Description

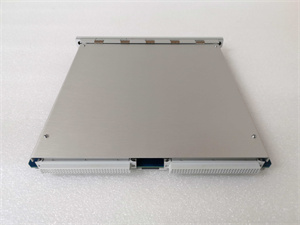

BENTLEY NEVADA 3500/92 136180-01 Communication Gateway Module

The

BENTLEY NEVADA 3500/92 136180-01 is a high-performance communication gateway module designed to integrate BENTLEY’s 3500 Series Machinery Protection System with industrial automation networks. It supports Ethernet TCP/IP and serial (RS232/RS422/RS485) protocols, enabling real-time transmission of critical machinery health data—including vibration, temperature, and speed—to SCADA, BMS, and HMI systems. With dual-channel redundancy and configurable Modbus registers, the

3500/92 136180-01 ensures reliable connectivity in harsh environments, such as power plants, chemical refineries, and manufacturing facilities. Its compact design and compatibility with legacy systems make it ideal for retrofitting or expanding existing monitoring setups.

| Parameter |

Specification |

| Model |

3500/92-01-01-00 (136180-01) |

| Protocol Support |

Modbus RS-485, Modbus/TCP, Ethernet TCP/IP, BENTLEY Proprietary |

| Ethernet Standards |

10BASE-T (RJ45) |

| Power Supply |

24 Vdc ±10% or 120/240 Vac ±10% |

| Operating Temperature |

-40°C to +70°C (-40°F to +158°F) |

| Rack Space |

1 front slot + 1 rear slot (3500 Series) |

| Redundancy |

Dual-channel support (optional) |

| Data Update Rate |

Sub-second response time |

| Weight |

0.5 kg |

- Multi-Protocol Flexibility: Seamlessly integrates with Modbus, TCP/IP, and BENTLEY’s proprietary protocols.

- Dual-Channel Redundancy: Ensures fail-safe operation in TMR configurations.

- Configurable Modbus Registers: Provides direct access to 3500 system data for legacy and modern systems.

- Wide Voltage Range: Supports both AC and DC power inputs for global compatibility.

- Real-Time Monitoring: Enables proactive maintenance through instantaneous data transmission.

- Power Generation: Connecting steam turbines to SCADA systems for remote condition monitoring.

- Oil & Gas: Integrating offshore platform compressors with BMS for safety optimization.

- Manufacturing: Transmitting motor health data to HMI for predictive maintenance in automotive plants.

Case Study: A German chemical plant reduced downtime by 25% using the 3500/92 136180-01 to monitor pump vibrations, enabling early fault detection and preventive repairs.

The 3500/92 136180-01 outperforms alternatives through:

- Native Protocol Support: Built-in compatibility with BENTLEY’s proprietary data management tools.

- Redundancy Options: Standard dual-channel redundancy for mission-critical applications.

- Modbus Flexibility: Configurable registers simplify integration with third-party systems.

- Redundancy Needs: Choose dual-channel models for systems requiring continuous operation.

- Power Source: Verify AC/DC compatibility based on site infrastructure.

- Legacy Integration: Ensure 3500 Rack Configuration Software v3.70+ for backward compatibility.

- Firmware Updates: Regularly update firmware to maintain protocol compliance.

- Network Security: Implement firewalls to protect against unauthorized access.

- Environmental Conditions: Use IP67-rated enclosures for outdoor or corrosive environments.

山西鑫业达国际贸易有限公司 specializes in

BENTLEY NEVADA 3500/92 136180-01 and automation spare parts. Visit

www.xydcontrol.com for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide