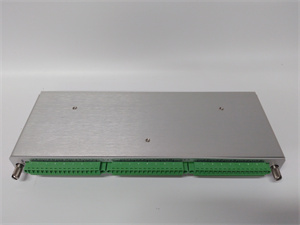

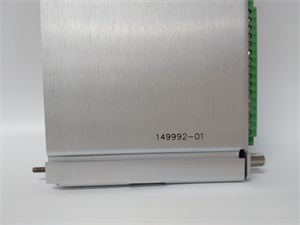

Description

The

Bentley Nevada 133819-01 is a

6-channel RTD/TC Temperature I/O Module designed for the

3500 Mechanical Health Monitoring System, specializing in real-time temperature and vibration monitoring of rotating machinery. It interfaces with resistance temperature detectors (RTDs), thermocouples (TCs), and proximity sensors to track critical parameters such as bearing temperatures, shaft vibrations, and process conditions. With modular architecture and rugged construction, it ensures reliable performance in harsh industrial environments, supporting predictive maintenance strategies.

| Parameter |

Specification |

| Input Channels |

6 (RTD/TC, non-isolated) |

| Signal Type |

RTD (Pt100, Pt500), TC (J, K, T, E, etc.) |

| Power Supply |

24 V DC ±10% |

| Operating Temperature |

-40°C to +85°C |

| Communication Protocol |

RS485 (Modbus RTU) |

| Compatibility |

Bentley Nevada 3500 Rack, System 1 Software |

| Dimensions |

Compact design for 3500 Rack integration |

- Multi-Sensor Support: Simultaneously monitors temperature (RTD/TC) and vibration via proximity probes.

- Real-Time Data Integration: RS485 connectivity enables seamless integration with central control systems for predictive analytics.

- Space Efficiency: Six channels in a single module, reducing rack space requirements.

- Intelligent Alarming: Configurable thresholds trigger alerts for abnormal temperature or vibration levels.

- Industries: Power generation (turbines, generators), oil and gas (pumps, compressors), manufacturing (motors, conveyor systems).

- Use Cases: Monitoring bearing health in rotating equipment, detecting overheating in critical machinery, and ensuring compliance with API 670 standards.

- Channel Density: 6 channels vs. typical 4–5 channels in competing modules.

- Temperature Range: Operates in extreme conditions (-40°C vs. standard -20°C).

- Integration: Native compatibility with Bentley’s 3500 system eliminates external adapters.

- Sensor Type: Choose this module for RTD/TC temperature measurements; use dedicated vibration modules for proximity probe inputs.

- System Scale: Pair with 3500/60 rack for large-scale monitoring systems.

- Remote Monitoring: Enable RS485 for integration with Bentley’s System 1 software.

- Calibration: Regularly verify sensor accuracy and update firmware.

- Installation: Follow grounding and cabling guidelines to minimize interference.

- Protocol Setup: Ensure Modbus RTU parameters match the system configuration.

Shanxi Xinyeda International Trade Co., Ltd. offers

Bentley Nevada 133819-01 and automation solutions. Visit

www.xydcontrol.com for technical support and global logistics.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide