Description

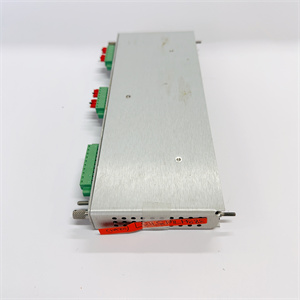

BENTLY NEVADA 135137-01 Position I/O Module

The

BENTLY NEVADA 135137-01 is a 4-channel Position I/O Module designed for integration with the

3500/45 Monitoring System, providing real-time machinery health monitoring and protection. This module accepts inputs from proximity transducers, rotary position transducers (RPTs), linear variable differential transformers (LVDTs), and rotary potentiometers, converting raw signals into actionable data for axial position, differential expansion, and valve position analysis. Its user-programmable alarm setpoints and dual-channel pairing capabilities enable precise control and early fault detection in rotating equipment.

| Parameter |

Specification |

| Model |

135137-01 |

| Input Signal |

-10 VDC to +10 VDC |

| Power Supply |

-24 VDC ±10% (external) |

| Power Consumption |

7.7 W |

| Channels |

4 (paired for dual functions) |

| Compatibility |

Proximitors, RPTs, DC/AC LVDTs, potentiometers |

| Dimensions |

241 mm × 24.4 mm × 99.1 mm (9.50” × 0.96” × 3.90”) |

| Weight |

0.44 kg (0.96 lb) |

| Operating Temperature |

-30°C to +65°C |

- Multi-Sensor Flexibility: Supports proximity, RPT, LVDT, and potentiometer inputs, reducing system complexity.

- Dual-Channel Pairing: Channels 1–2 and 3–4 can execute independent functions (e.g., axial position and case expansion).

- SIL-Compliant Redundancy: Meets IEC 61508 safety standards with redundant power supply options for critical applications.

- Predictive Maintenance: Continuous parameter comparison with configurable alarms minimizes downtime.

Case Study: A petrochemical plant reduced compressor failures by 30% using the 135137-01 to monitor axial thrust and differential expansion in high-speed turbines.

Industries:

- Power generation, oil and gas, manufacturing, and marine propulsion.

典型应用:

- Turbines, pumps, compressors, and steam turbines.

Case Study: A European power plant improved generator reliability by 25% by integrating the module to monitor shaft displacement and thermal growth in combined-cycle systems.

The BENTLY NEVADA 135137-01 outperforms alternatives with:

- Redundant Power Support: Optional n+1 power supply configuration for SIL-rated safety systems.

- Wide Temperature Range: Operates in extreme conditions (-30°C to +65°C), exceeding standard modules limited to 0°C–50°C.

- Pre-Integrated Terminations: Internal wiring reduces installation time compared to modules requiring external terminal blocks.

- System Complexity: Choose this module for multi-sensor applications needing dual-channel functionality.

- Safety Requirements: Opt for SIL-rated redundancy in high-risk environments like offshore platforms.

- Compatibility: Ensure compatibility with BENTLY’s 3500 Rack and existing automation software.

- Power Redundancy: Use redundant external power supplies for SIL applications (refer to Section 11.11 of the manual).

- Sensor Calibration: Recalibrate LVDTs and RPTs every 90 days to maintain accuracy.

- Firmware Updates: Regularly update firmware to address security patches and enhance functionality.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY NEVADA 135137-01 and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide