Description

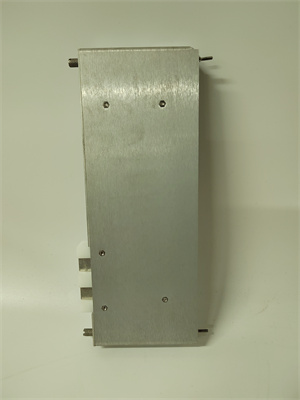

BENTLY NEVADA 136719-01 Barrier Earth Module

The

BENTLY NEVADA 136719-01 is a compact, half-height, two-channel

Barrier Earth Module designed for the

3500 Series Machinery Protection System. It provides electrical isolation and intrinsic safety interfaces to protect sensitive electronics from voltage spikes, electromagnetic interference (EMI), and explosive environments. This module supports input from proximity probes, seismic transducers, and magnetic pickups, making it critical for vibration monitoring and condition diagnostics in rotating machinery.

| Parameter |

Specification |

| System Compatibility |

BENTLY NEVADA 3500 Series Monitoring System |

| Input Signal Types |

Proximity probes, magnetic pickups |

| Voltage Range |

10–30 V DC |

| Current Rating |

0–20 mA (continuous) |

| Output Relays |

SPST NO (10 A at 240 V AC) |

| Temperature Range |

-40°C to +85°C (operating) |

| Dimensions |

89 mm × 89 mm × 25 mm (W × H × D) |

| Weight |

0.2–0.4 kg |

- Intrinsic Safety: Equipped with internal barriers to prevent explosions in hazardous environments (e.g., petrochemical plants).

- Dual Functionality: Supports both vibration monitoring (via proximity probes) and seismic measurements (via transducers).

- Compact Design: Lightweight and space-efficient for easy integration into existing systems.

- Wide Compatibility: Works with BENTLY’s 3300/3500 sensors and the System 1 software for predictive maintenance.

- Industries: Power generation, oil & gas, manufacturing, and petrochemicals.

- Use Cases:

- Grounding and signal isolation for vibration sensors in turbines and compressors.

- Monitoring axial displacement, eccentricity, and speed in rotating machinery.

- EMI protection in high-noise industrial settings.

- Safety Compliance: Meets ATEX, CE, and UL standards for hazardous environments.

- Flexibility: Supports multiple sensor types (e.g., eddy current, magnetic) compared to single-function alternatives.

- Cost-Effective: Reduces installation complexity and panel space.

- Hazardous Environments: Ideal for zones with explosive gas or dust.

- Vibration-Critical Machinery: Use with BENTLY’s 3300/3500 probes for precise diagnostics.

- Space Constraints: Choose this module for compact installations.

- Proper Installation: Follow guidelines for grounding to avoid ground loops.

- Temperature Limits: Ensure operating conditions stay within -40°C to +85°C.

- Maintenance: Regularly inspect terminals for corrosion or loose connections.

Supplier: Shanxi XinyeDa International Trade Co., Ltd. offers genuine BENTLY NEVADA modules. For inquiries, visit

www.xydcontrol.com or contact their technical team.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide