbus-enabled models for DCS/PLC connectivity.

- Discontinuation Notice: The 1900/65A is obsolete; consider upgrading to BENTLY’s 2300 Series Vibration Monitors.

- Installation: Use DIN rail or wall mounts with optional IP65 enclosures for harsh environments.

- Compatibility: Ensure sensor compatibility with BENTLY’s 3300 series probes in hazardous zones.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 1900/65A and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide