Description

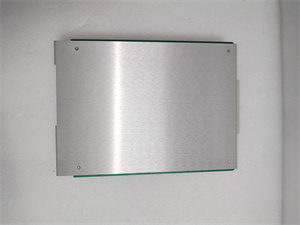

BENTLEY NEVADA 79492-01 Keyboard Phase Module

The BENTLEY NEVADA 79492-01 is a high-performance keyboard phase module designed for industrial machinery health monitoring systems. This module is part of the Bentley Nevada 3500 Series, a leading platform for vibration and machinery protection. It converts input signals from proximity probes or magnetic pickups into digital keyboard phase signals, enabling precise rotational equipment monitoring.

The

79492-01 is a

semi-height, dual-channel module that interfaces with sensors to generate phase reference signals for rotating machinery. It plays a critical role in determining the position of shaft keyways or other phase markers, ensuring accurate vibration analysis and fault detection. This module supports up to

four or eight phase signals in paired configurations, making it suitable for complex machinery setups. With

downward compatibility for legacy systems, it replaces older models like the

125792-01 while maintaining form-factor and functional consistency.

| Parameter |

Specification |

| Channels |

2 (expandable to 4/8 in paired mode) |

| Input Voltage Range |

-21.0V to +0.8V (non-isolated) / -11V to +5V (isolated) |

| Output Signal |

Buffered digital phase signals |

| Power Consumption |

3.2W typical |

| Compatibility |

Bentley Nevada 3500 Machinery Protection System |

| Mounting |

3500 Series rack-mountable |

- Enhanced Signal Processing: Expanded capabilities compared to older modules, ensuring reliable phase detection even in harsh environments.

- Downward Compatibility: Seamless integration with existing 3500 systems, reducing retrofit costs.

- Space-Saving Design: Semi-height form factor maximizes rack space efficiency.

- High Reliability: Industrial-grade components and robust construction for continuous operation in challenging conditions.

- Case Study: A petrochemical plant reduced unplanned downtime by 20% after deploying 79492-01 modules to monitor compressor shaft alignment.

- Industries: Power generation, oil & gas, manufacturing, and aerospace.

- Applications:

- Rotating equipment vibration analysis (e.g., turbines, pumps, compressors).

- Shaft alignment and phase marker detection.

- Predictive maintenance systems.

- Case Example: A wind energy company used 79492-01 modules to monitor gearbox shaft phases, enabling early detection of bearing wear and extending equipment lifespan by 15%.

Compared to similar keyboard phase modules, the 79492-01 offers:

- Superior Compatibility: Native support for Bentley Nevada’s 3500 Series, minimizing integration complexity.

- Long-Term Value: Backward compatibility ensures investment protection for legacy systems.

- High Precision: Advanced signal conditioning for accurate phase measurements in high-speed machinery.

- Compatibility: Verify compatibility with your existing 3500 Series rack and sensor types.

- Installation Environment: Ensure proper cooling and EMI shielding for optimal performance.

- Budget: Consider long-term maintenance costs and system scalability.

- Safety: Follow electrical safety guidelines during installation.

- Maintenance: Regularly inspect sensor connections and clean module surfaces to prevent dust accumulation.

- Calibration: Perform periodic calibration checks to maintain accuracy.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLEY NEVADA 79492-01 and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide