Description

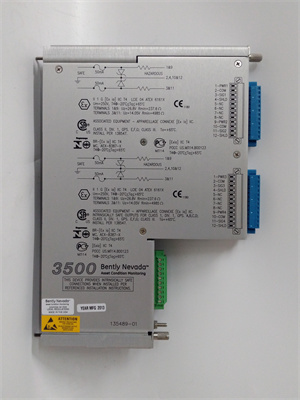

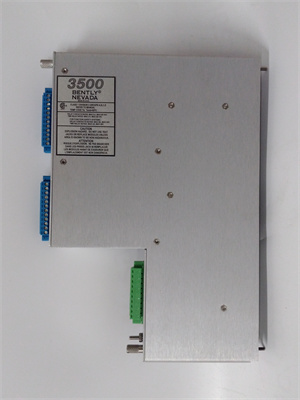

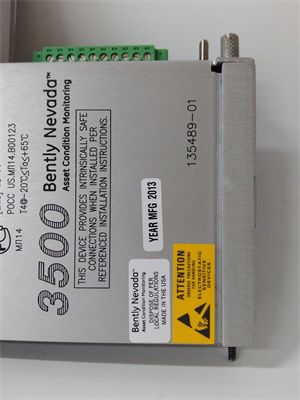

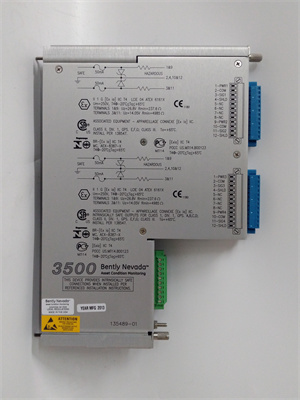

BENTLY 135489-01 4-Channel Internal Barrier I/O Module

The

BENTLY 135489-01 is a

4-channel internal barrier I/O module designed for the

3500 Machinery Protection System, ensuring explosion-proof safety in hazardous industrial environments. It interfaces with proximity probes, accelerometers, and velocity sensors while providing intrinsic safety for petrochemical, oil & gas, and power generation applications. The module integrates seamlessly into BENTLY’s 3500 racks, offering real-time vibration monitoring, overspeed detection, and redundant control. Its

internal barrier design eliminates external isolation components, reducing installation complexity and improving system reliability.

| Parameter |

Specification |

| Product Type |

3500/42 Internal Barrier I/O Module |

| Channels |

4 (Proximity/Acceleration/Velocity) |

| Input Voltage |

24 VDC ±10% |

| Temperature Range |

-40°C to +70°C (-40°F to 158°F) |

| Isolation Rating |

250 V (Field to System) |

| Bandwidth |

30 kHz (Proximity/Acceleration) |

| Amplitude Accuracy |

±3% @ 10 kHz |

| Dimensions |

241.3 mm × 24.4 mm × 163.1 mm (9.50 in × 0.96 in × 6.42 in) |

| Weight |

0.46 kg (1.01 lb) |

| Certifications |

CE, RoHS, ATEX, IECEx, API 670 |

- Explosion-Proof Design: Meets ATEX and IECEx standards for use in Zone 0/1 hazardous areas.

- Space-Saving: Integrates barriers internally, reducing rack space compared to external solutions.

- High Precision: ±1% velocity sensor accuracy and 30 kHz bandwidth for detailed vibration analysis.

- Case Study: A refinery reduced maintenance costs by 15% by retrofitting 135489-01 modules to eliminate external barrier failures.

- Industries: Oil & gas, petrochemical, power generation, and water treatment.

- Key Applications:

- Vibration monitoring of turbines, compressors, and pumps.

- Explosion-proof signal conditioning in offshore platforms.

- Redundant overspeed protection in rotating machinery.

The 135489-01 outperforms alternatives by:

- Internal Barrier Integration: Eliminates the need for external barriers, simplifying installation.

- API Compliance: Meets API 670 safety requirements for critical machinery.

- Wide Sensor Support: Compatible with BENTLY’s 3300, 7200, and Velomitor sensors.

- System Compatibility: Ensure integration with BENTLY 3500 racks and power supplies.

- Safety Requirements: Opt for redundant configurations in high-risk environments.

- Expansion: Pair with 3500/32M relay modules for alarm and shutdown functionality.

- Installation: Follow ATEX guidelines for cable routing and grounding in hazardous areas.

- Calibration: Calibrate sensors annually using BENTLY’s 3500/05 software.

- Maintenance: Replace modules every 5 years or as per API 670 recommendations.

Shanxi XinyeDa International Trade Co., Ltd. supplies

BENTLY 135489-01 and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide