Description

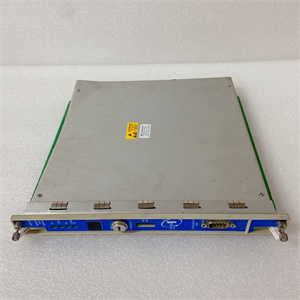

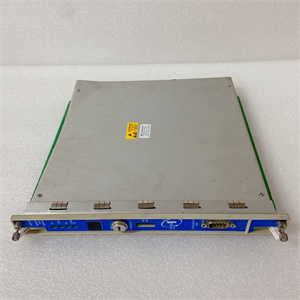

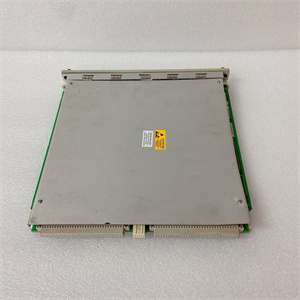

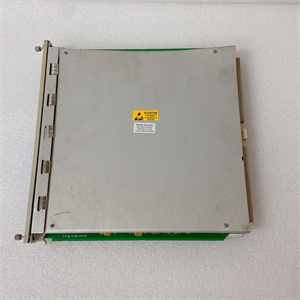

Bentley Nevada 3500/22M 138607-01 Transient Data Interface (TDI) Module

The

Bentley Nevada 3500/22M 138607-01 is a high-performance transient data interface module designed for the

3500 Series Machinery Protection System, enabling real-time monitoring and analysis of rotating equipment in industrial environments. It integrates the functions of a Rack Interface Module (RIM) and a communication processor, such as TDXnet, to collect and transmit steady-state and transient waveform data via Ethernet. This module supports up to four channels of dynamic data capture with optional disk enablement, providing high-resolution insights into machinery health for predictive maintenance. Compatibility with Bentley System 1™ software ensures seamless integration into existing automation systems.

| Parameter |

Specification |

| Data Channels |

4 dynamic channels (expandable with disk enablement) |

| Data Rate |

Up to 100 kHz (transient), 10 kHz (steady-state) |

| Interface |

Ethernet (10/100 Mbps), RS-485 for system configuration |

| Compatibility |

Bentley Nevada 3500 Monitoring System, System 1™ |

| Input Voltage |

24 VDC ±10% (from 3500/15 Power Module) |

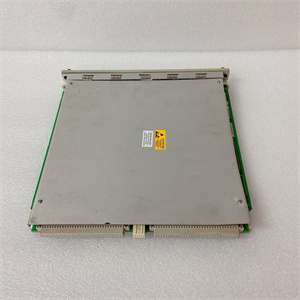

| Dimensions |

25.4 cm × 12.7 cm × 5.1 cm (10 × 5 × 2 in) |

| Weight |

0.8 kg (1.76 lb) |

| Operating Temperature |

-20°C to +60°C |

- Dual-Mode Data Capture: Simultaneously collects steady-state and transient data for comprehensive machinery diagnostics.

- High-Speed Ethernet Connectivity: Ensures rapid data transfer to 上位机软件,reducing latency for real-time decision-making.

- Compact Integration: Combines RIM and communication processor functions, eliminating the need for additional hardware.

- Scalable Configuration: Supports up to 32GB of local storage (via disk enablement) for extended data logging.

- Reliability: Meets API 670 standards and includes built-in self-diagnostics to verify signal integrity.

Industries:

- Power generation (gas/steam turbines)

- Oil and gas (pumps, compressors)

- Manufacturing (rotating machinery)

Case Study:

A North American refinery deployed the 3500/22M 138607-01 to monitor compressor vibrations. By analyzing transient data during startup, operators detected misalignment issues early, reducing downtime by 40% and extending equipment lifespan.

The 3500/22M 138607-01 outperforms standard TDI modules with:

- Integrated RIM Functionality: Eliminates separate RIM hardware, saving up to 30% in installation costs.

- Higher Data Resolution: Captures transient signals at 100 kHz, compared to 50 kHz for most competitors.

- Plug-and-Play Compatibility: Works seamlessly with Bentley’s System 1™ software, minimizing integration complexity.

- System Compatibility: Ensure compatibility with the 3500 Rack and System 1™ software.

- Data Storage Needs: Opt for disk enablement if long-term waveform logging is required.

- Redundancy: Pair with a redundant power supply module (e.g., 106M1079-01) for critical applications.

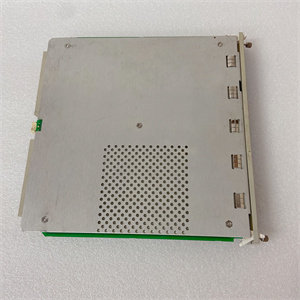

- Installation: Mount in Slot 1 of the 3500 Rack, adjacent to the power supply module.

- Wiring: Use shielded cables for transducer inputs to prevent noise interference.

- Software Configuration: Update firmware to the latest version for optimal performance and security.

Shanxi Xinyeda International Trade Co., Ltd. specializes in providing

Bentley Nevada 3500/22M 138607-01 modules and automation solutions. Visit

www.xydcontrol.com or contact us for sales, technical support, and customized industrial monitoring systems.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide